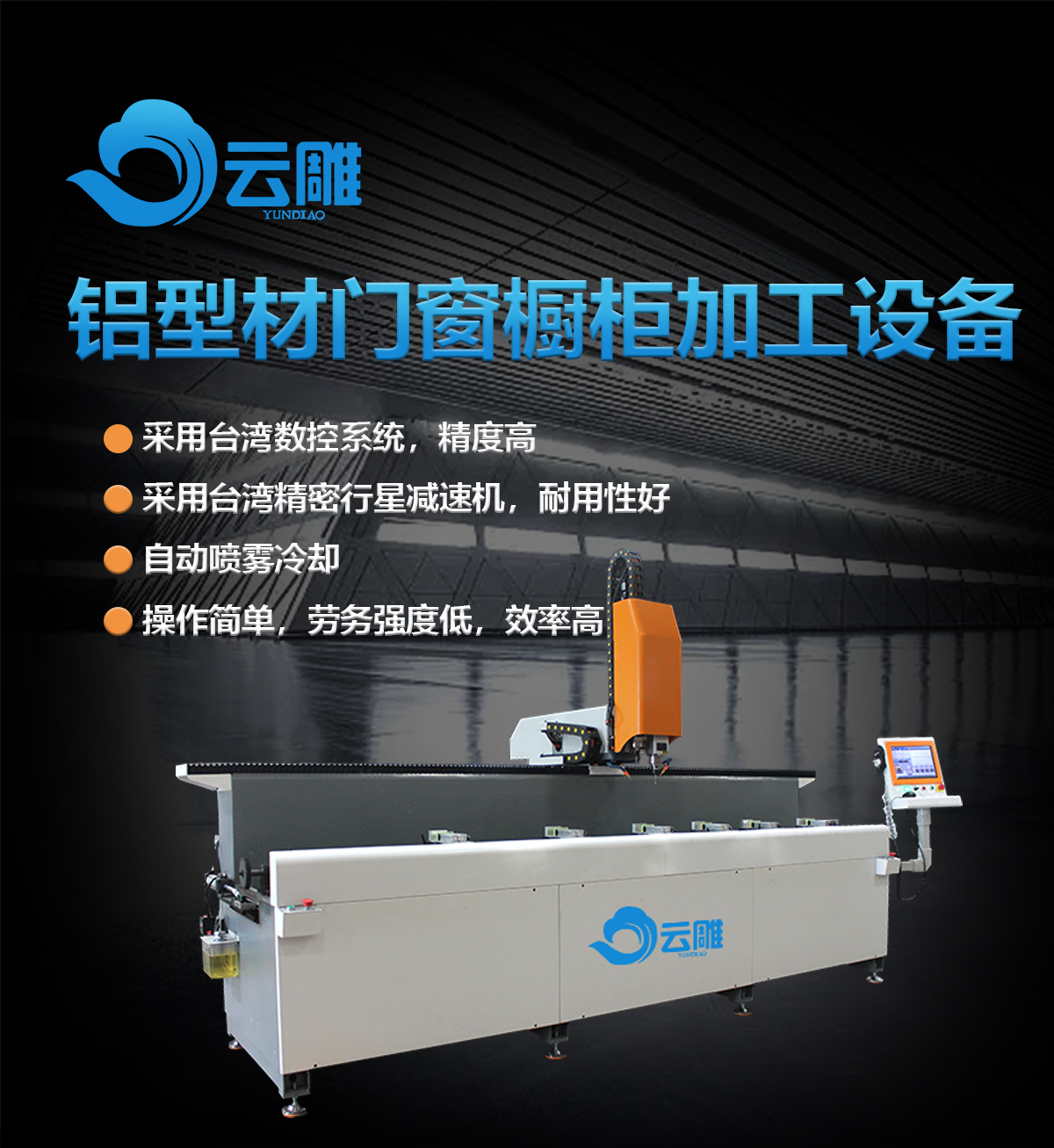

Aluminum profile drilling and milling machining center - optional eight tool magazine, doubling processing efficiency

