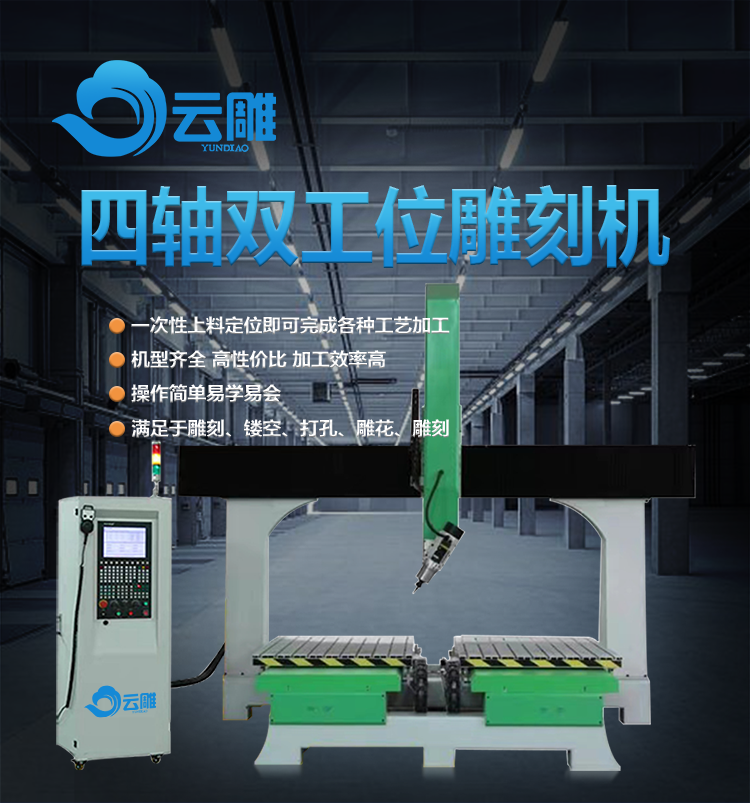

Four-axis double-station bent plate surface cutting machine

The four-axis double-station wood mold engraving machine is satisfied with carving, hollowing, trimming, drilling, etc., and is a multi-functional mold engraving processing center. The operation is simple, easy to learn and easy to learn. ...

