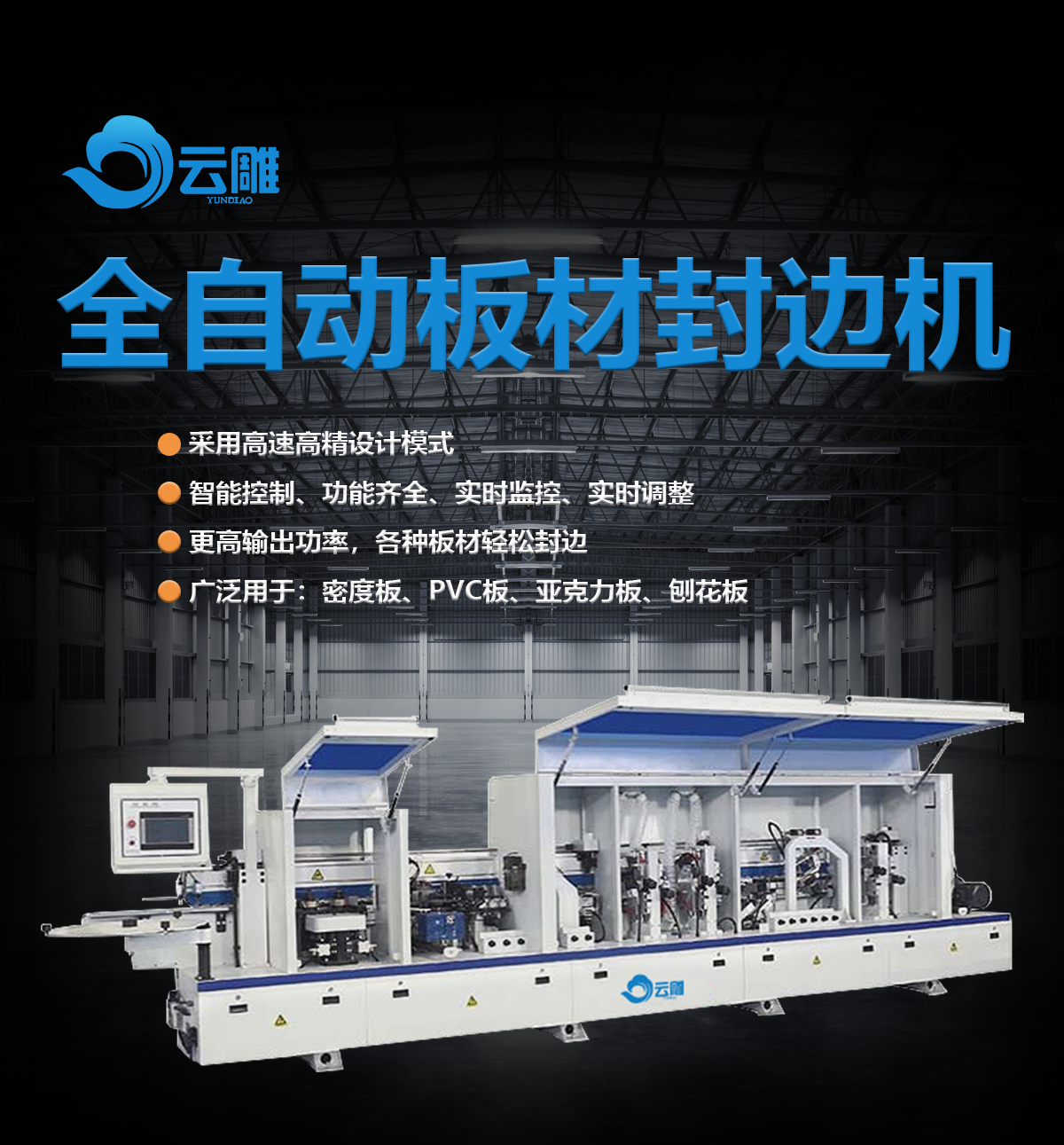

Fully automatic board edge banding machine

The fully automatic board edge banding machine is a highly automated woodworking machinery mainly used for board edge banding of panel furniture. It has the characteristics of automation, high efficiency, high precision, and aesthetics.

Product characteristics:

Category:

products

Non-standard customization

Product attachments:

Keyword:

