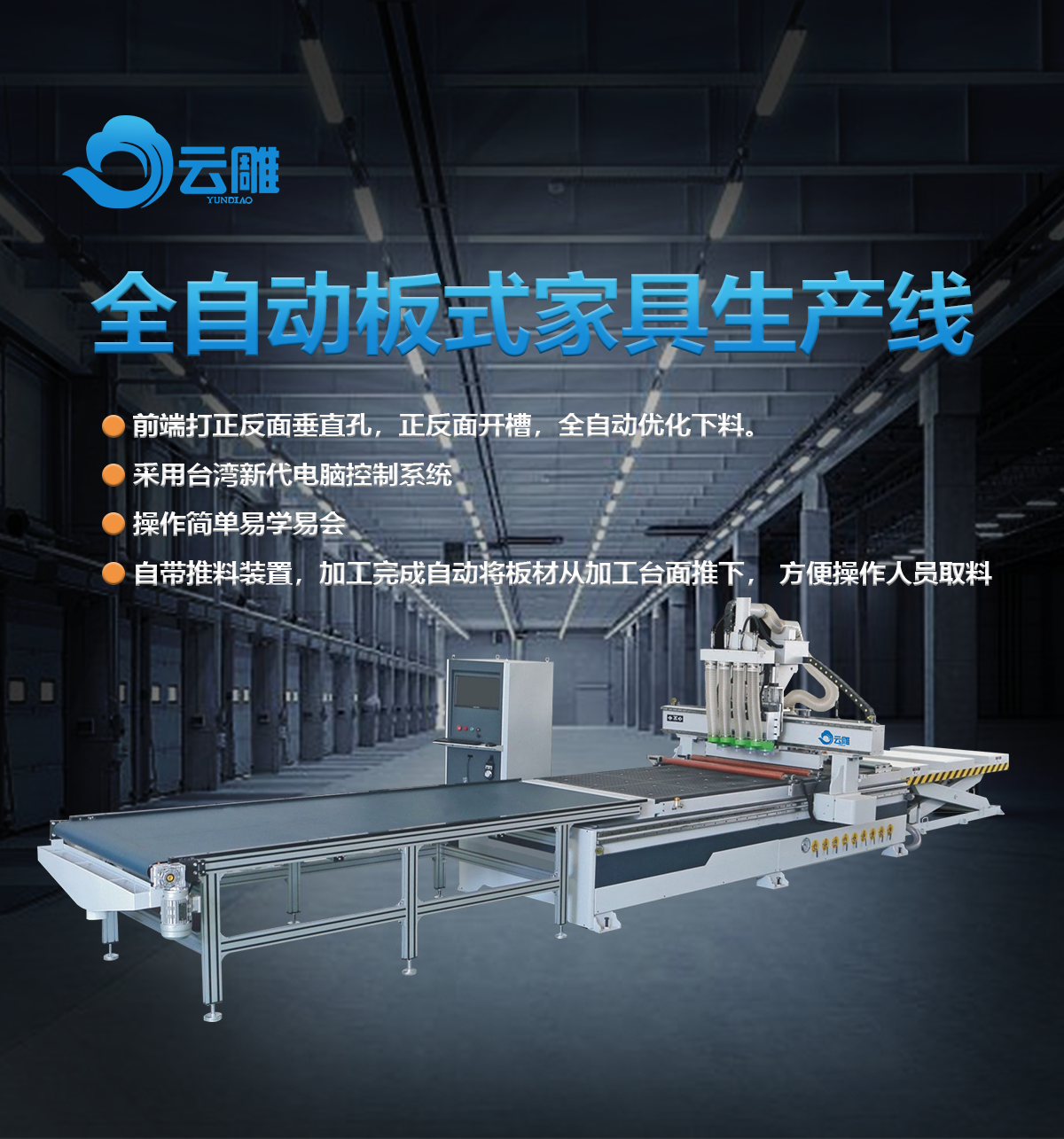

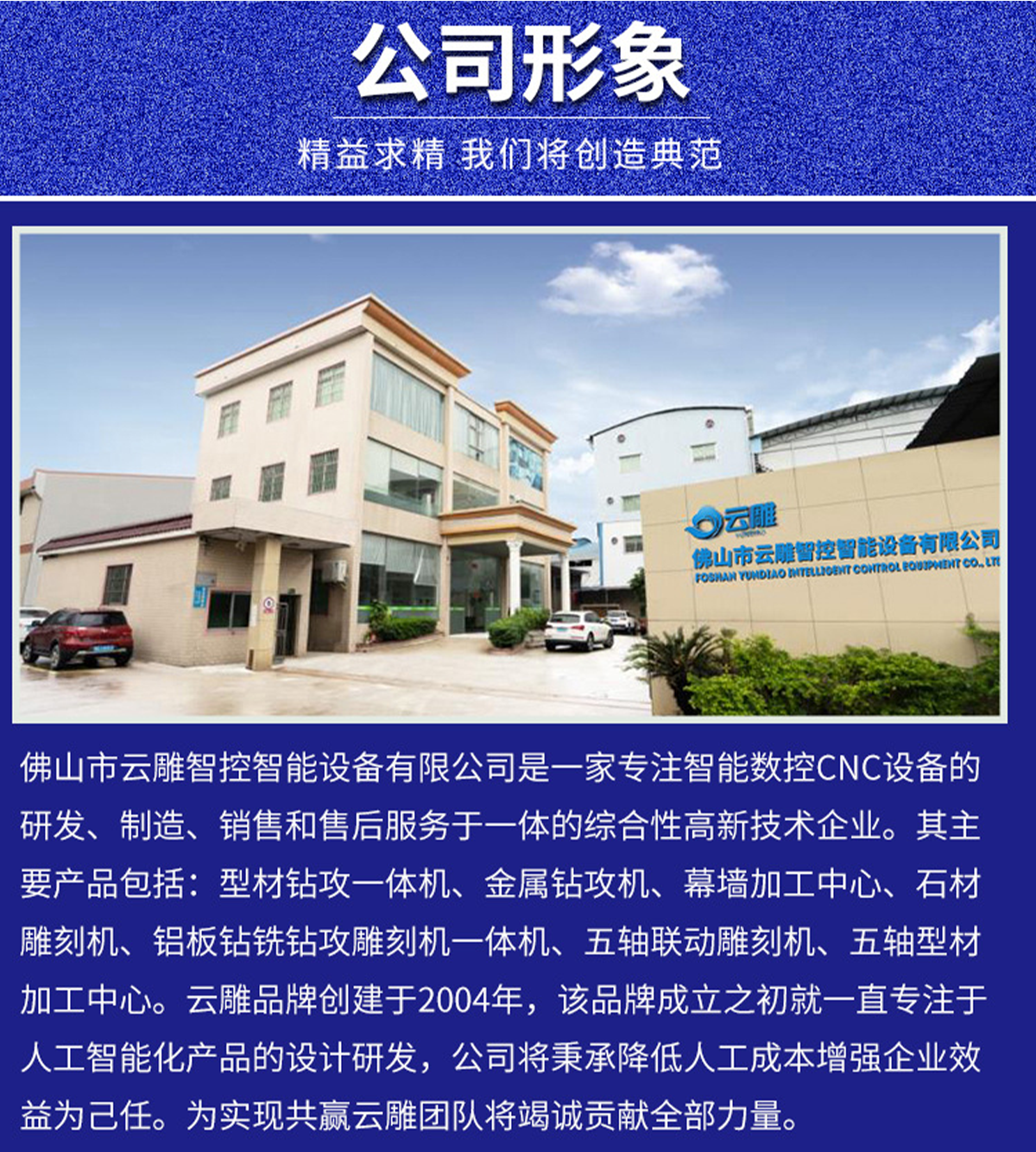

Panel furniture production line equipment The multi-head switching of the woodworking cutting machine is more efficient

Automatic panel furniture cutting machine production line, the equipment adopts four spindles, which can realize multi-process processing such as cutting, slotting, chamfering and forming, automatic loading and unloading, saving labor and being more competitive.

Product characteristics:

Category:

Woodworking equipment

Product attachments:

Keyword:

Panel furniture production line equipment The multi-head switching of the woodworking cutting machine is more efficient

contact us

Product Description

Yundiao panel furniture production line is a set of design, cutting, processing, edge banding, punching, assembly and other processes in one of the automated production line, designed for the production of panel furniture. It is widely used in the panel furniture manufacturing industry, including the production of wardrobes, cabinets, bookcases, wine cabinets and other furniture.

