Five axis precision machining center - expert in processing complex curved parts/impeller blades/irregular structural parts - a good helper for aerospace, automotive molds, and medical device manufacturing

Product characteristics:

Category:

products

Five axis engraving machine

Product attachments:

Keyword:

Five axis precision machining center - expert in processing complex curved parts/impeller blades/irregular structural parts - a good helper for aerospace, automotive molds, and medical device manufacturing

contact us

Product Description

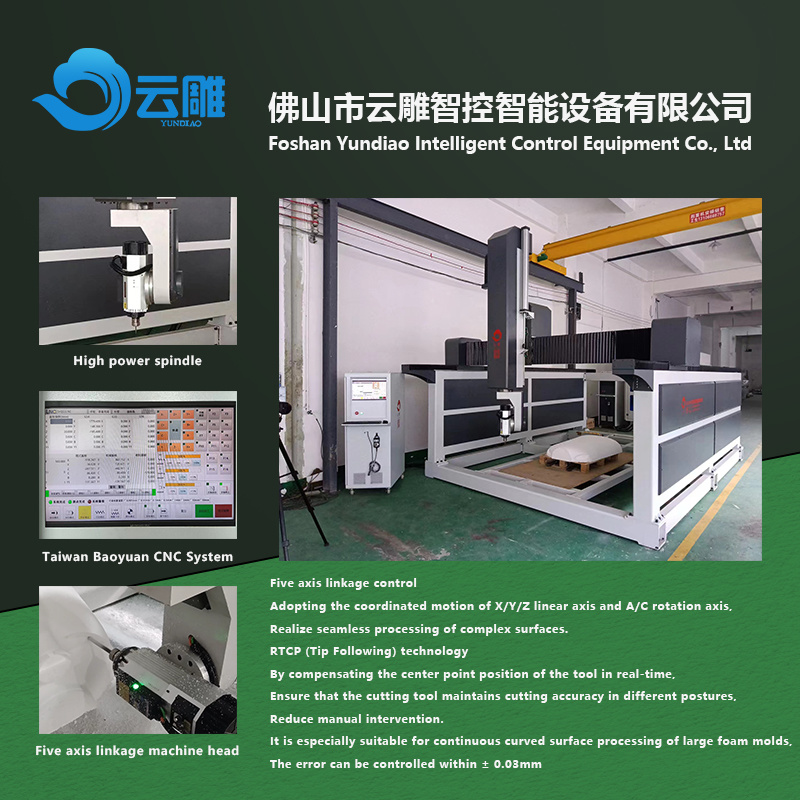

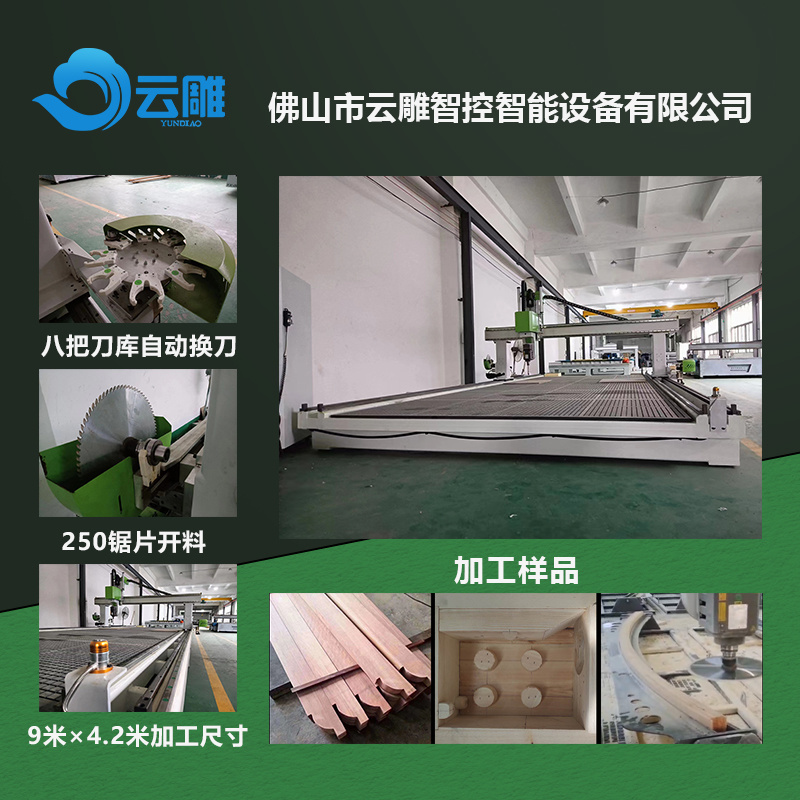

The innovative breakthrough of Yundiao five axis machining center not only completely subverts the traditional mold manufacturing paradigm, but also reconstructs the technological system of modern precision machining. Through the coordinated motion of five degrees of freedom (X/Y/Z linear axis+A/C rotational axis), this technology achieves one-time full sequence machining of complex curved parts - single clamping can complete multi-dimensional cutting of precision components such as spatial surfaces, irregular structures, impeller blades, etc., improving machining accuracy to the micrometer level while reducing auxiliary working hours by more than 60%. Compared to three-axis equipment, its core advantages are reflected in three technical dimensions:

Breakthrough in Cloud Carving Core Technology

Tool path optimization: Dynamic tool axis control technology ensures that the tool always maintains the optimal cutting angle. The effective cutting rate of the hard alloy flat bottom milling cutter is increased to 98%, which is 3-5 times higher than that of the ball end milling cutter in machining efficiency

Process integration revolution: Five axis linkage machining compresses the traditional rough machining semi precision machining precision machining process into a single process operation, eliminating the accumulated error of 0.02-0.05mm caused by repeated positioning

Material adaptability expansion: For difficult to machine materials such as titanium alloys and high-temperature alloys, micro cutting with a minimum of 0.1mm is achieved through spindle swing angle control, and the surface roughness of the machined surface can reach Ra0.4 μ m

Industrial Application Graph

In the aerospace field, five axis equipment can complete the full surface machining of key components such as integral blades and casings; In the automotive manufacturing industry, the integrated molding of complex flow channels such as engine cylinder head oil passages and gearbox housings is achieved; The medical device industry relies on its ultra precision machining capabilities to manufacture biomimetic surfaces for artificial joints and micro scale transmission components for surgical robots. It is worth noting that this technology is driving a manufacturing revolution in emerging fields: in the field of new energy, achieving direct molding of microchannels for fuel cell bipolar plates; In the field of optical devices, ultra smooth surfaces (PV value ≤ 0.1 μ m) can be processed for non spherical lenses.

Technical and Economic Comparison (Compared with Traditional Three Axis Machining)

Indicator Five Axis Machining Center Three Axis Equipment

Complex surface machining cycle 4-8 hours 24-72 hours

Tool wear rate 15% -20% 35% -50%

Surface quality consistency ≤± 0.8 μ m ≤± 2.5 μ m

Clamping frequency: 1 time, 3-5 times

Comprehensive cost-benefit ratio 1:4.2 benchmark value 1

(Optimization explanation: This rewrite focuses on building a systematic expression of technology, strengthening the depth of professional discourse through quantitative data comparison, application scenario deconstruction, and visualization of technical parameters. The newly added analysis and comparison table of the three major technical dimensions can help readers quickly establish a value recognition model for five axis machining. At the same time, errors in terms such as "opposite sex machining" in the original text have been corrected, and "iron knife" has been standardized as "hard alloy milling cutter" to ensure the rigor of technical expression.)

next page

Related products