Fully automatic board edge banding machine

contact us

Product Description

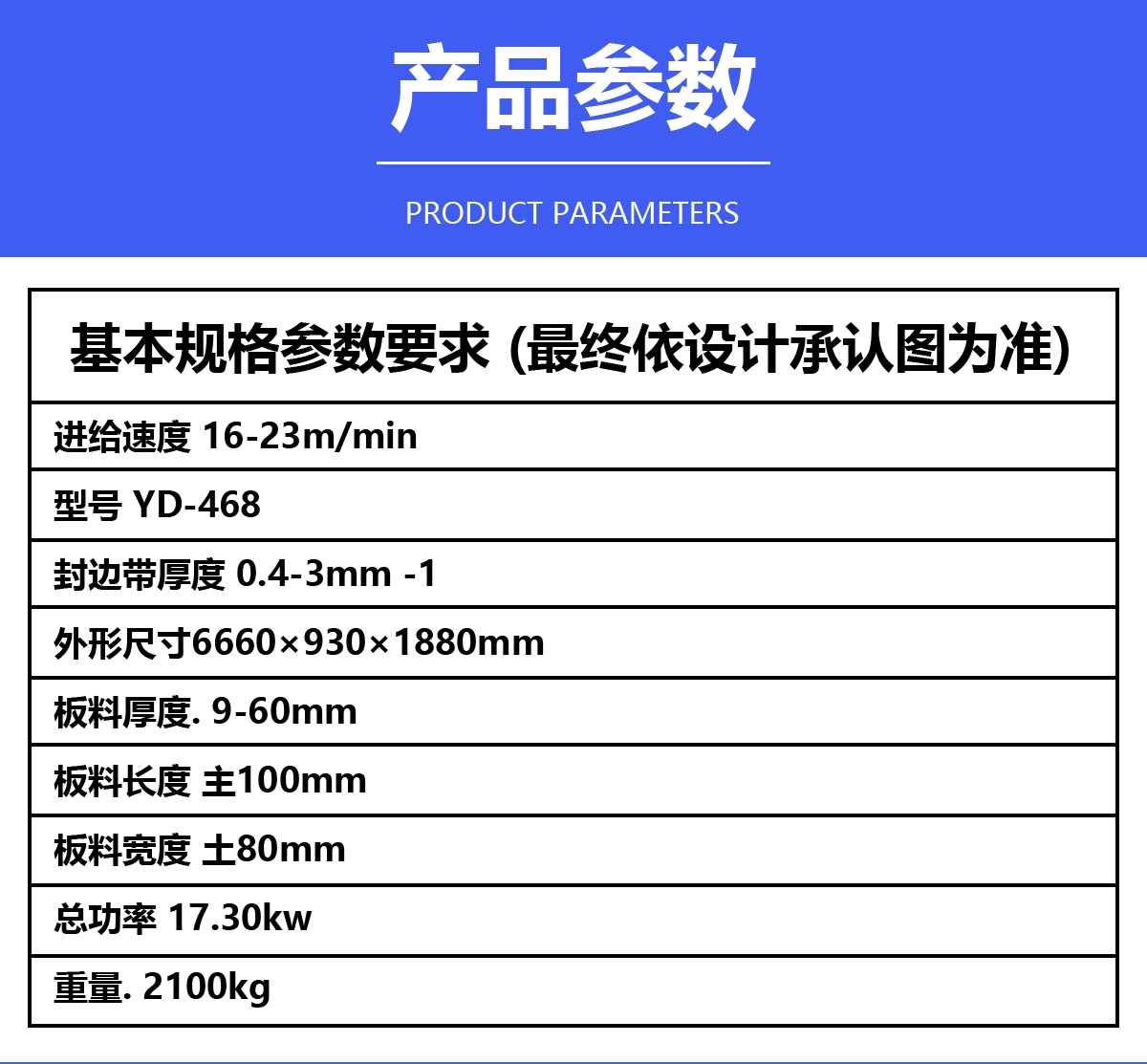

The fully automatic board edge banding machine mainly includes the body, various processing units, control system, and other parts. The processing components mainly include pre milling, gluing, edge sealing, alignment, rough trimming, precision trimming, contour tracking, scraping, polishing, slotting, etc.

Body: The most important part related to accuracy is the upper and lower crossbeams, as they are related to whether the processed sheet can run in a straight line to ensure that each processing unit can work accurately. Crossbeams are mainly divided into two types: aluminum alloy beams and cast iron beams. Among them, aluminum alloy beams are widely used in advanced models due to their superior precision and straightness compared to cast iron. The body base is usually made of steel plate laser cutting and welded in one go, which has the advantage of being firm and not deformed, thereby increasing the stability of the whole machine.

Numerical control module: Each major manufacturer can independently design it, and most of them have applied for patent protection. The feeding speed has reached the advanced level abroad. Nowadays, more advanced PLCs include LG series, Siemens series, etc.

Each component group: The structure is basically similar, and corresponding components can be added or reduced according to actual processing needs.

3、 Functional characteristics

Automated operation: The fully automatic board edge banding machine can automatically complete the edge banding process of the board, including automatic feeding, automatic hot melt bonding, automatic trimming, and automatic pressing, making the edge banding process faster, more efficient, and accurate.

High precision control: The equipment is equipped with a high-precision control system that can ensure the accuracy and precision of edge sealing, meeting the needs of different materials and processes.

