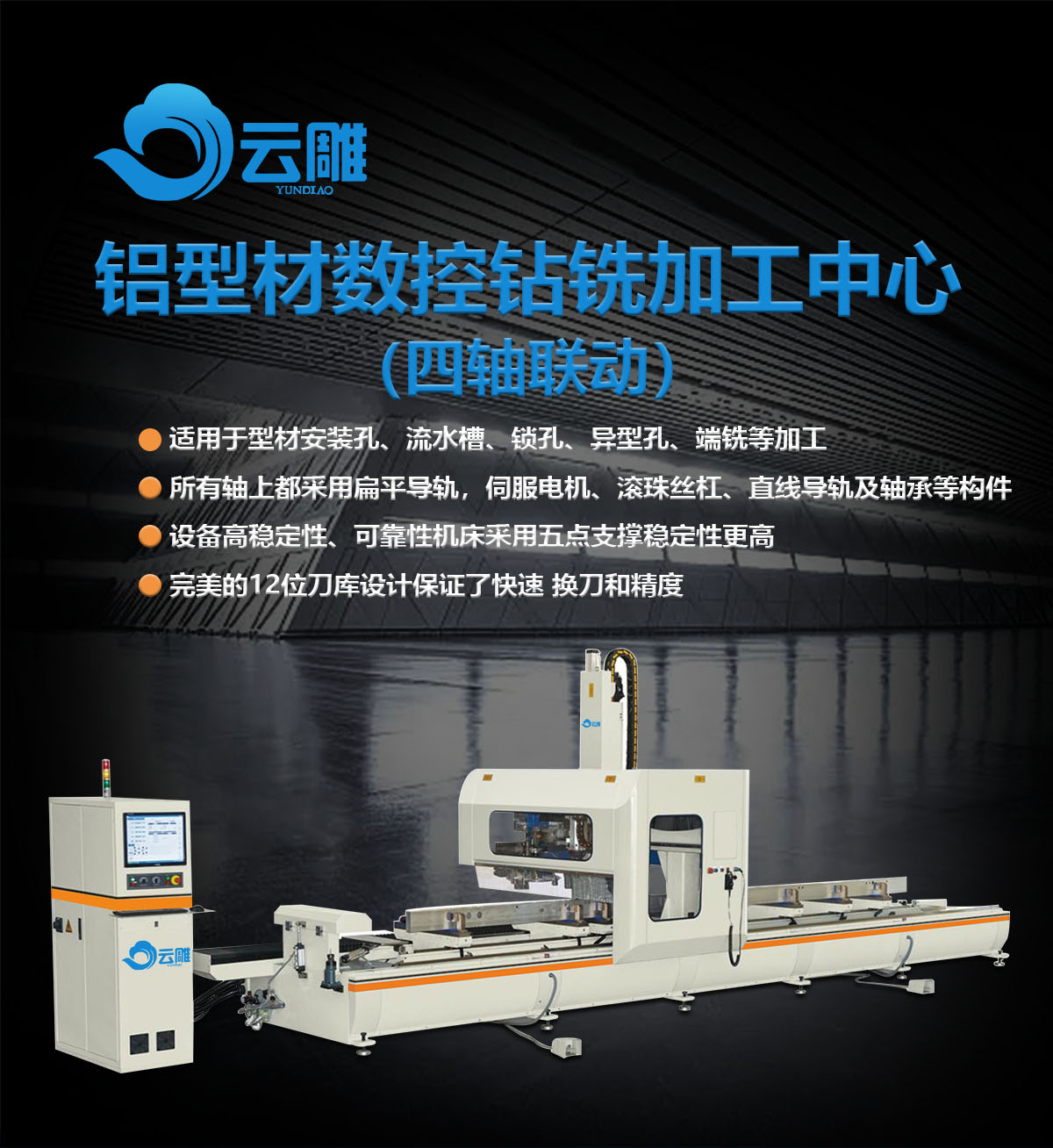

Aluminum profile CNC drilling and milling machining center (four axis linkage) - one-time clamping processing of complex surfaces and multi angle holes and grooves