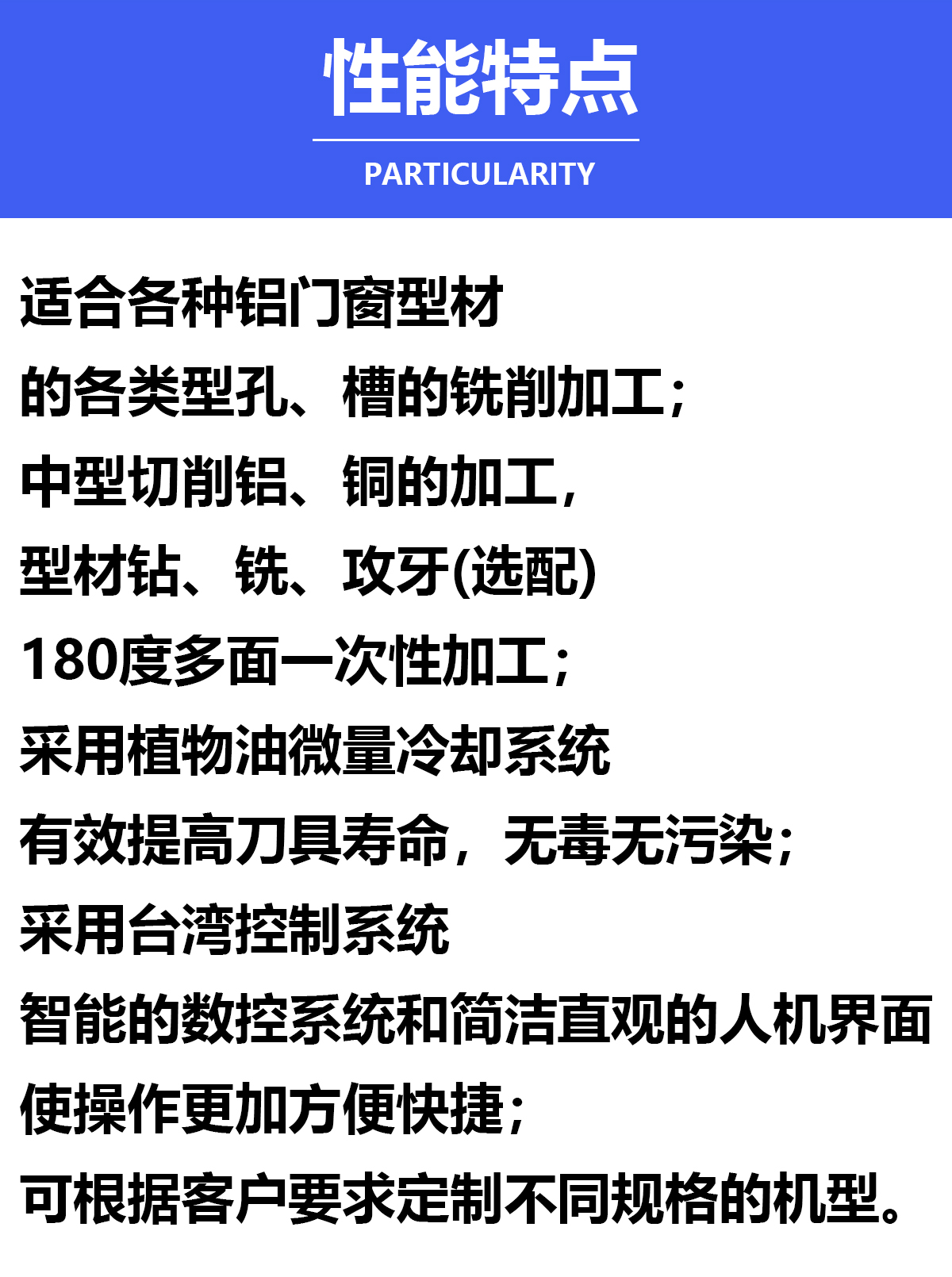

Product characteristics:

