Cloud carving automatic edge banding machine

The automatic edge banding machine is a state-of-the-art equipment specially designed to handle panel edge banding, which achieves precise and efficient edge banding of sheet edges through highly automated operation.

Product characteristics:

Category:

Woodworking equipment

Product attachments:

Keyword:

Cloud carving automatic edge banding machine

contact us

Product Description

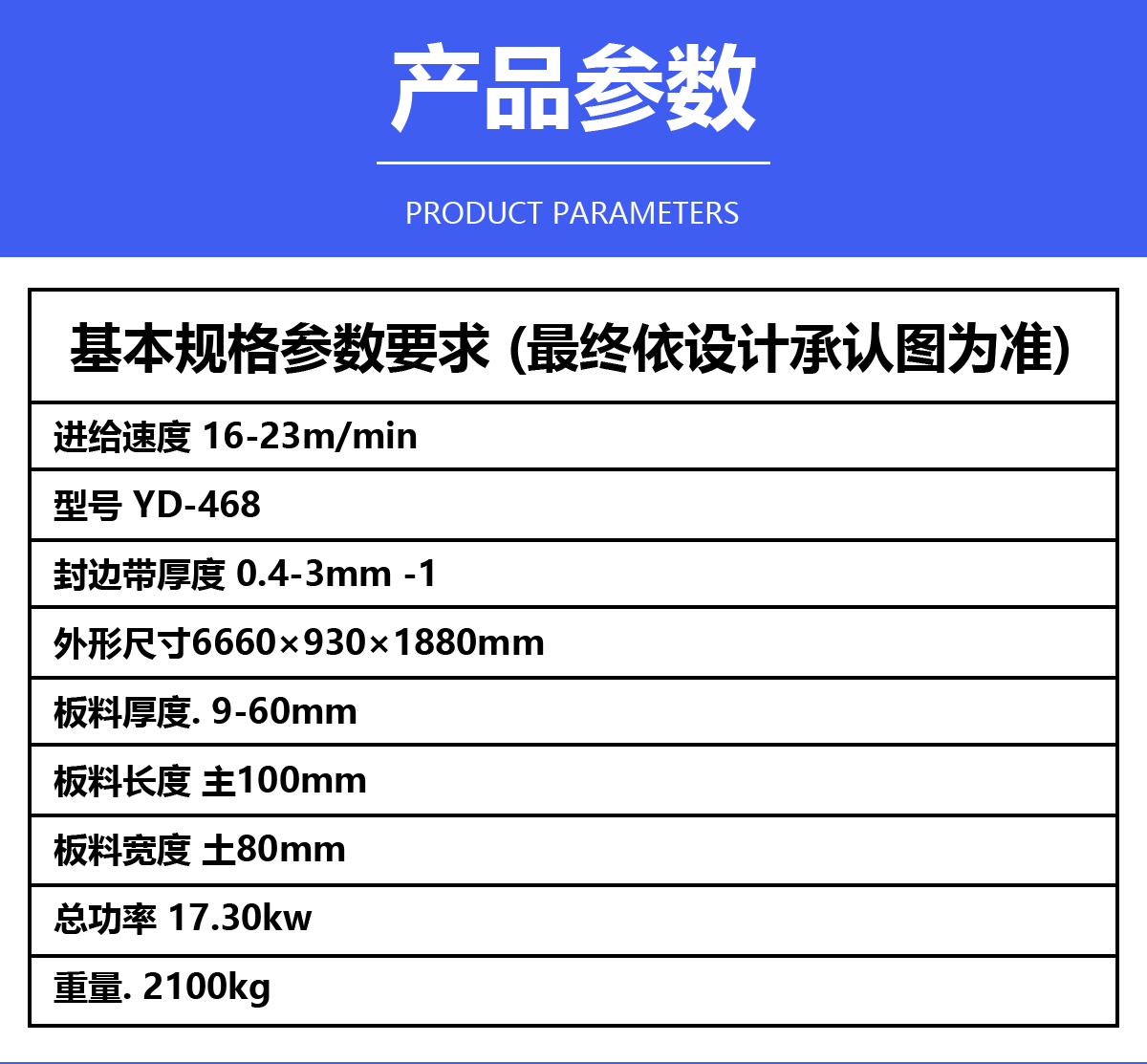

Yundiao automatic edge banding machine is a kind of woodworking machinery and equipment widely used in the production of panel furniture, it adopts automation technology, which can automatically complete the entire edge banding process from conveying, gluing welt, cutting to front and back flush, trimming up and down, polishing, etc.

