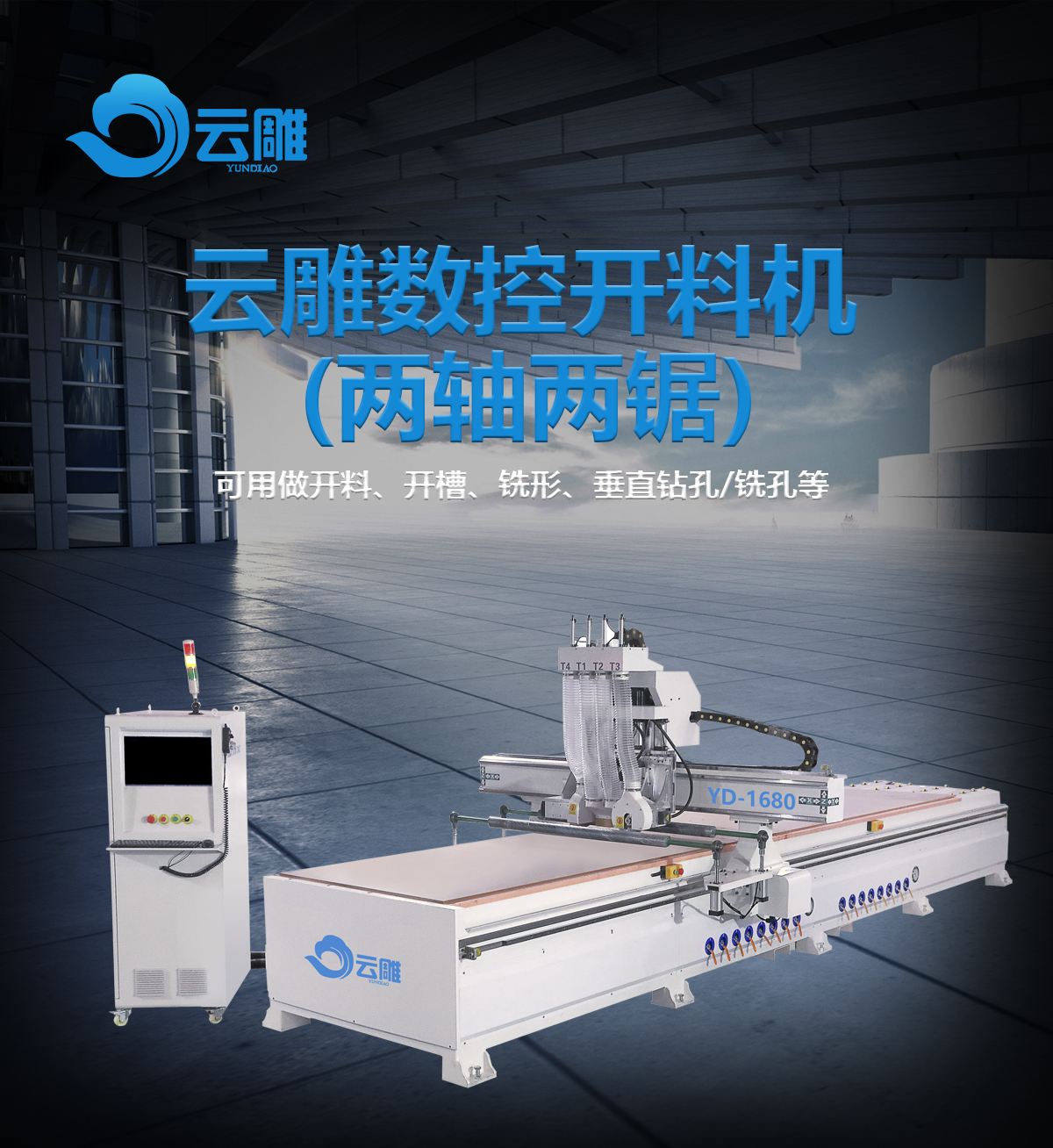

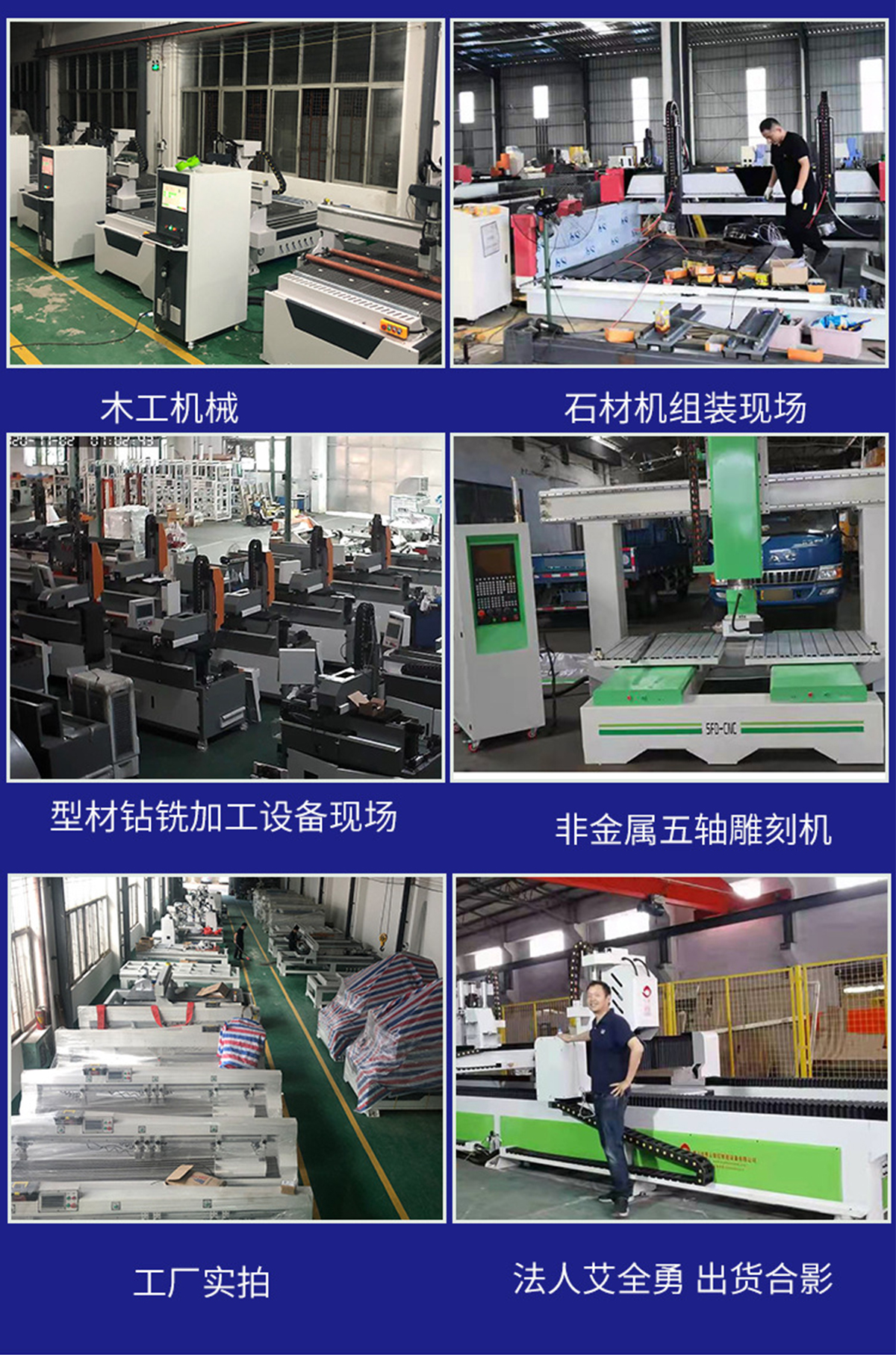

Apron cutting machine production base

Performance characteristics panel furniture cutting machine, using sawing machine, to achieve fully automatic production in honeycomb panel, panel furniture and other industries, the equipment can reduce labor costs, improve production efficiency, cutting smooth and burr-free

Product characteristics:

Category:

Woodworking equipment

Product attachments:

Keyword:

Apron cutting machine production base

contact us

Product Description

Panel furniture cutting machine, especially the type with the design of the sawing machine, is an important equipment in the modern furniture manufacturing industry. This kind of equipment integrates sawing and processing functions, and can complete a variety of processes such as positioning, cutting, punching, and slotting of the plate at one time, which greatly improves the production efficiency and processing accuracy.