Key features:

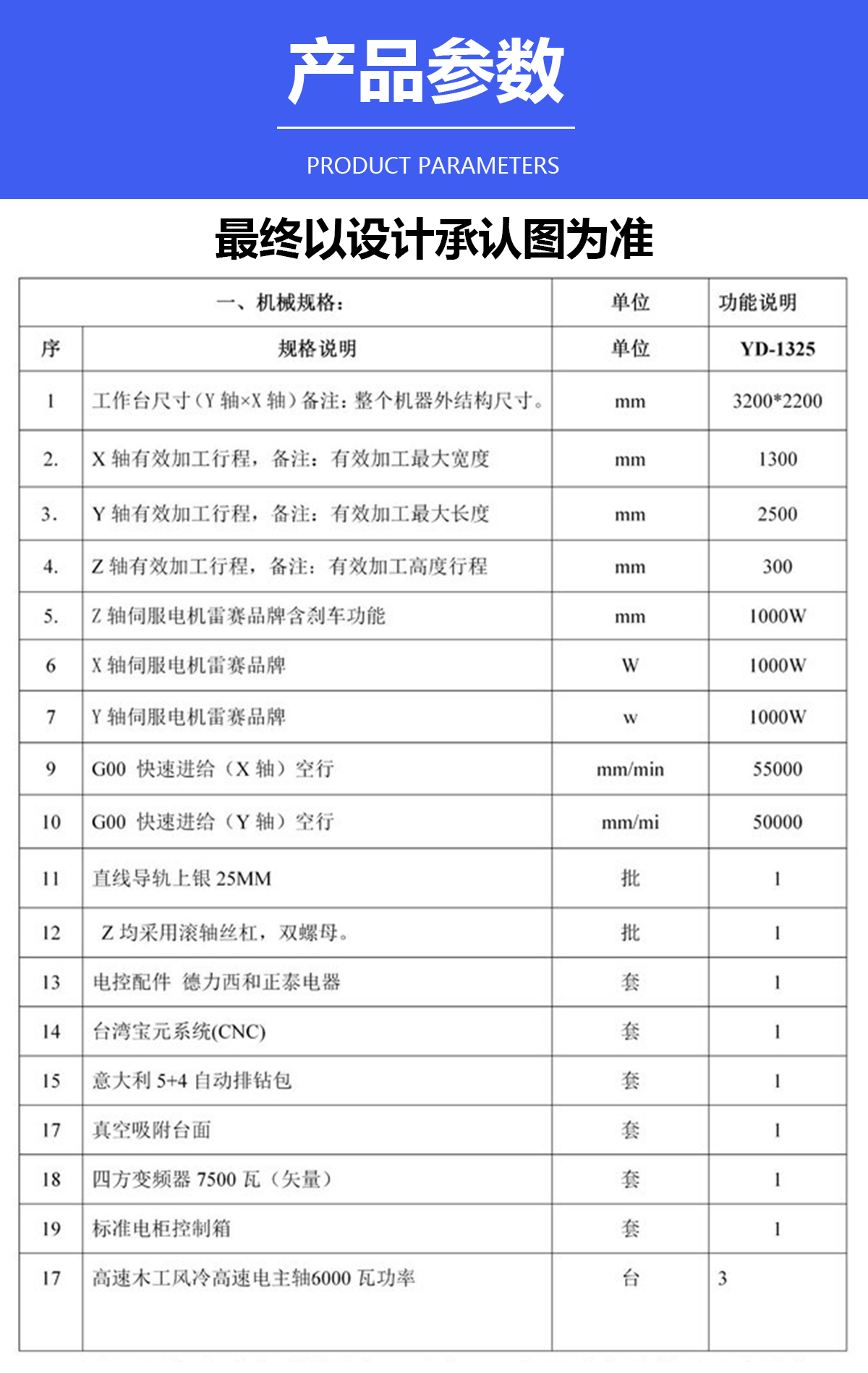

1.High-precision machining

The use of advanced numerical control technology and high-precision transmission system to ensure that the processing accuracy reaches the industry-leading level.

The machining accuracy can reach plus or minus 0.02 mm, which meets the high-precision requirements of furniture production.

2.Efficient production

High degree of automation, reduce manual intervention, improve production efficiency.

It supports continuous operation, reduces material change time, and improves the overall production speed.

3.Versatility

Integrate multiple functions such as cutting, edge banding, punching, and assembly to achieve one-stop production.

Customized production can be carried out according to customer needs to meet the needs of different furniture styles and sizes.

4.Stability & Durability

The overall structure of the equipment is sturdy and made of high-quality materials to ensure long-term stability.