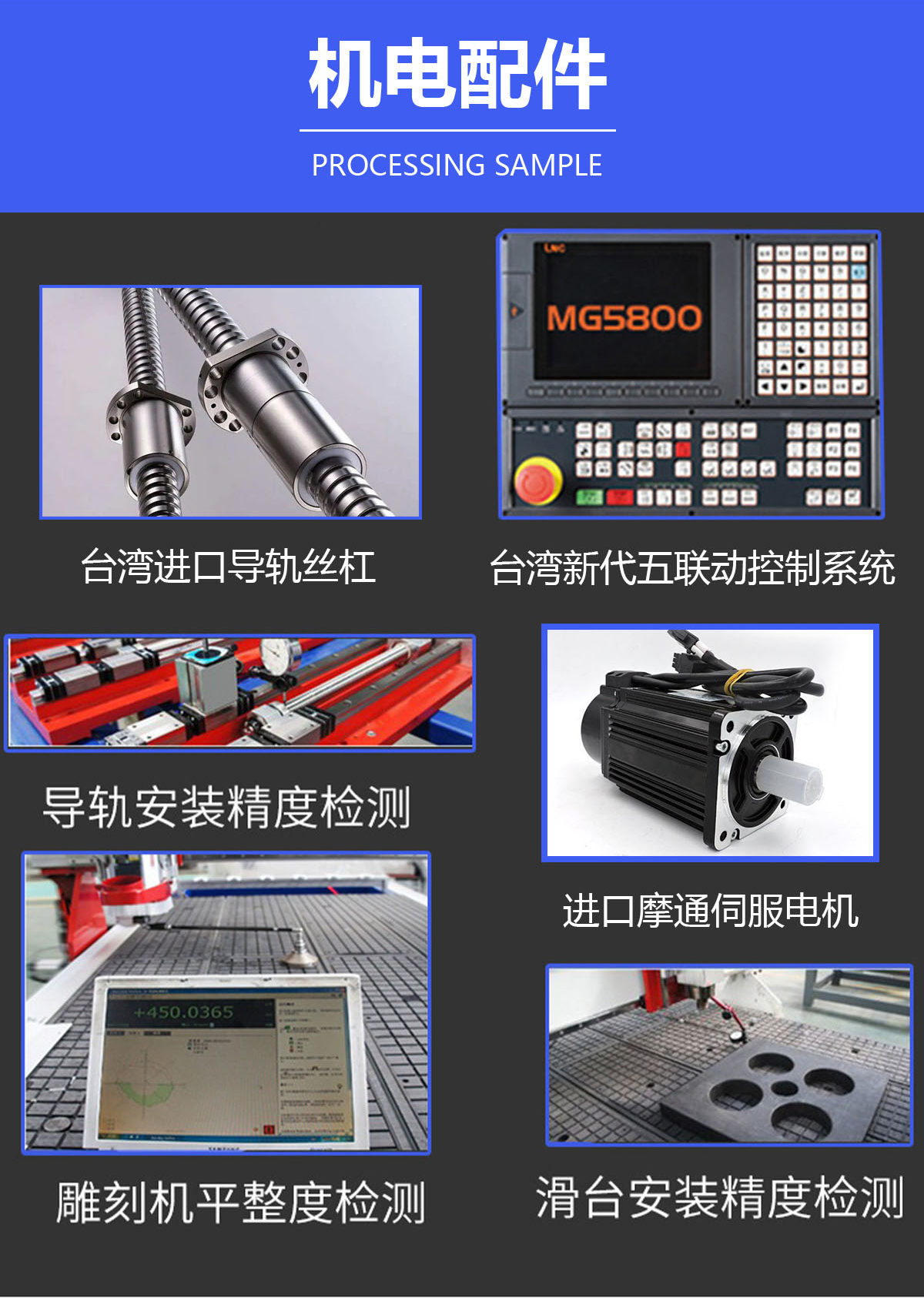

Product characteristics:

Efficient processing: By using servo flipping and multi axis linkage, the number of clamping times is reduced,

The typical processing efficiency is increased by more than 50%, for example, completing processes such as door and window lock holes and curtain wall slots in one go.

Complex process integration: supports composite processing such as drilling, milling, threading, and contour carving,

Especially suitable for processing irregular holes in aluminum profiles for rail transit and new energy vehicles.

Precision guarantee: equipped with spray cooling and automatic lubrication system to reduce thermal deformation and wear,

Ensure long-term processing stability.