Features:

1. High degree of automation:The automatic edge banding machine realizes the fully automated operation from sheet feeding to edge banding, which reduces manual intervention and labor intensity.

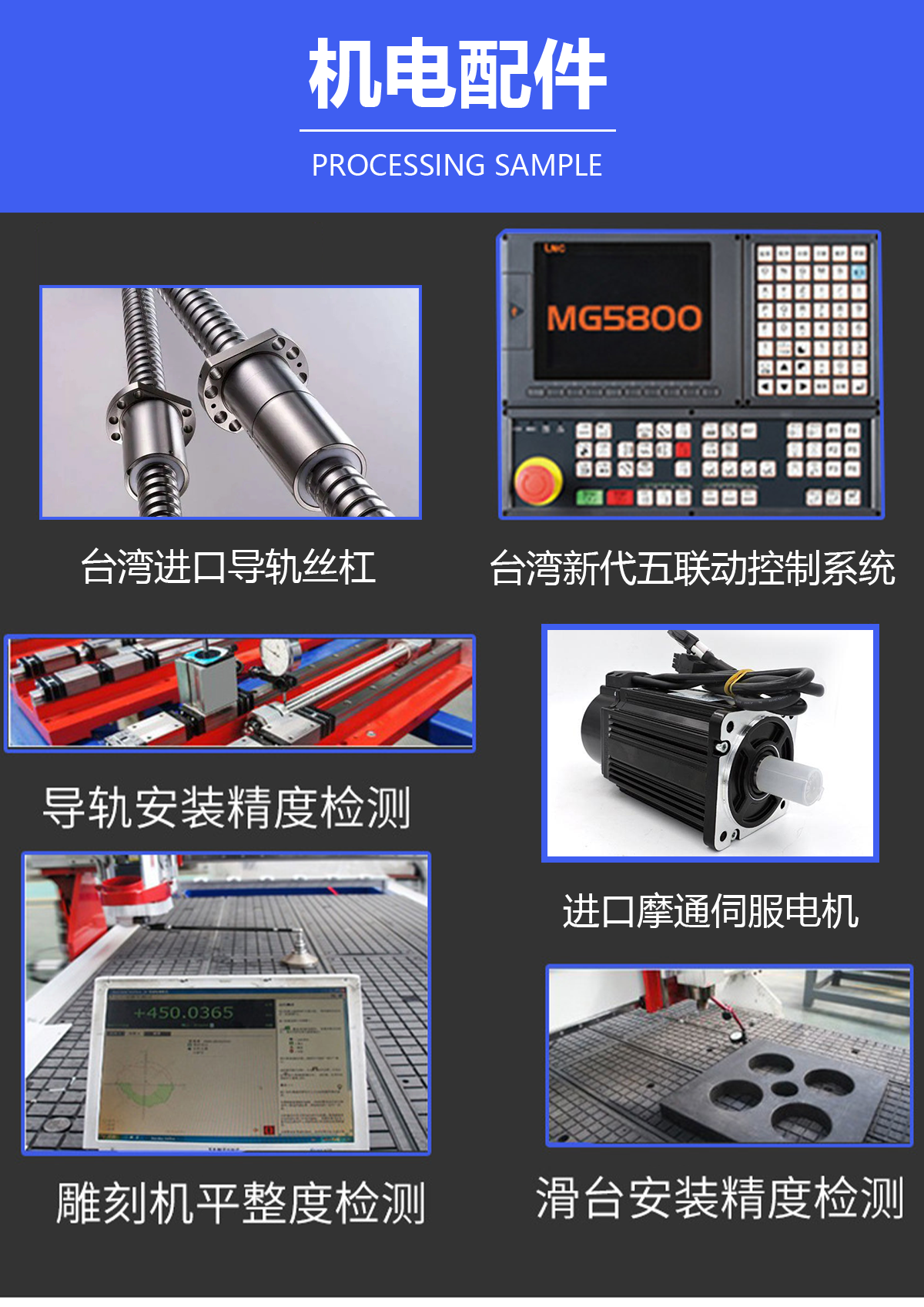

2. High efficiency:Using advanced edge banding technology and automatic control system, the edge banding process can be completed quickly and accurately, and the production efficiency can be improved. At the same time, the automatic feeding and receiving functions also further improve the work efficiency.

3. High precision:Through the precise mechanical structure and control system, the length and angle of the edge banding can be precisely controlled to ensure the quality and consistency of each plate.

