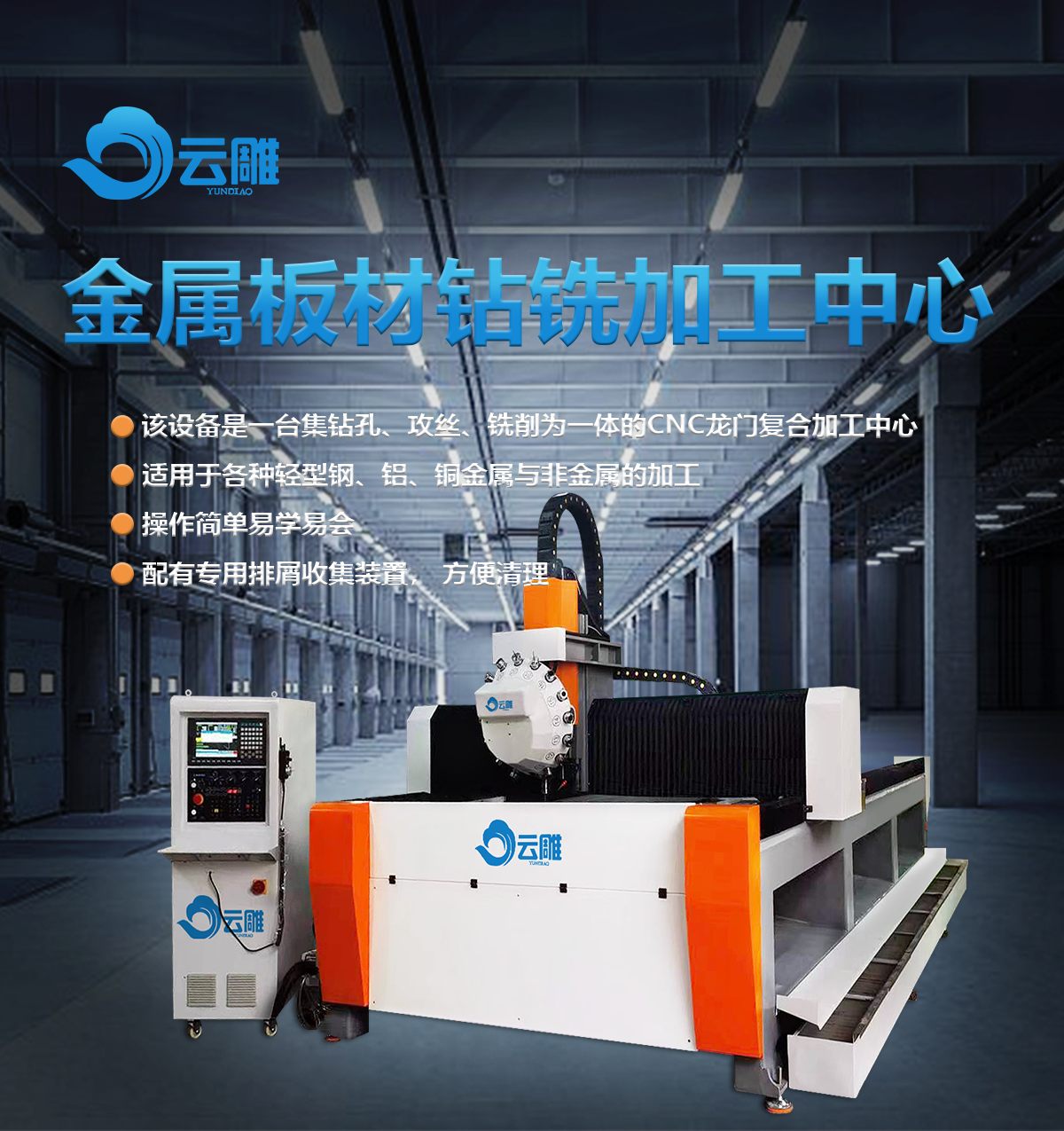

sheet metal working centre

Product characteristics:

Category:

products

Profile processing equipment

Product attachments:

Keyword:

sheet metal working centre

contact us

Product Description

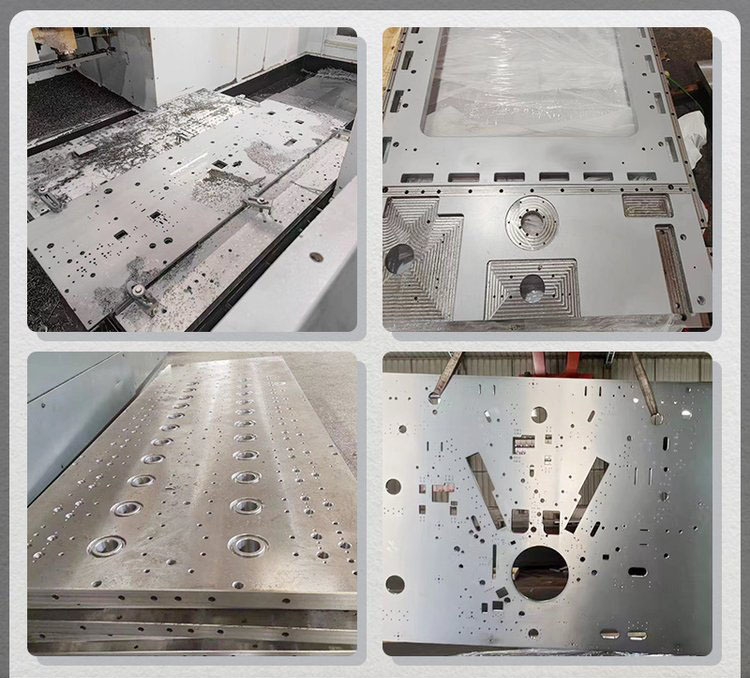

This is a CNC profile composite machining center that integrates drilling, tapping, milling, and chamfering. It uses an internationally specialized CNC system and is suitable for processing various lengths of steel, aluminum, copper metal, and non-metal. Adopting a rear protective sheet metal mode, it can prevent chips from flying around and is also equipped with an automatic chip removal machine for easy cleaning. The use of BT40 spindle taper hole increases the rigidity of the machine, resulting in high processing efficiency, accuracy, and strength.

Related applicable industries

Automobile manufacturing is used for precision stamping and forming of body sheet metal parts and chassis structural parts, supporting personalized customization needs.

Aerospace processing of lightweight and high-strength materials such as aircraft skins and engine components to meet the requirements of complex surface machining.

Architectural decoration involves the production of metal curtain walls, artistic forms, etc., and personalized design achieved through fine carving。

Parameter Description Weight: 10000kg, Main Motor Power: 11kw, Spindle Speed Range: 12000rpm Positioning Accuracy: 0.05, Tool Quantity: 24, Three Axis Travel (XYZ): 2500/550/500 Power Type: Pneumatic, Layout Form: Vertical

Related products