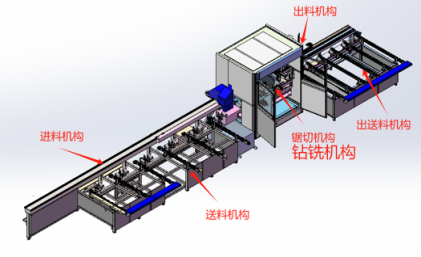

Industrial aluminum profile drilling, tapping and milling machine - servo flipping is more efficient

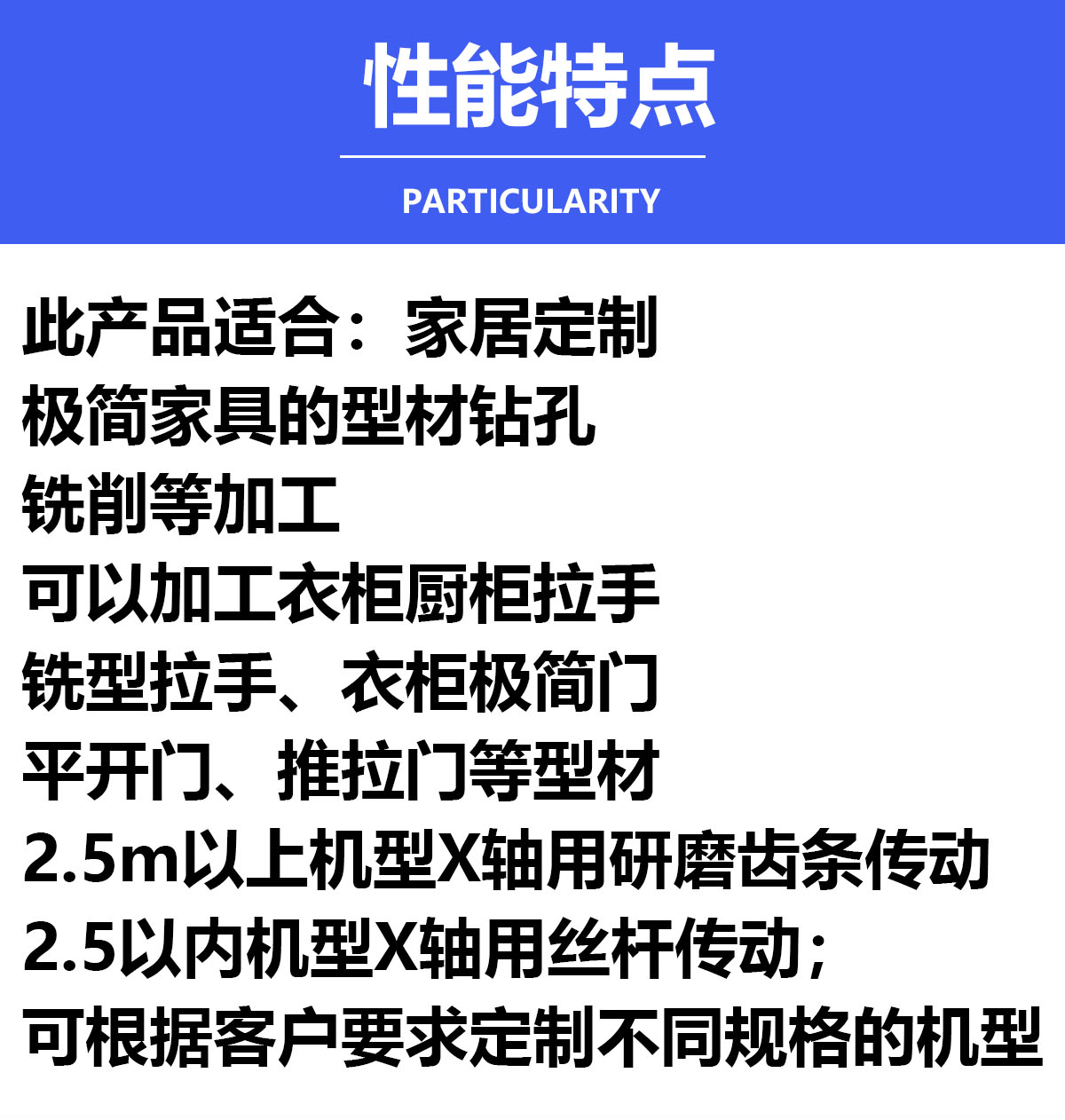

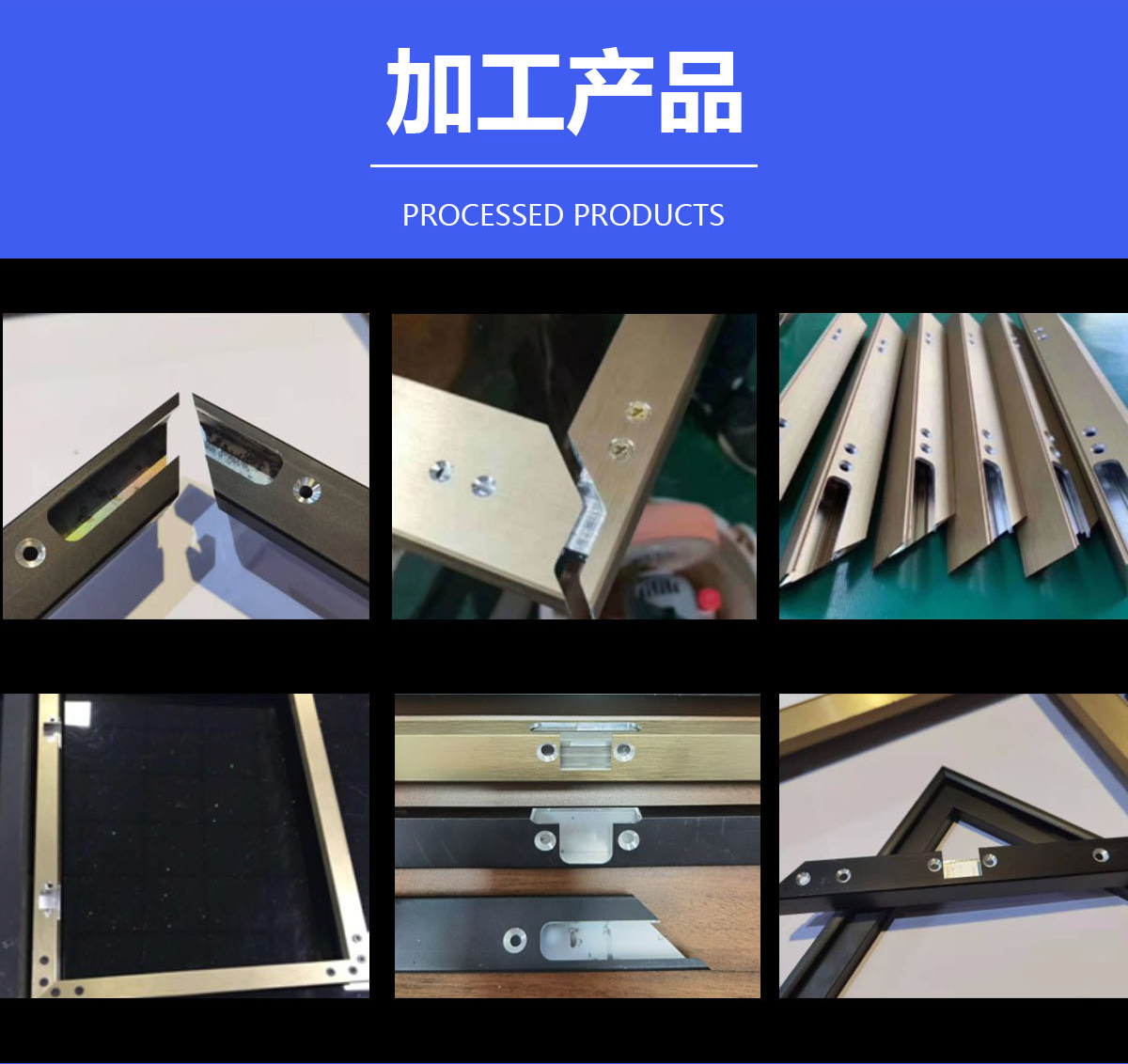

This product is suitable for: home customization, minimalist furniture profiles, drilling, milling and other processing, can process wardrobes, kitchen cabinets, handles, milling handles, wardrobes, minimalist doors, swing doors, sliding doors and other profiles, models above 2.5m, models with grinding rack transmission for X-axis, and screw drive for models within 2.5 models; Models with different specifications can be customized according to customer requirements