Multi functional integration

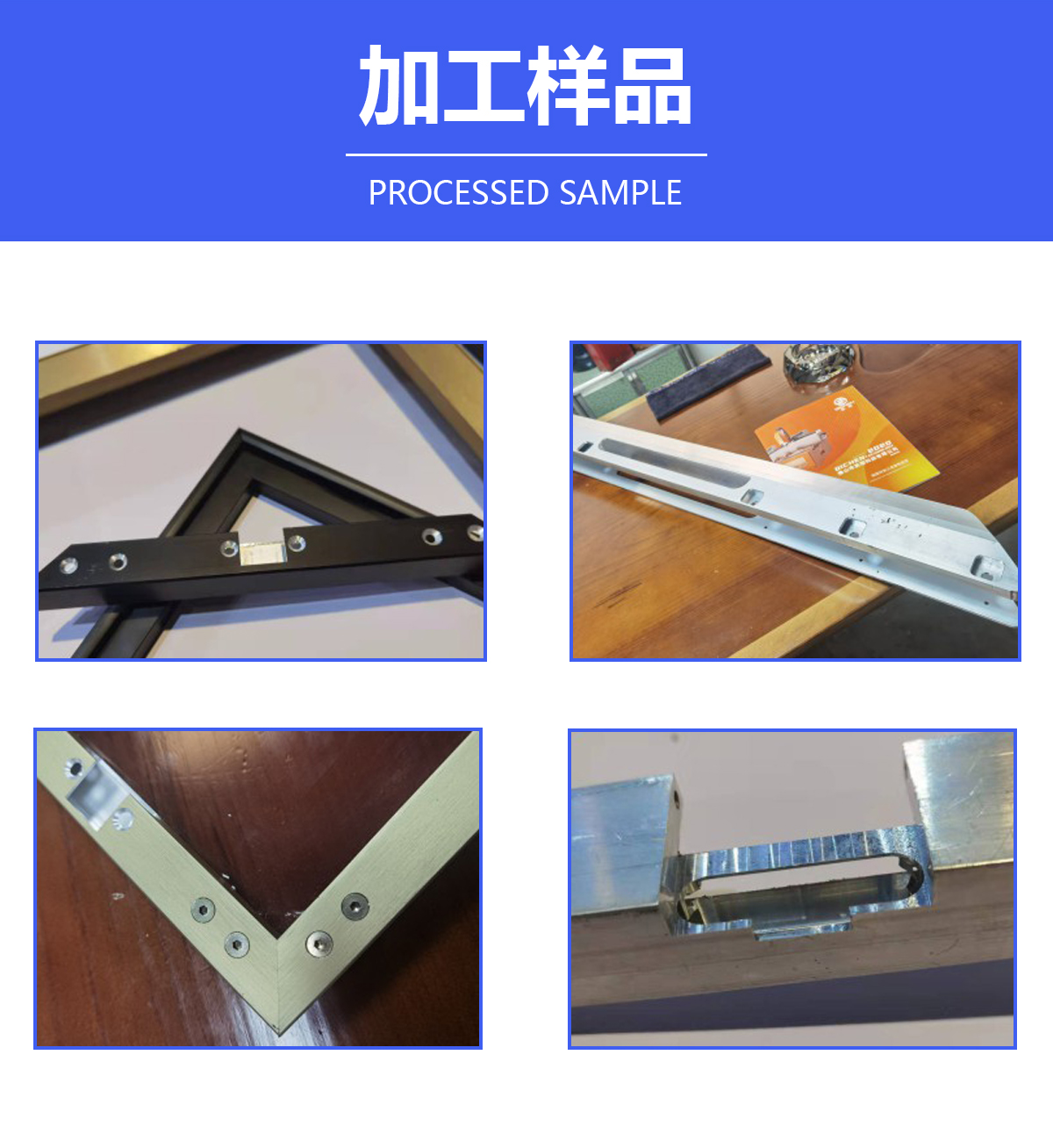

Supporting composite processing such as drilling, milling, tapping, cutting, carving, etc., multiple process operations can be completed at once to improve efficiency. Example: The skirt board of a rail transit vehicle needs to be drilled and milled simultaneously, and the machining center is achieved through multi axis linkage.