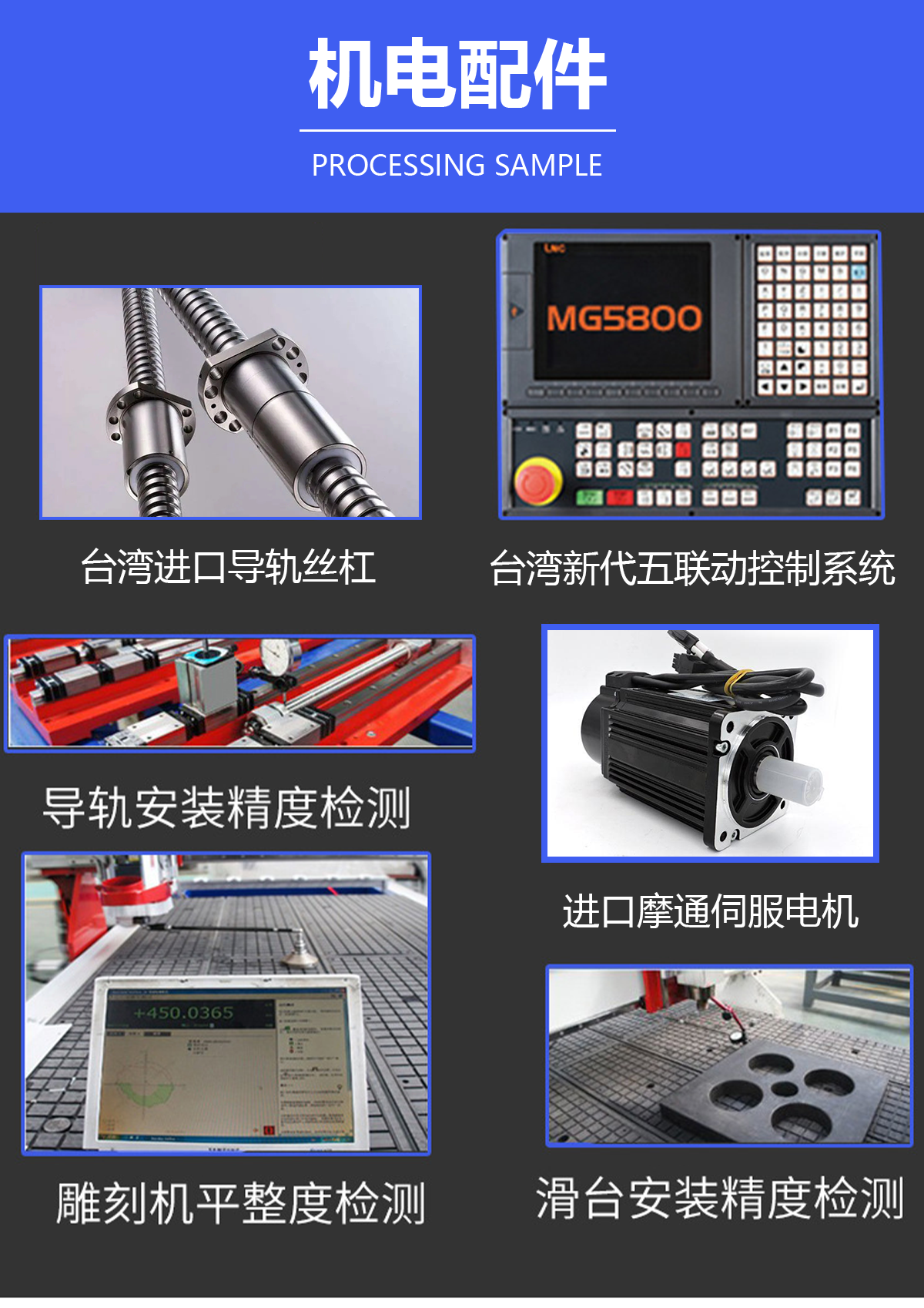

Key components such as spindles, guide rails, motors, etc. are all made of well-known brand products to improve the durability of the equipment.