Product characteristics:

Category:

Profile processing equipment

Product attachments:

Keyword:

Industrial aluminum profile drilling, tapping and milling machine - servo flipping is more efficient

contact us

Product Description

|

一、云雕CNC3500散热器切钻一体机 |

|

||||||

|

|

|

||||||

|

性能特点: 1.专业用于铝型材的切割。

|

|

||||||

|

1.1、主要零部件使用品牌及规格 |

|

||||||

|

序号 |

零部件名称 |

品牌 |

品牌属地 |

备注 |

|

||

|

1 |

控制器系统 |

大族 |

中国 |

|

|

||

|

2 |

主轴单元 |

天洋 |

意大利 |

|

|

||

|

3 |

丝杆 |

TBI |

中国台湾 |

|

|

||

|

4 |

伺服单元 |

汇川 |

中国 |

总线绝对值 |

|

||

|

5 |

滚珠导轨 |

上银 |

中国台湾 |

|

|

||

|

6 |

齿轮齿条 |

法斯顿 |

中国台湾 |

|

|

||

|

7 |

减速机 |

法斯顿 |

中国台湾 |

|

|

||

|

8 |

气动元件 |

亚德客 |

中国台湾 |

|

|

||

|

9 |

电揽 |

旋邦 |

中国 |

|

|

||

|

10 |

拖链系统 |

其琛 |

中国 |

|

|

||

|

11 |

电气元件 |

欧姆龙/施耐德 |

日本/德国 |

|

|

||

|

12 |

总电源开关 |

欧姆龙/施耐德 |

日本/德国 |

|

|

||

|

13 |

润滑系统 |

宝腾 |

中国 |

|

|

||

|

备注: 以上是机床主要零件的供应商.我司因技术改造需更换厂商零件. 但更换后的零件品质不低于原零件的质量等级。 |