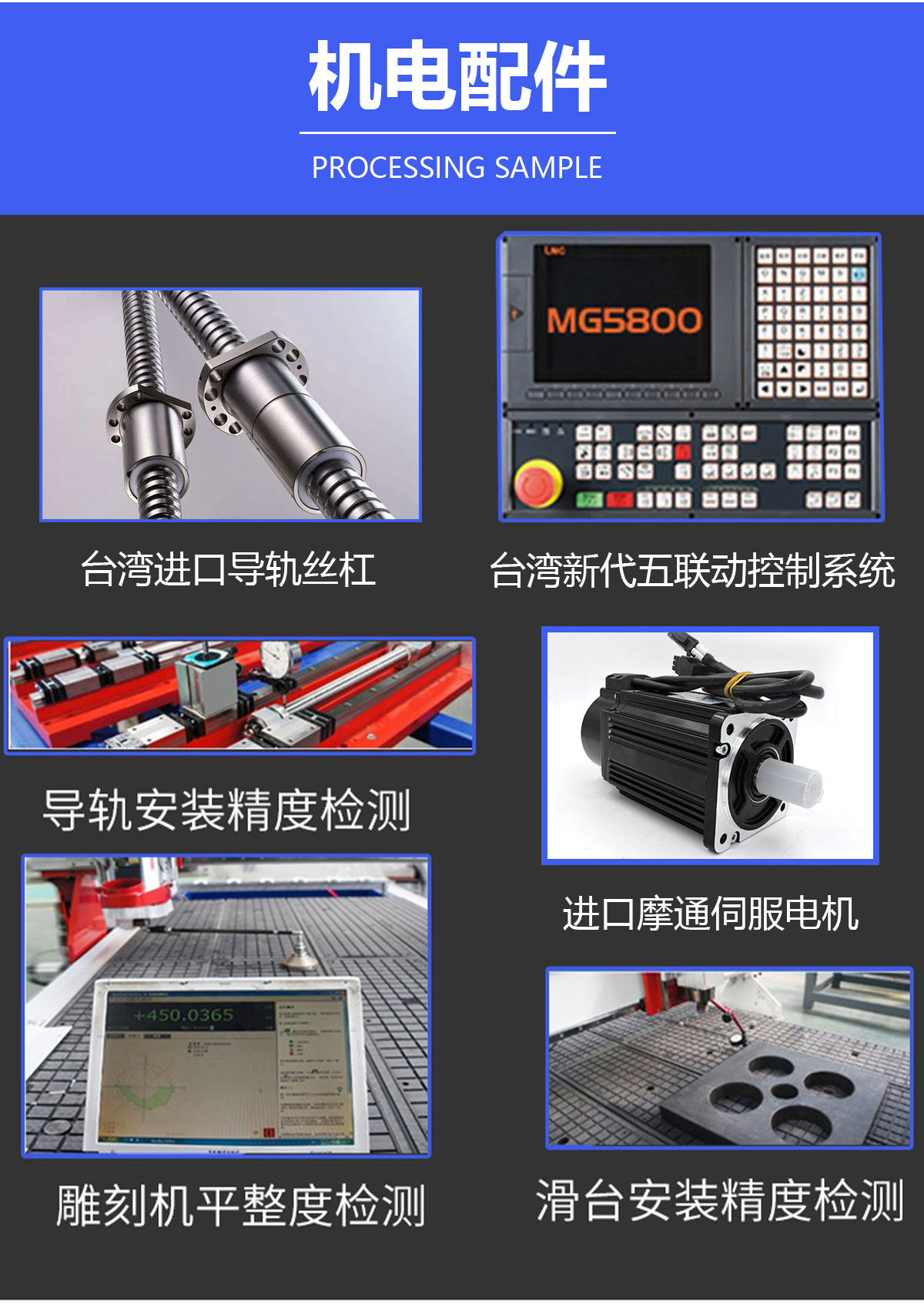

High precision and high-speed spindle speeds can reach 18000rpm (some models support 24000rpm), and imported electric spindles (such as HSD and ceramic bearings) are used to ensure stability.

Positioning accuracy ≤ 0.01mm, repeated positioning accuracy ≤ 0.005mm, meeting the requirements of precision parts (such as aluminum components for new energy vehicles).

Automatic and intelligent tool change system (8-24 station tool magazine), cooling spray/micro lubrication (MQL) system are equipped to reduce manual intervention.

Supporting new generation CNC systems, it can achieve programming path optimization and real-time monitoring.

Category:

products

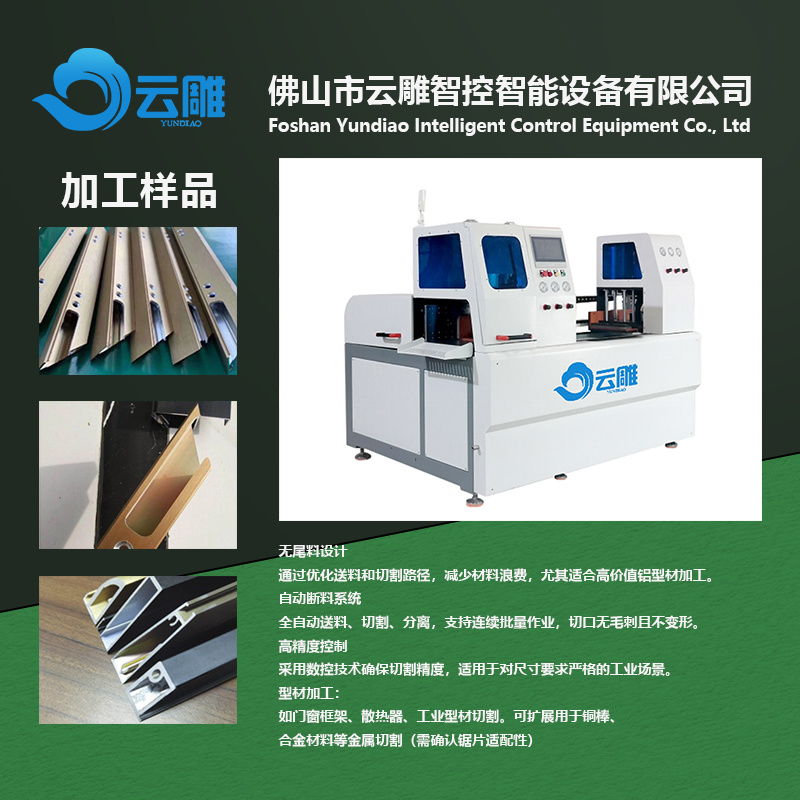

Profile processing equipment

Product attachments:

Keyword:

Aluminum profile drilling and milling machining center - optional eight tool magazine, doubling processing efficiency

contact us

Product Description

Related products