It mainly consists of equipment

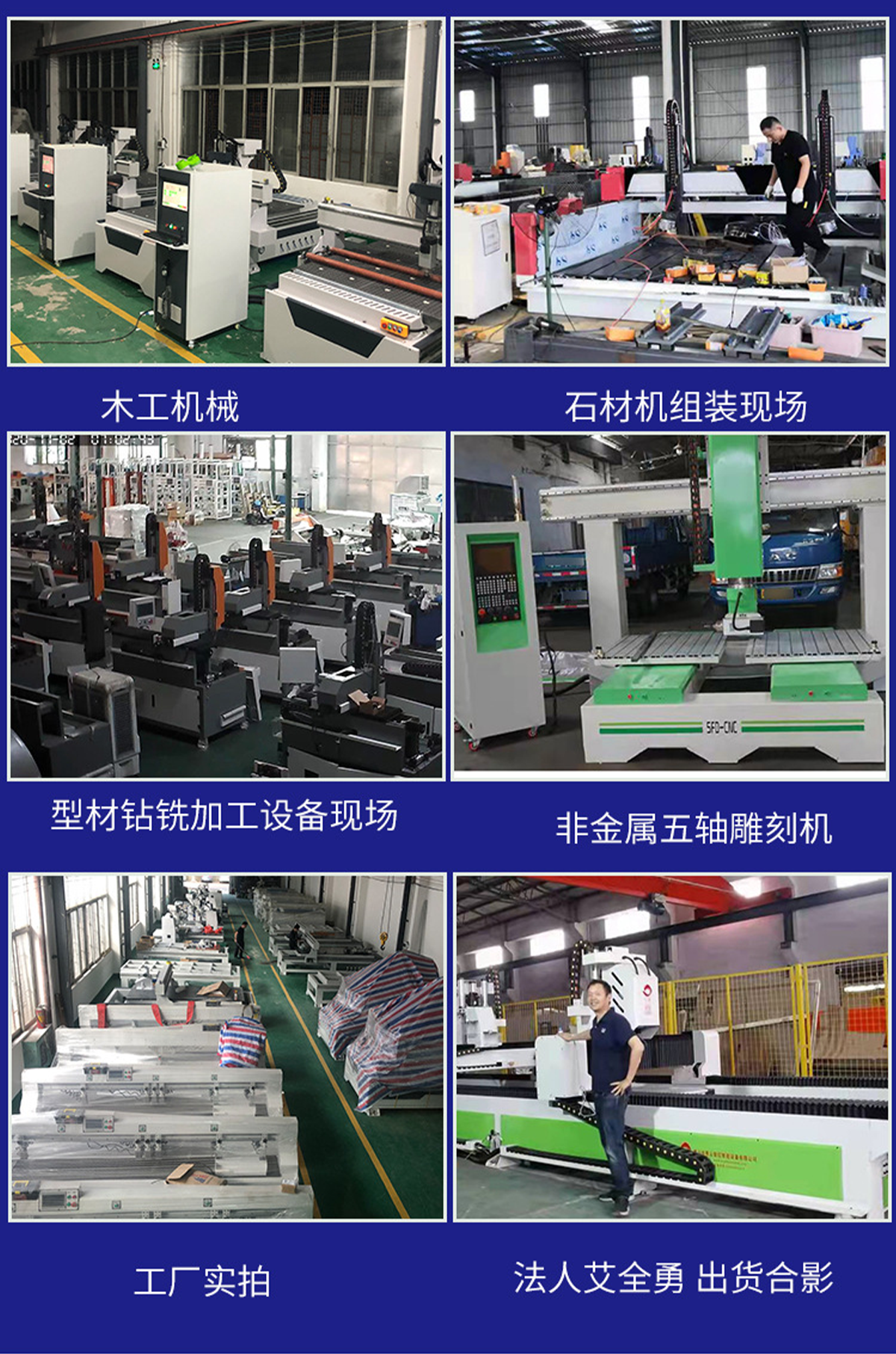

1. CNC cutting equipment

Including electronic cutting saw and CNC cutting machining center, which can be selected according to production needs.

The electronic cutting saw is suitable for batch standardized operations, and the CNC cutting machining center is suitable for customized processing needs.

2. Edge banding machine

Automatic edge banding technology is used to ensure that the edge banding effect is beautiful and durable.

It can be adjusted according to the material and thickness of the furniture panel to meet different production needs.

3. CNC row drilling machining center

Responsible for the drilling operation of furniture panels, supporting multi-axis linkage to realize the processing of complex hole systems.

Equipped with high-precision drills and fixtures to ensure punching accuracy and stability.

4. Automatic conveying system

The various processes are connected to realize the automatic conveying and positioning of the plates.

Reduce manual handling and positioning time, and improve productivity and accuracy.

5.Central control system

Responsible for the scheduling and control of the entire production line to ensure that each process is carried out in an orderly manner.

It supports remote monitoring and fault diagnosis functions, which is convenient for production management and maintenance.The cloud carved panel furniture production line has been successfully applied to a number of furniture manufacturing enterprises, realizing the automatic and efficient production of panel furniture. The furniture products produced by this production line have the characteristics of high precision, good quality and diverse styles, which meet the market demand and have been recognized by customers. With its high precision, high efficiency, versatility and stable and durable characteristics, it has shown strong competitiveness in the panel furniture manufacturing industry. The production line not only improves production efficiency and quality stability, but also reduces labor costs and production cycles, bringing significant economic benefits and market competitiveness to furniture manufacturing enterprises.

Related products