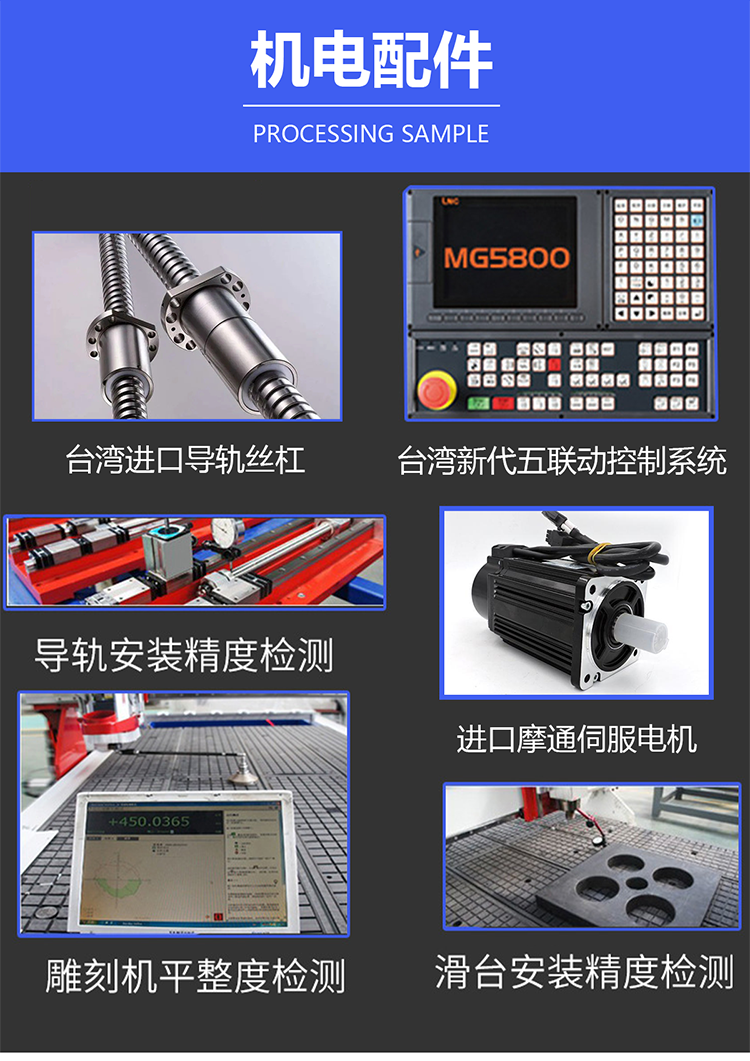

Product characteristics:

Category:

Four axis engraving machine

Product attachments:

Keyword:

Four-axis double-station bent plate surface cutting machine

contact us

Product Description

The important application of five-axis non-metal CNC cutting machines in the field of aviation composites

In the aerospace field, the application of advanced materials continuously drives technological progress. Composite materials have become key materials for manufacturing aircraft structural components due to their outstanding performance. Meanwhile, five-axis non-metal CNC cutting machines, as high-precision and high-efficiency processing equipment, play a crucial role in the aviation composites sector.

Aerospace composites typically feature complex structures and strict precision requirements. The five-axis non-metal CNC cutting machine, with its multi-axis linkage capability, can easily handle the cutting demands of complex shapes. Whether it is the streamlined contour of an aircraft wing or the complex curved surface of a fuselage component, this cutting machine can precisely cut the composite materials into the required shapes, ensuring perfect matching and assembly accuracy between parts.

Compared with traditional cutting methods, five-axis CNC cutting machines have obvious advantages when processing aviation composites. Traditional cutting may cause damage to the material edges, fiber breakage, and dimensional deviations, thereby affecting the performance and reliability of components. However, five-axis cutting machines, with advanced CNC technology and precise tool path planning, can achieve smooth and undamaged cutting, maximizing the retention of the original performance of the composite materials and improving the quality and service life of aviation components.

In the manufacturing process of aviation composites, efficiency is equally crucial. Five-axis non-metal CNC cutting machines can complete cutting tasks quickly and efficiently. Their highly automated operation mode reduces manual intervention, not only lowering human error but also significantly enhancing production efficiency. By pre-programming the cutting parameters and paths, the cutting machines can work continuously and stably, greatly shortening the production cycle and meeting the strict requirements of the aviation industry for rapid delivery.

In addition, the five-axis cutting machine also features excellent versatility and flexibility. It can adapt to various types and specifications of aviation composites, including carbon fiber reinforced composites, glass fiber reinforced composites, and other new types of non-metallic composites, all of which can be precisely cut. Moreover, for parts of different sizes and shapes, simply adjusting the numerical control program allows for quick switching of production, meeting the demands of small-batch and diverse production.

Under the extremely high requirements for safety and reliability in the aerospace field, the precise cutting of five-axis non-metal CNC cutting machines helps to reduce the weight of aircraft, optimize structural design, improve fuel efficiency, and enhance flight performance. Moreover, its high-quality cutting results can reduce the risk of faults caused by material defects or processing errors, ensuring flight safety.

In conclusion, the application of five-axis non-metallic CNC cutting machines in the field of aviation composites is an inevitable choice for modern aviation manufacturing to pursue high performance, high efficiency and high quality. With the continuous progress and innovation of technology, it is believed that this advanced processing equipment will play a more important role in the future aerospace field and inject strong impetus into the development of the aviation industry.