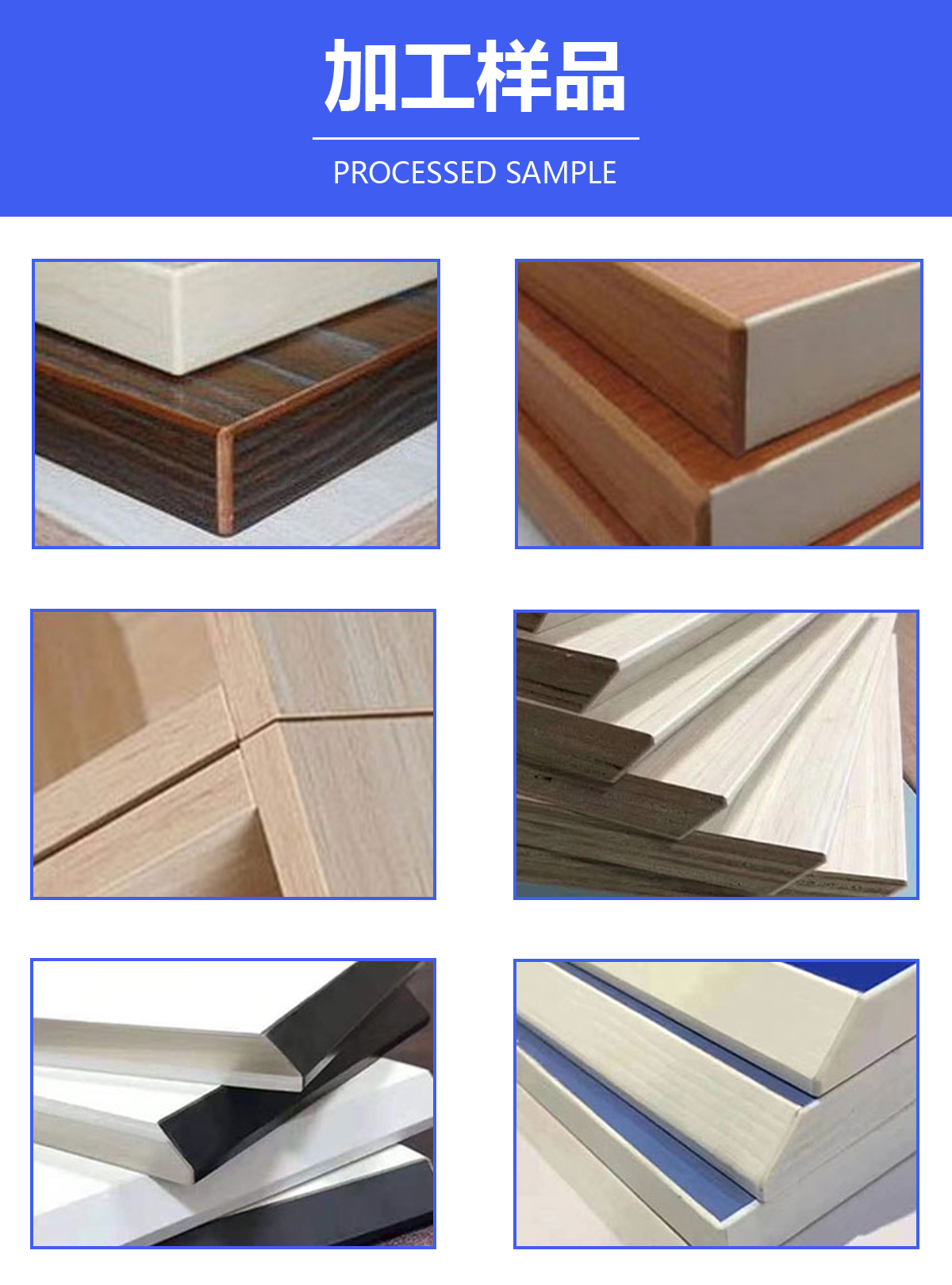

4. Versatility:Automatic edge banding machines usually have a variety of functions, such as single-sided trimming, double-sided trimming, chamfering, etc., to adapt to the edge banding needs of different panels.

5. Environmental protection and energy saving:The use of advanced energy-saving technology and environmentally friendly materials to reduce energy consumption and noise pollution, in line with the requirements of modern production environmental protection.The automatic edge banding machine is mainly composed of the fuselage, various processing departments, control systems and other parts. The processing components mainly include pre-milling, gluing, edge banding, flushing, rough trimming, finishing, profiling tracking, edge scraping, polishing, grooving, etc. (optional). It is used in panel furniture, furniture accessories, cabinets, doors and windows and other fields. It can process a variety of man-made panels, such as particle board, MDF, multi-layer board, etc., to meet different production needs.

last page

Related products