|

||||||

|

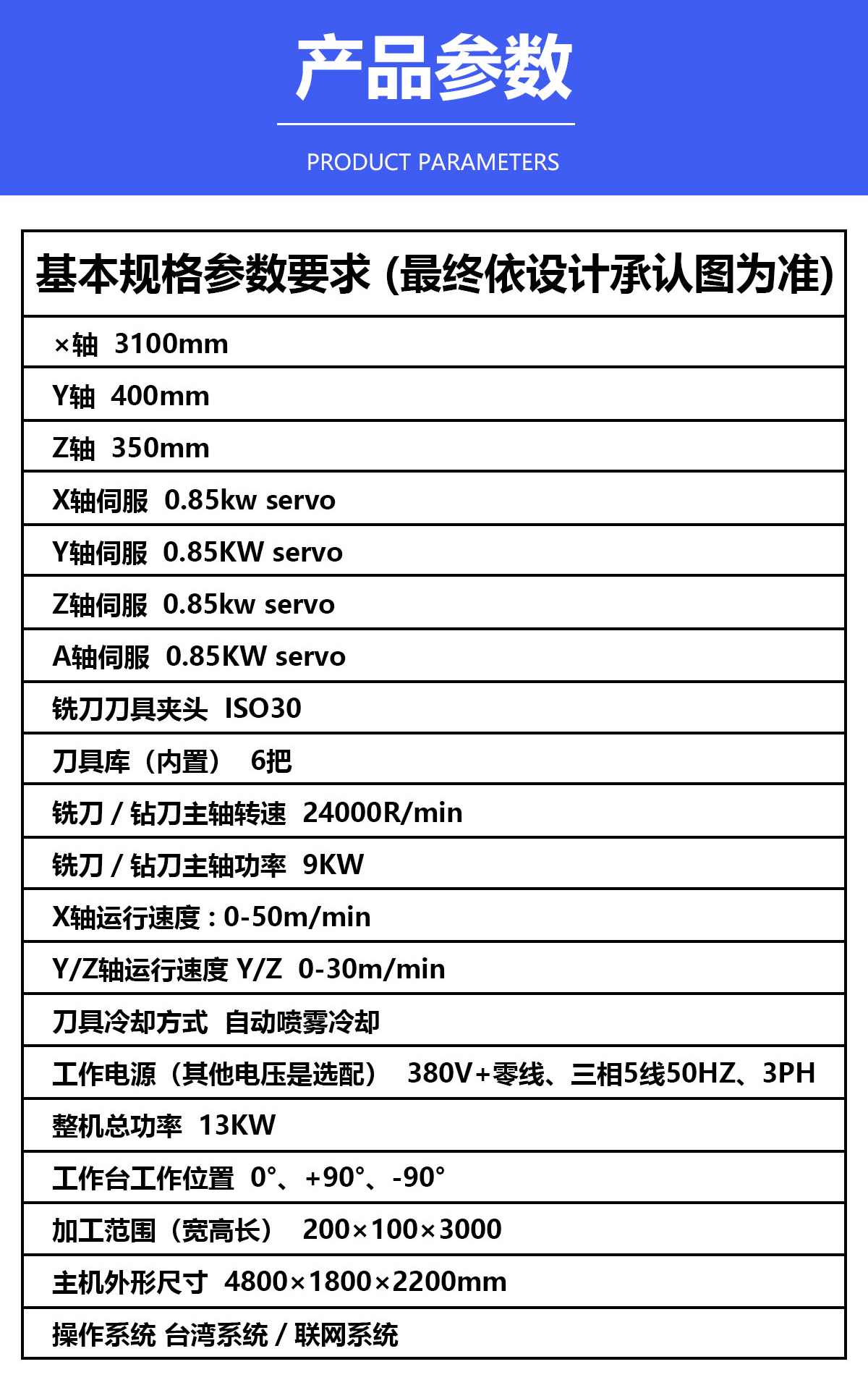

1.2、技术规格参数表 |

|

||||||

|

|

单位 |

参数 |

|

||||

|

加工 |

|

mm |

300-3500 |

|

|||

|

宽度 |

mm |

150 |

|

||||

|

|

mm |

150 |

|

||||

|

角度 |

mm |

90° |

|

||||

|

钻铣主轴 |

|

KW |

3.5KW |

|

|||

|

最高转速 |

rpm |

2800 |

|

||||

|

冷却 |

|

风冷 |

|

||||

|

安装方式 |

|

立式 |

|

||||

|

传动方式 |

|

电主轴 |

|

||||

|

锯切主轴 |

功率 |

KW |

5.5KW*2 |

|

|||

|

最高转速 |

rpm |

2800 |

|

||||

|

冷却 |

|

风冷 |

|

||||

|

安装方式 |

|

立式 |

|

||||

|

传动方式 |

|

电主轴 |

|

||||

|

加工精度 |

切割精度 |

mm |

±0.10 |

|

|||

|

切割型面平面度 |

mm |

≤0.10mm |

|

||||

|

润滑 |

丝杆润滑 |

|

自动油脂润滑装置 |

|

|||

|

导轨润滑 |

|

自动油脂润滑装置 |

|

||||

|

|

切削液箱容量 |

L |

12 |

|

|||

|

|

|

水循环切削冷却系统 |

|

||||

|

总功率 |

|

KW |

30.5 |

|

|||

|

除屑方式 |

输送式 |

|

链钣排屑机 |

|

|||

|

护罩设备 |

机床防护 |

|

封闭式防护钣金罩 |

|

|||

|

导轨防护 |

|

X轴风琴式导轨防护 |

|

||||

|

机床运行环境 |

电源 |

|

380 V 50Hz |

|

|||

|

气源 |

耗气量 |

L/min |