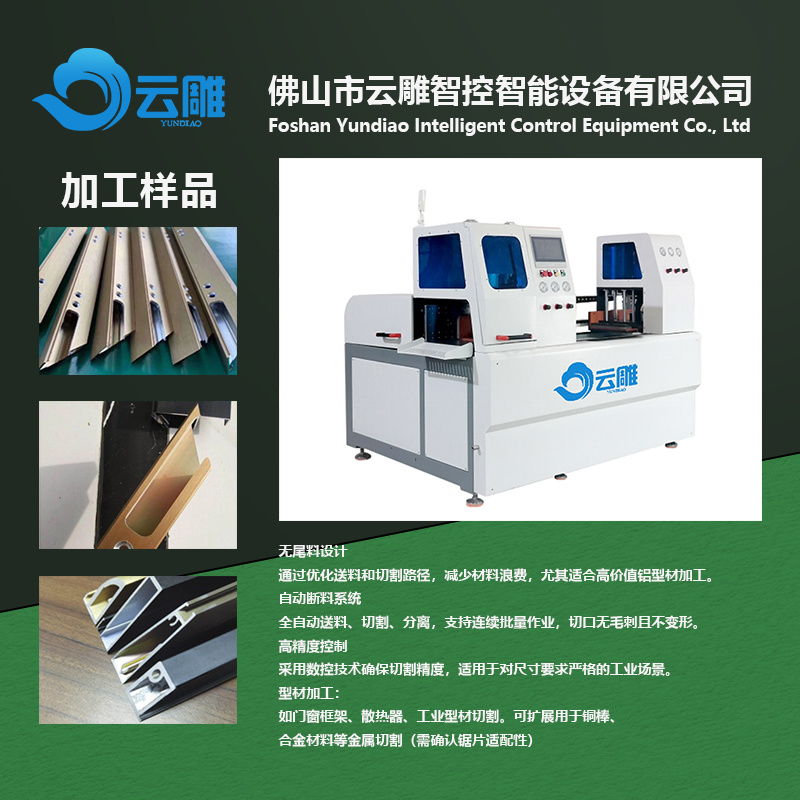

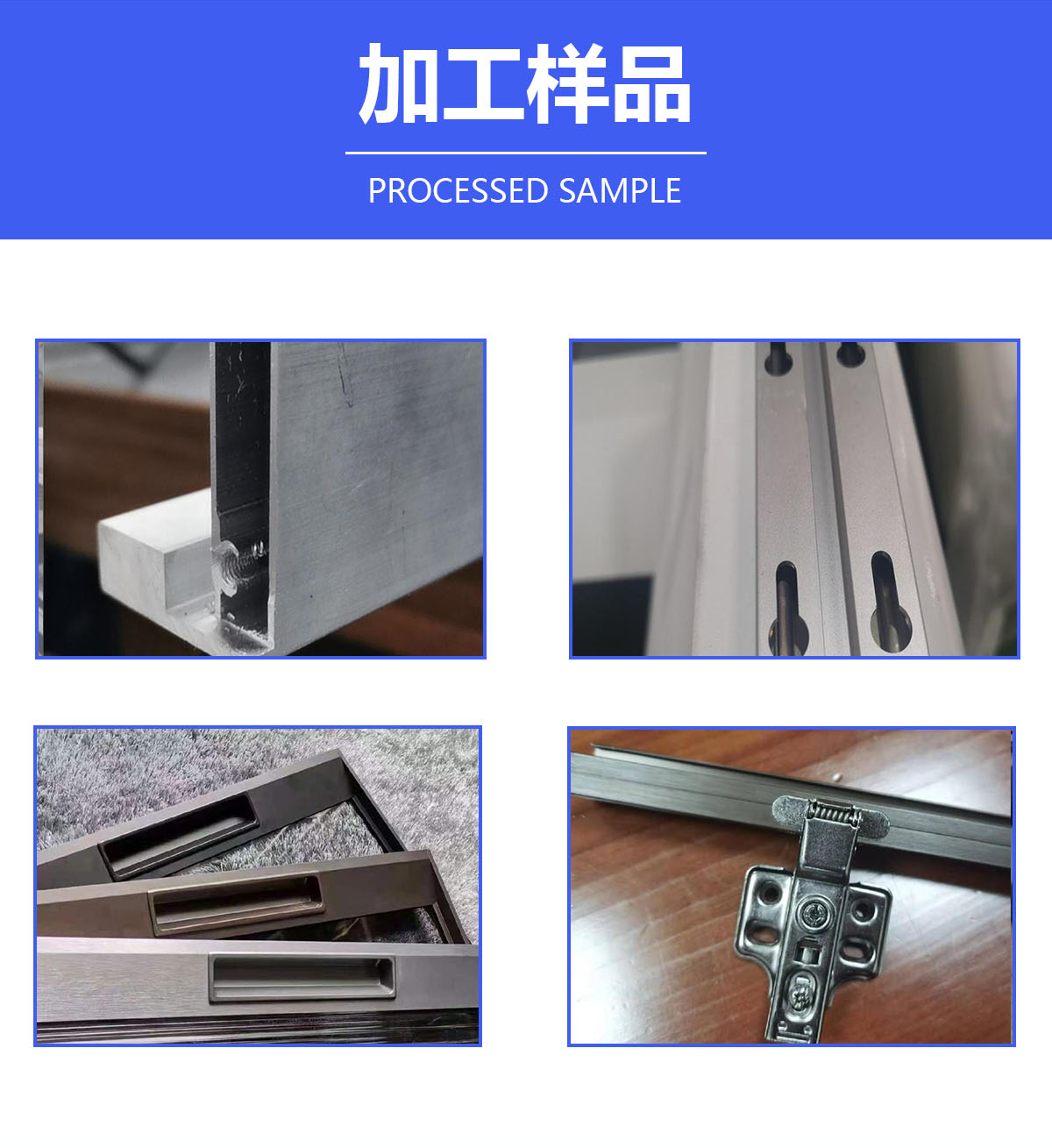

Industrial aluminum profiles: such as hole and groove processing for high-speed rail carriage frames and solar energy frames;

Doors, windows, and curtain walls: precision milling of extremely narrow edge cabinet doors and broken bridge aluminum doors and windows;

New energy vehicles: Multi sided drilling and milling integrated processing of battery pack brackets and anti-collision beams.

Category:

products

Profile processing equipment

Product attachments:

Keyword:

Aluminum profile CNC drilling and milling machining center (four axis linkage) - one-time clamping processing of complex surfaces and multi angle holes and grooves

contact us

Product Description

Related products