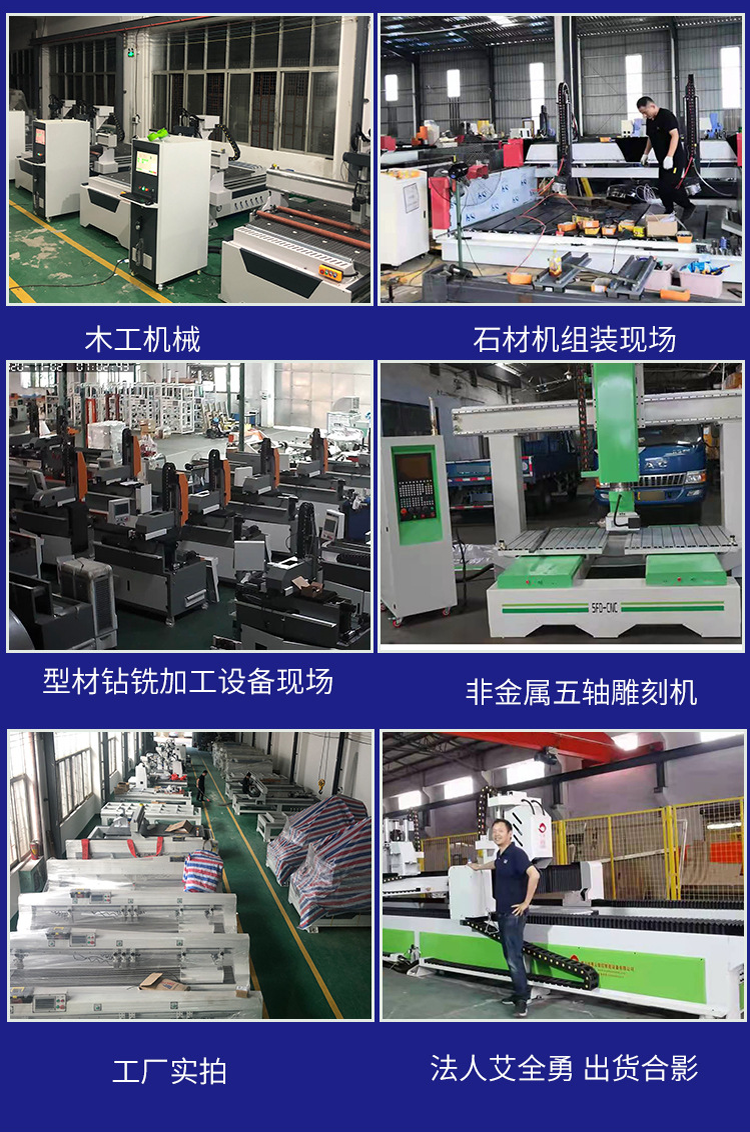

Double-station four-axis engraving machine is an efficient and multi-functional processing equipment, which is widely used in the engraving and cutting of woodworking, stone, metal and other materials.

Key features

1. Double-station design:

Efficient production:The two stations can work independently or simultaneously for continuous processing and reduced waiting times.

Flexible switching:The station can be easily switched according to needs to adapt to different processing needs.

2. Four-axis linkage:

Versatility:The four-axis linkage design enables the engraving machine to complete more complex three-dimensional engraving and plane processing tasks.

High precision:The multi-axis linkage improves the accuracy and delicacy of the engraving.

3. Material adaptability:

Wide range of applications:It is suitable for the processing of wood, stone, metal, plastic and other materials.

Flexible configuration:Tools and machining parameters can be adjusted according to different materials.

Application scenarios

Woodworking industry:It is used for carving and cutting wood products such as furniture, doors and windows, flooring, etc.

Stone industry:It is used for the processing of stone reliefs, tombstones, stone handicrafts, etc.

Metalworking:It is suitable for engraving and cutting metal plates and pipes, such as metal signs, metal crafts, etc.

Other areas:It can also be used for the processing of plastics, glass and other materials, as well as advertising, molds, handicrafts and other industries.With its efficient, flexible and multi-functional characteristics, double-station four-axis engraving machine has been widely used in many industries.

Related products