60 |

|

|||

|

工作压力 |

Mpa |

0.6Mpa-0.8Mpa |

|

||||

|

接地电阻 |

|

小于 10 欧姆(单独接地,不串联接地) |

|

||||

|

机床尺寸 |

机床长宽高 |

mm |

6100*1700*1650 |

|

|||

|

整机重量 |

kg |

≈5000 |

|

||||

|

一、云雕CNC3500散热器切钻一体机 |

|

||||||

|

|

|

||||||

|

性能特点: 1.专业用于铝型材的切割。

|

|

||||||

|

1.1、主要零部件使用品牌及规格 |

|

||||||

|

序号 |

零部件名称 |

品牌 |

品牌属地 |

备注 |

|

||

|

1 |

控制器系统 |

大族 |

中国 |

|

|

||

|

2 |

主轴单元 |

天洋 |

意大利 |

|

|

||

|

3 |

丝杆 |

TBI |

中国台湾 |

|

|

||

|

4 |

伺服单元 |

汇川 |

中国 |

总线绝对值 |

|

||

|

5 |

滚珠导轨 |

上银 |

中国台湾 |

|

|

||

|

6 |

齿轮齿条 |

法斯顿 |

中国台湾 |

|

|

||

|

7 |

减速机 |

法斯顿 |

中国台湾 |

|

|

||

|

8 |

气动元件 |

亚德客 |

中国台湾 |

|

|

||

|

9 |

电揽 |

旋邦 |

中国 |

|

|

||

|

10 |

拖链系统 |

其琛 |

中国 |

|

|

||

|

11 |

电气元件 |

欧姆龙/施耐德 |

日本/德国 |

|

|

||

|

12 |

总电源开关 |

欧姆龙/施耐德 |

日本/德国 |

|

|

||

|

13 |

润滑系统 |

宝腾 |

中国 |

|

|

||

|

备注: 以上是机床主要零件的供应商.我司因技术改造需更换厂商零件. 但更换后的零件品质不低于原零件的质量等级。 |

|

||||||

|

1.2、技术规格参数表 |

|

||||||

