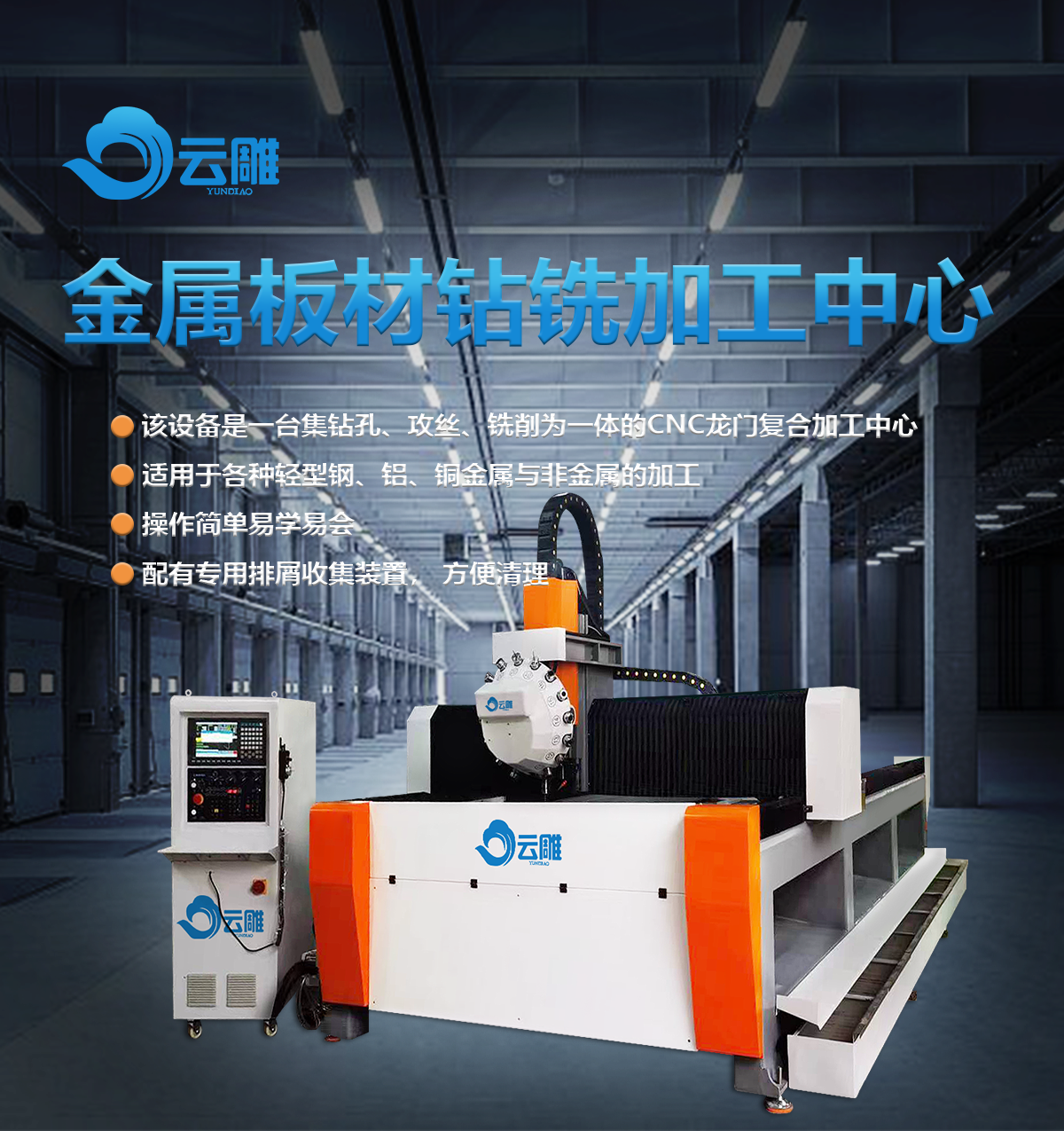

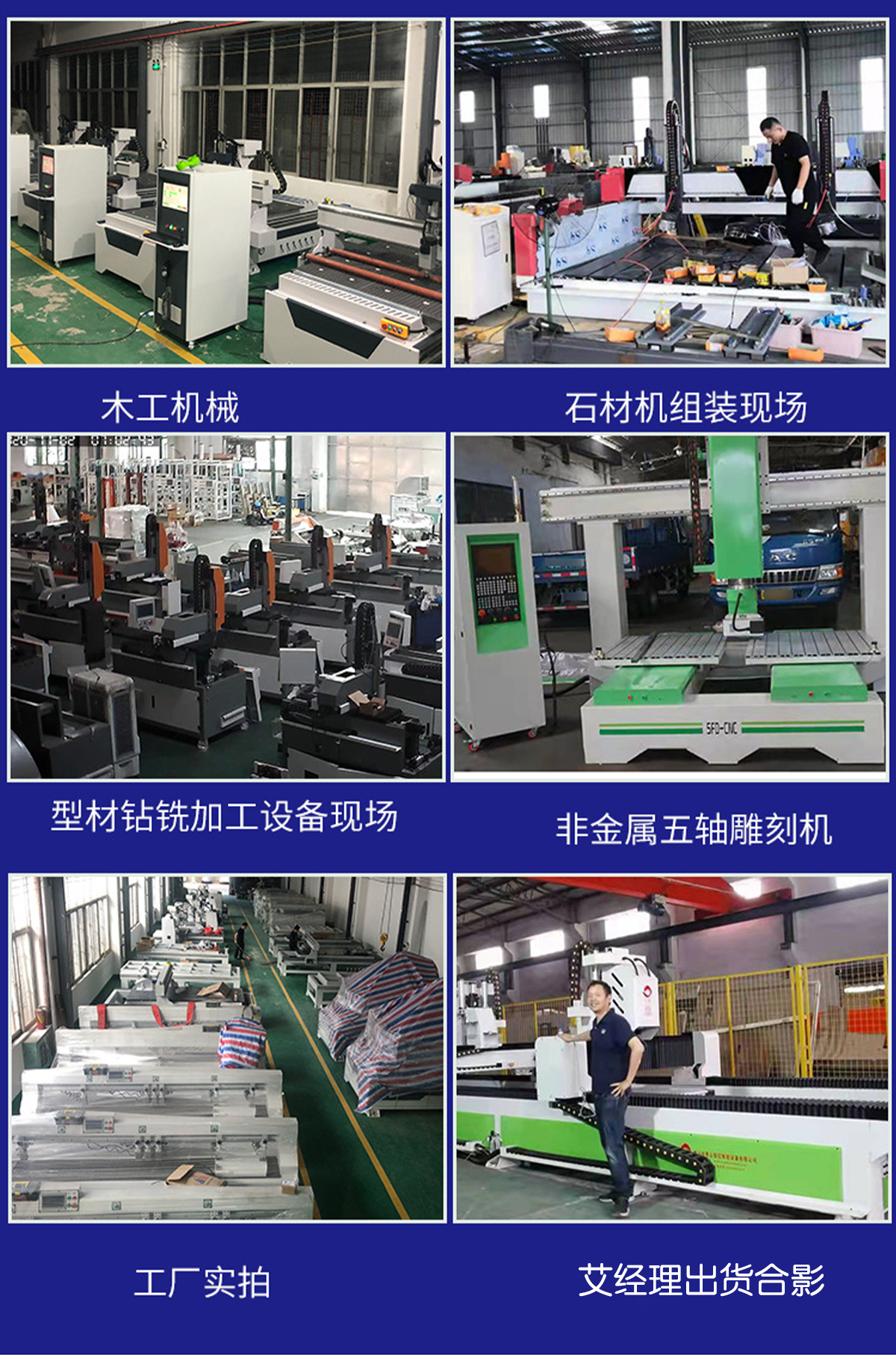

Sheet metal drilling and milling machining center

Sheet metal custom machining center is a high-efficiency, automated machine tool, mainly composed of mechanical equipment and numerical control system, used to process complex shapes of workpieces. It usually has a tool magazine, which can automatically change the tool and perform multi-process machining after the workpiece is clamped in one time. After the workpiece is clamped, the CNC system can control the machine tool to automatically select and replace the tool, automatically set the tool, automatically change the spindle speed, feed, etc., according to different processes, and can continuously complete a variety of processes such as drilling, boring, milling, reaming, tapping, etc

Product characteristics:

Category:

Profile processing equipment

Product attachments:

Keyword:

Sheet metal drilling and milling machining center

contact us

Product Description

|

order number |

Product model and specification |

Product technical parameters |

Product characteristics |

|

|

1 |

CNC-5200C6 aluminum profile CNC drilling and milling tapping center 650024002300 |

Transverse stroke (X-axis stroke) |

5200 |

Using four station processing, processing four workpieces, to achieve drilling attack, milling, groove, four groups of head can be changed at the same time, four groups of knife library freely switch the tool, complete the whole process at a time, the efficiency is twice the result with half the effort |