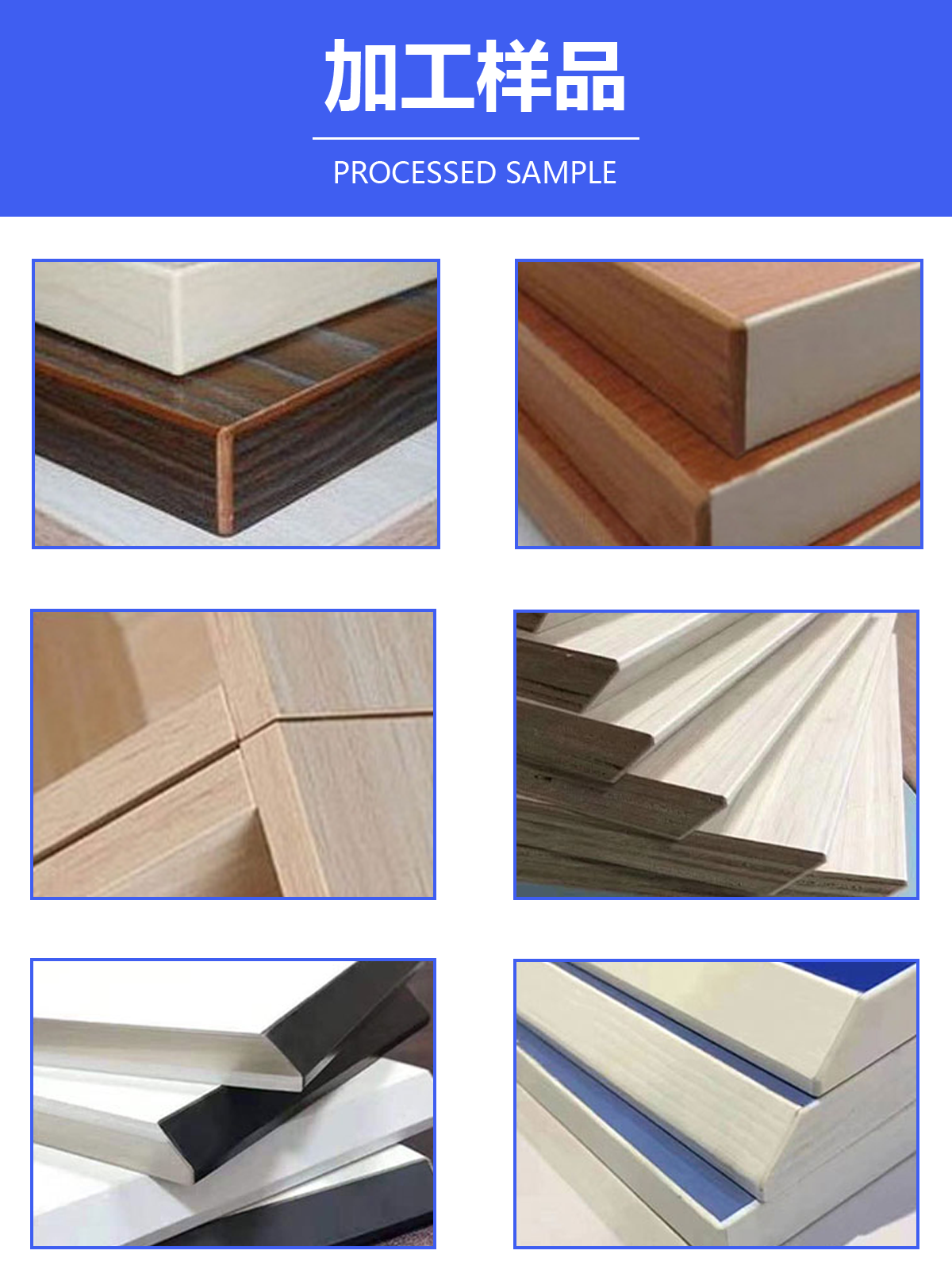

Multifunctionality: The fully automatic board edge banding machine has multiple functions such as single-sided trimming, double-sided trimming, chamfering, etc., to adapt to the edge banding needs of different boards. For example, it can achieve functions such as cutting double-sided adhesive edge banding, bonding and pressing edge banding, aligning, polishing, etc.

Stable and reliable: The equipment operates stably, reliably, and is durable, with a moderate price, suitable for manufacturers of large and medium-sized furniture, cabinets, and other panel furniture.

4、 Working principle

The working principle of a fully automatic sheet edge banding machine usually includes the following steps:

Cleaning treatment: Place the board to be treated in the working area of the machine, ensuring that the surface is free of dirt and impurities.

Measurement and positioning: The machine will automatically measure the size and shape of the board and position it to ensure the accuracy and precision of edge sealing.

Edge band preheating: The machine will preheat the edge band to an appropriate temperature through a heating device, in order to better bond with the surface of the board.

Edge tape bonding: The machine will bond the preheated edge tape to the edge of the board and ensure a tight bond between the edge tape and the surface of the board.

Cutting and trimming: After the edge tape is bonded, the machine will automatically cut off excess edge tape and trim the edges to make them smooth and even.

Testing and Inspection: The machine will automatically check whether the edge is secure and inspect the quality of the edge to ensure that each edge meets the requirements.

Completion and Collection: Finally, the machine will remove the processed boards from the work area and collect them for subsequent processing and production.

last page

next page

Related products