|

名称 |

单位 |

参数 |

|

||||

|

加工 |

长度 |

mm |

300-3500 |

|

|||

|

宽度 |

mm |

150 |

|

||||

|

高度 |

mm |

150 |

|

||||

|

角度 |

mm |

90° |

|

||||

|

钻铣主轴 |

功率 |

KW |

3.5KW |

|

|||

|

最高转速 |

rpm |

2800 |

|

||||

|

冷却 |

|

风冷 |

|

||||

|

安装方式 |

|

立式 |

|

||||

|

传动方式 |

|

电主轴 |

|

||||

|

锯切主轴 |

功率 |

KW |

5.5KW*2 |

|

|||

|

最高转速 |

rpm |

2800 |

|

||||

|

冷却 |

|

风冷 |

|

||||

|

安装方式 |

|

立式 |

|

||||

|

传动方式 |

|

电主轴 |

|

||||

|

加工精度 |

切割精度 |

mm |

±0.10 |

|

|||

|

切割型面平面度 |

mm |

≤0.10mm |

|

||||

|

润滑 |

丝杆润滑 |

|

自动油脂润滑装置 |

|

|||

|

导轨润滑 |

|

自动油脂润滑装置 |

|

||||

|

冷却 |

切削液箱容量 |

L |

12 |

|

|||

|

切削冷却 |

|

水循环切削冷却系统 |

|

||||

|

总功率 |

|

KW |

30.5 |

|

|||

|

除屑方式 |

输送式 |

|

链钣排屑机 |

|

|||

|

护罩设备 |

机床防护 |

|

封闭式防护钣金罩 |

|

|||

|

导轨防护 |

|

X轴风琴式导轨防护 |

|

||||

|

机床运行环境 |

电源 |

|

380 V 50Hz |

|

|||

|

气源 |

耗气量 |

L/min |

60 |

|

|||

|

工作压力 |

Mpa |

0.6Mpa-0.8Mpa |

|

||||