|

Longitudinal stroke (Y-axis stroke) |

500 |

|||

|

Vertical stroke (Z-axis stroke) |

300 |

|||

|

X axis operation speed |

0-50m/min |

|||

|

The Y / Z axis running speed |

0-30m/min |

|||

|

X axis servo |

0.85KW |

|||

|

Y axis servo |

0.85KW |

|||

|

Z axis servo |

0.85KW |

|||

|

Axis A servo |

0.85KW x2 |

|||

|

Intelligent avoidance servo clamp |

0.4KW x6 |

|||

|

Servo brand |

Huichuan |

|||

|

main shaft speed |

24000R/min |

|||

|

Spindle power |

9KW |

|||

|

Four independent nose |

Implement free switching |

|||

|

Knife clip head |

ISO32 |

|||

|

air supply |

0.6-0.8mpa |

|||

|

Spindle motor brand |

Dongguan day |

|||

|

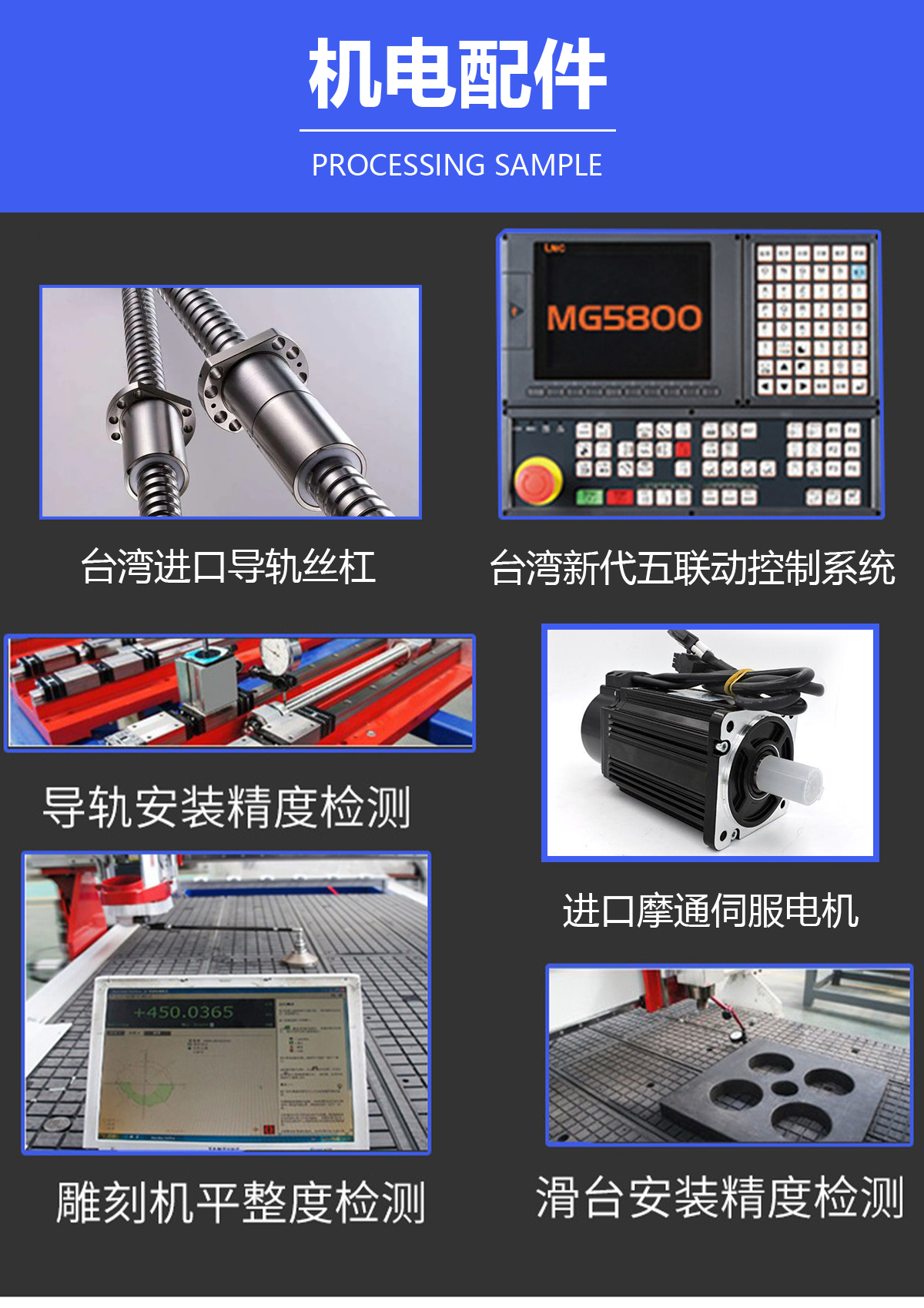

Guide rail wire rod brand |

Taiwan HIWIN on silver / Yintai |

|||

|

Reducer brand |

Faston, Taiwan |

|||

|

system |

Taiwan new generation system |

|||

|

Form and quantity of the knife library |

Mid-line library (6) |

|||

|

Main electrical components |

Huikawa, Schneider, and Omron |

|||

|

Main pneumatic accessories brand |

Yard guest |

|||

|

working power supply |

380V + zero line, three-phase 5 line 50 HZ |

|||

|

Total power of the machine |

16KW |

|||

|

Automatic to knife instrument |

equip |

|||

|

lube oil system |

Automatic oil pump lubrication |

|||

|

Knife cooling method |

Automatic spray cooling |

|||

|

Processing range (width, height and length) |

250×150×5200 |

|||

|

total weight |

≈3500KG |

|||

|

Main shape size |

6500×2400×2300 |

|||

Related products