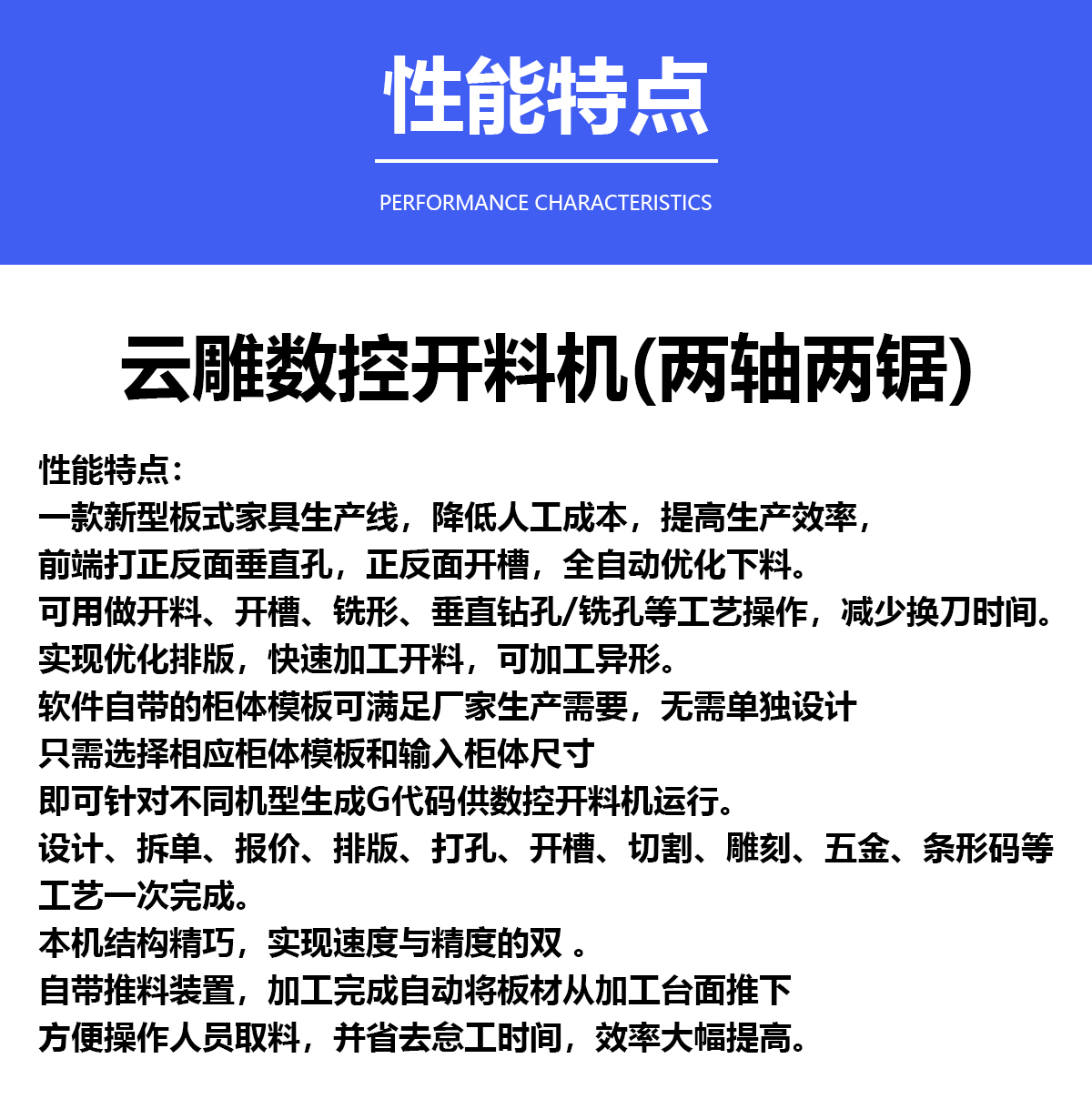

Key features:

1.High-precision machining:

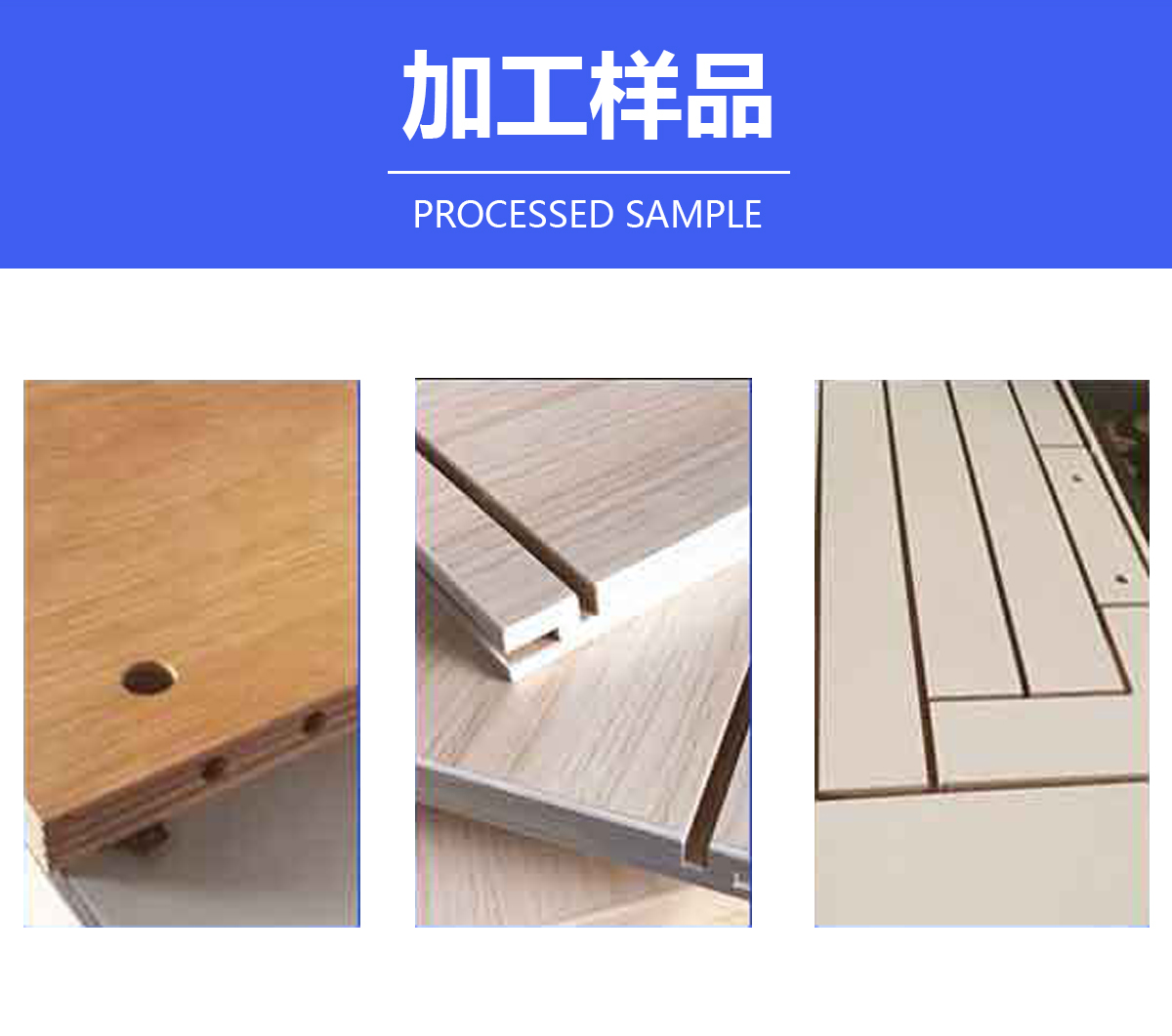

The machining accuracy can reach a high level, such as the repeated positioning accuracy can reach ±0.02mm, to ensure the accurate docking and installation of furniture parts.

High-quality saw blades and machining tools are used to ensure the finish and flatness of the cutting and machined surfaces.

2.Efficient production:

The high degree of automation realizes CNC automatic processing, cancels the template making, marking operation, wire saw cutting and rough machining process in the production process of traditional special-shaped solid wood panels, and simplifies the operation process.

Support a variety of processing modes, such as punching, slotting, cutting, etc., a variety of processing tasks can be completed in one clamping, improve production efficiency.

3.Stable and durable:

The machine is designed with an integral steel structure, and the bed is thickened and specially treated to ensure stability and durability for long-term use.

Key components such as spindle motors, servo motors, etc. adopt well-known brand products, with reliable quality and low failure rate.

4.Easy to operate:

Humanized industrial control system and operation interface are adopted, without complex programming, and the operation is simple and efficient.

It is equipped with an automatic feeding and discharging system to reduce the labor intensity of workers and improve production safety.The panel furniture cutting machine sawing machine is widely used in the modern panel furniture manufacturing industry, including the production and processing of wardrobes, cabinets, wine cabinets, tatami mats and other furniture. It can meet the needs of the custom furniture market for efficient, accurate and diversified production, and is an indispensable processing equipment for furniture factories.

last page

Related products