|

接地电阻 |

|

小于 10 欧姆(单独接地,不串联接地) |

|

||||

|

机床尺寸 |

机床长宽高 |

mm |

6100*1700*1650 |

|

|||

|

整机重量 |

kg |

≈5000 |

|

||||

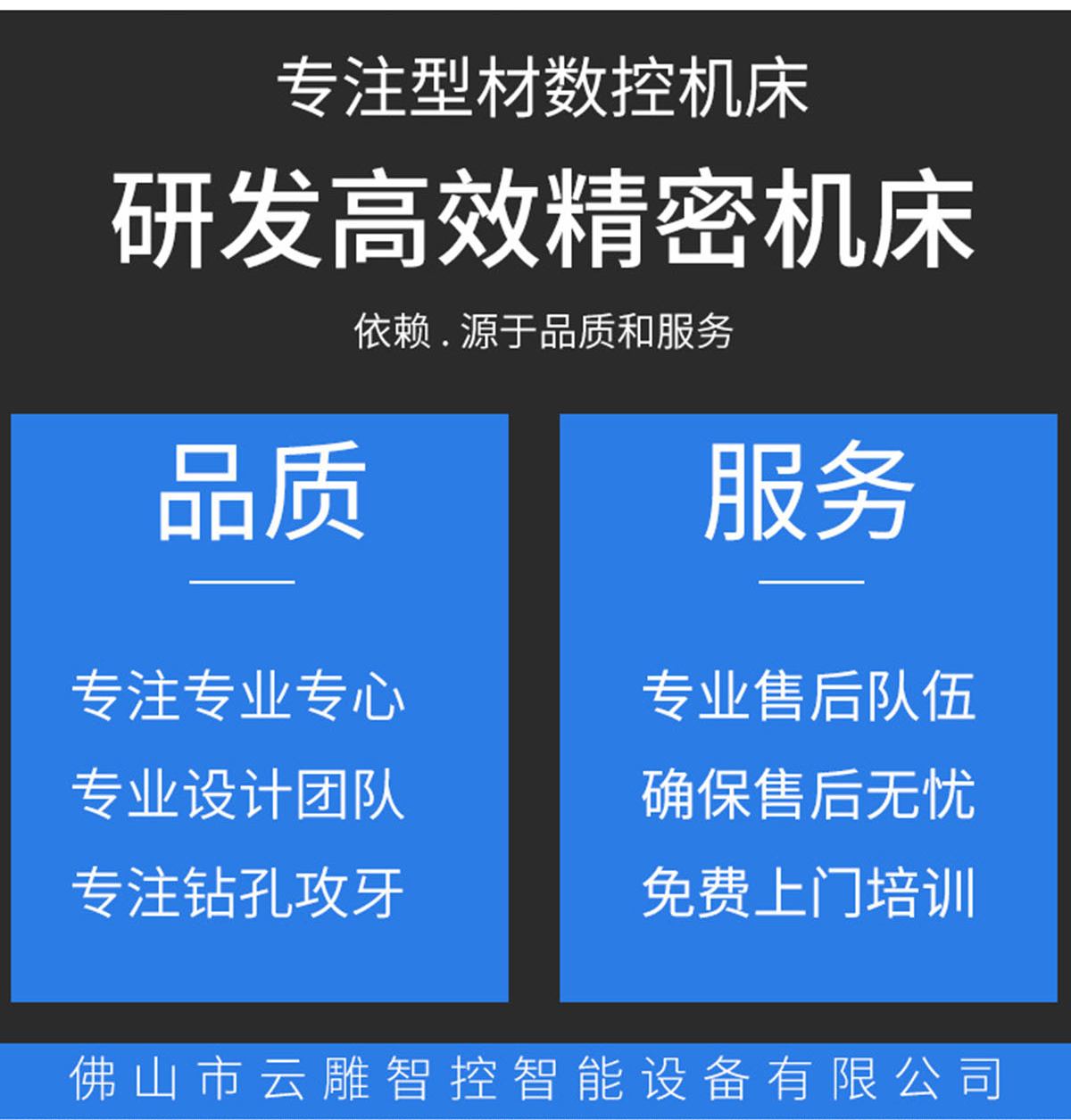

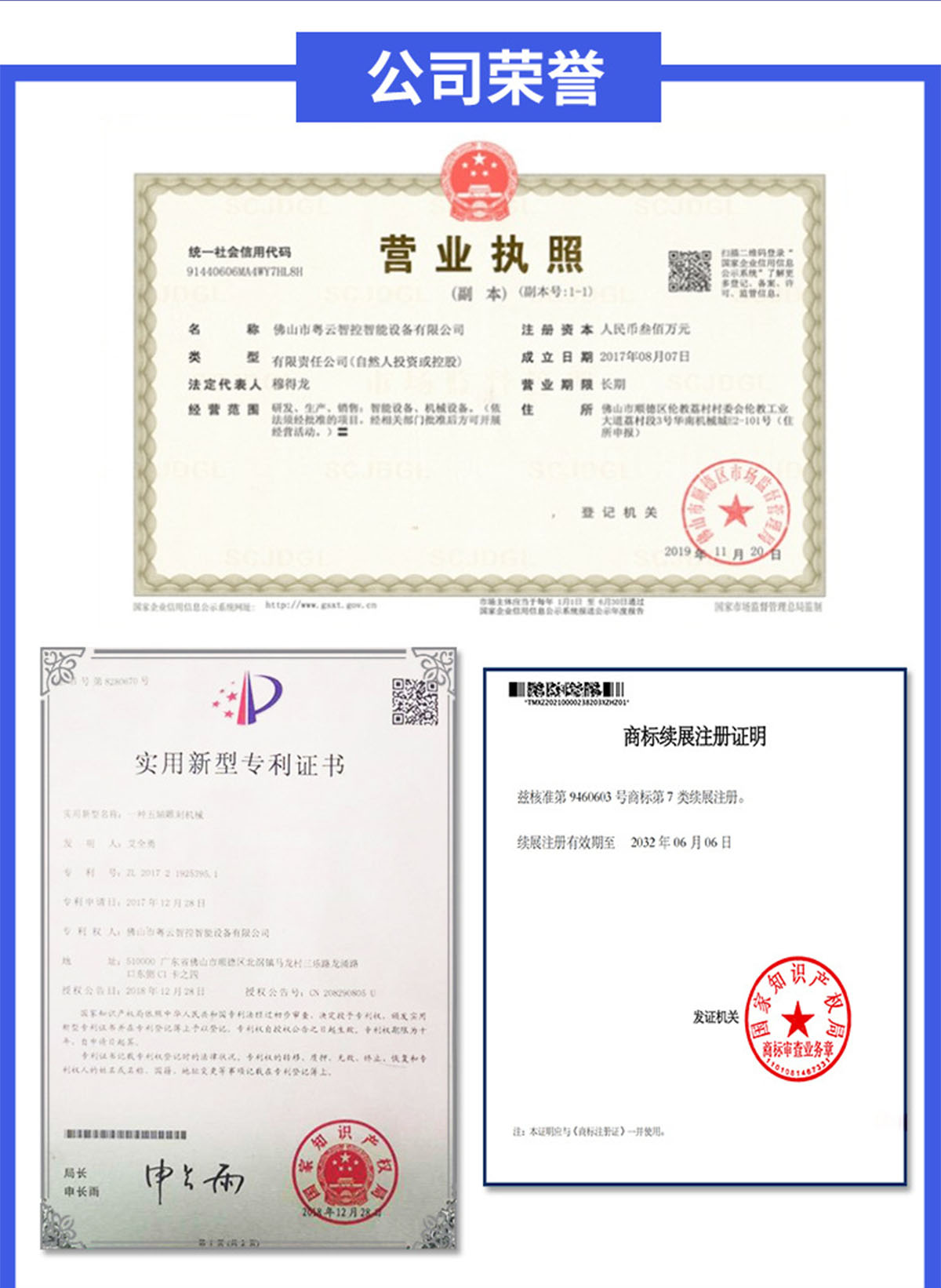

Produced by Foshan Yundiao Intelligent Control Intelligent Equipment Co., Ltd., the industrial aluminum profile drilling, tapping and milling machine is a comprehensive CNC machining equipment integrating drilling, tapping, milling and other functions, using advanced CNC technology and high-precision transmission system to achieve an automated, efficient and accurate machining process. The equipment is widely used in doors and windows, aluminum products, lighting, sanitary ware, building materials, curtain wall decoration and other industries.

Key features:

1.High-precision machining:

All holes and tapping positions of the equipment are processed and positioned by a special drilling and tapping center at one time, and the accuracy can reach plus or minus 0.02 mm.

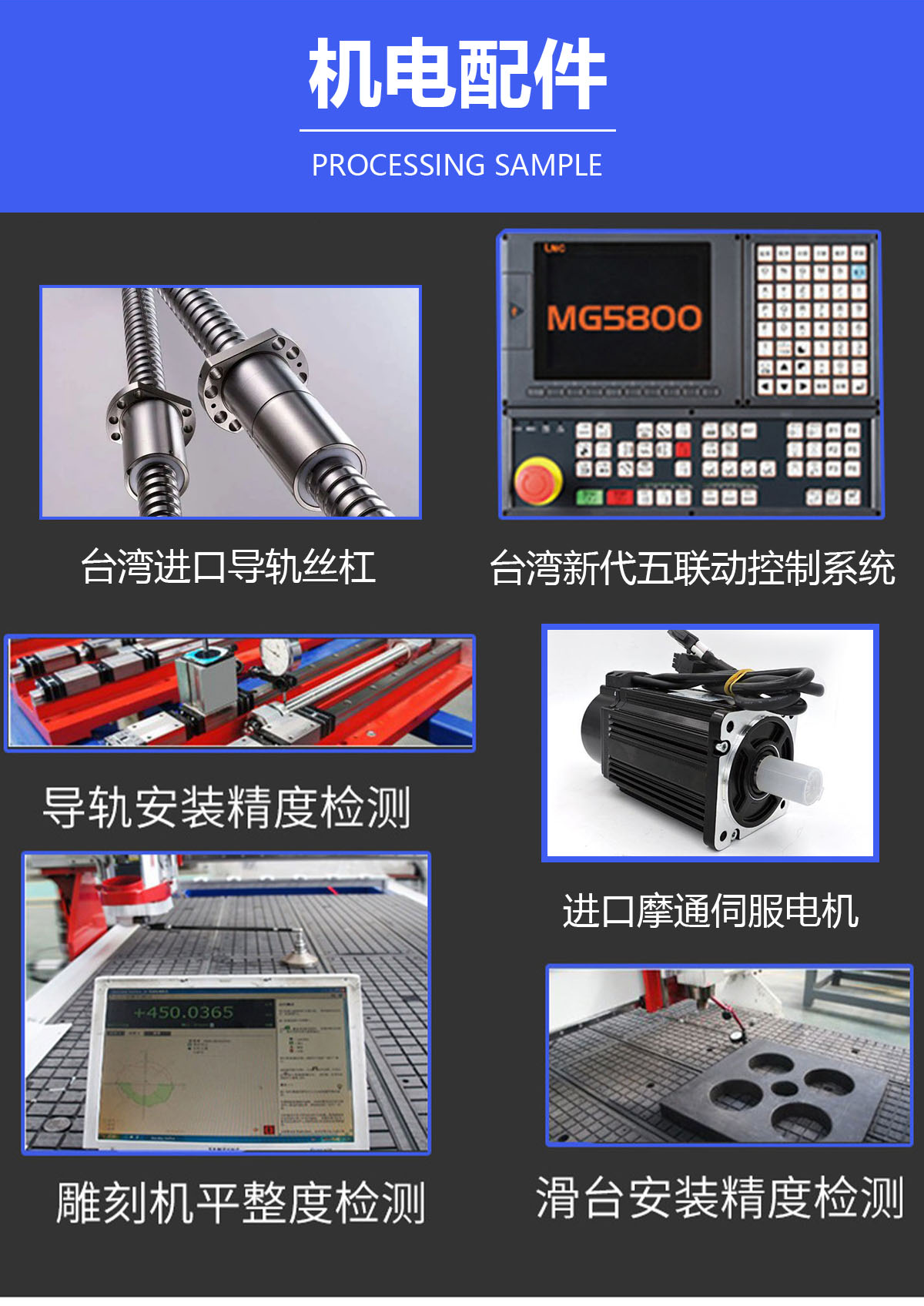

The transmission mechanism adopts Taiwan Shangyin and Japan THK linear guide rails, and the roller screw adopts Taiwan TBI brand to ensure the effective accuracy and system stability of the machine tool.

2.Efficient machining:

Equipped with a multi-axis linkage system, it can realize the processing of complex hole systems, such as oblique holes, cross holes, etc.

The spindle system adopts high-speed, high-precision motors, with a variety of tool clamping methods, to adapt to different diameters and lengths of tools.

The feed system adopts high-precision ball screws and linear guide rails to ensure the smoothness and accuracy of the feed movement, and at the same time realize fast positioning and high-speed cutting.

3.Versatility:

It integrates drilling, tapping, milling and other functions to meet the processing needs of aluminum profiles and other materials.

Support CNC automatic machining, and can generate processing programs through computer numerical control software to achieve automatic processing.

4.Stable and durable:

The overall structure of the equipment is sturdy and made of high-quality materials to ensure that it will not be deformed for long-term use.

Equipped with a cooling system to cool the cutting area and the tool, reduce the tool temperature and extend the tool life.

With its high precision, high efficiency, versatility and stable and durable characteristics, Yundiao industrial aluminum profile drilling, tapping and milling machine has become a powerful assistant in the aluminum profile processing industry. Whether in terms of machining accuracy, processing efficiency or processing range, it can meet the high requirements of modern manufacturing industry.

Related products