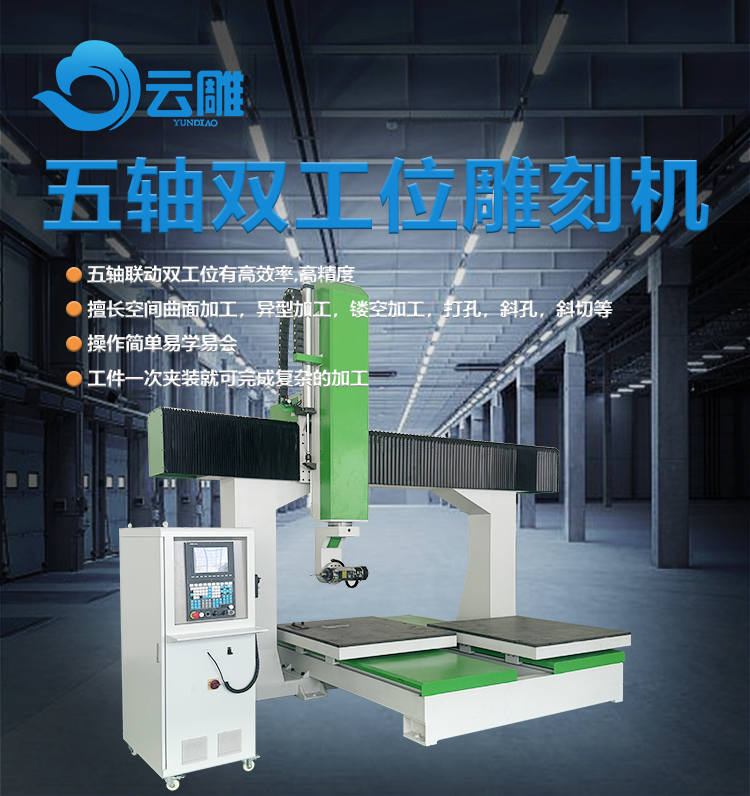

Five-axis double-station CNC engraving machine

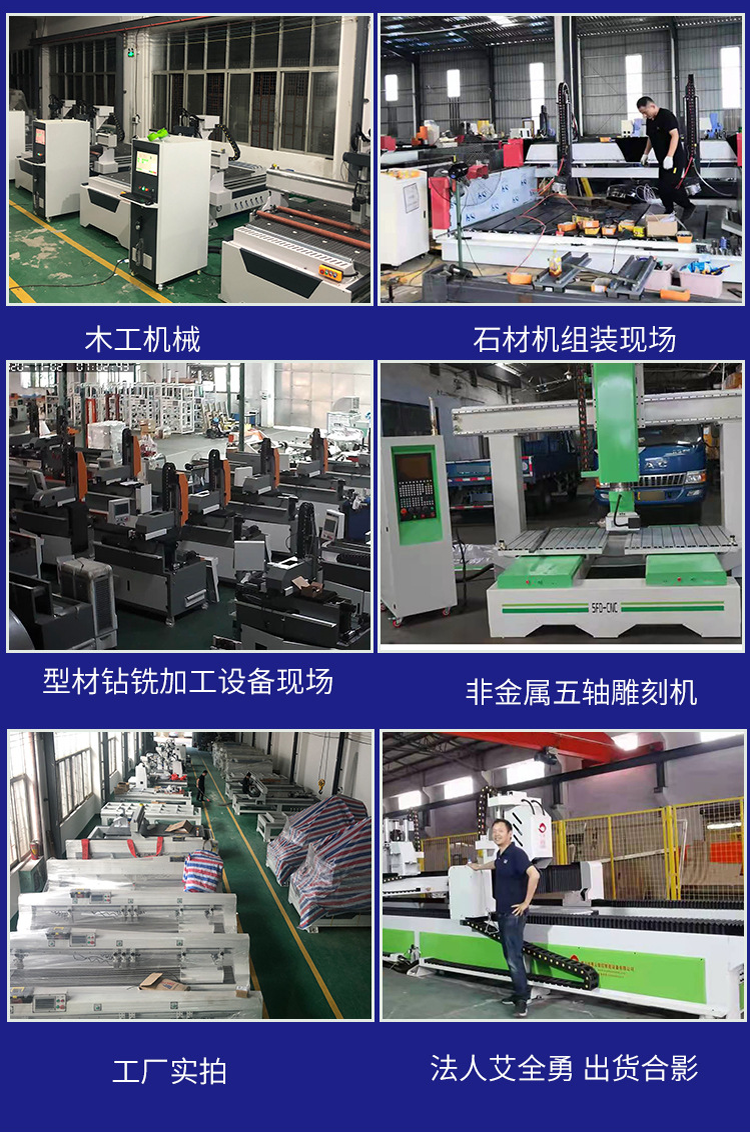

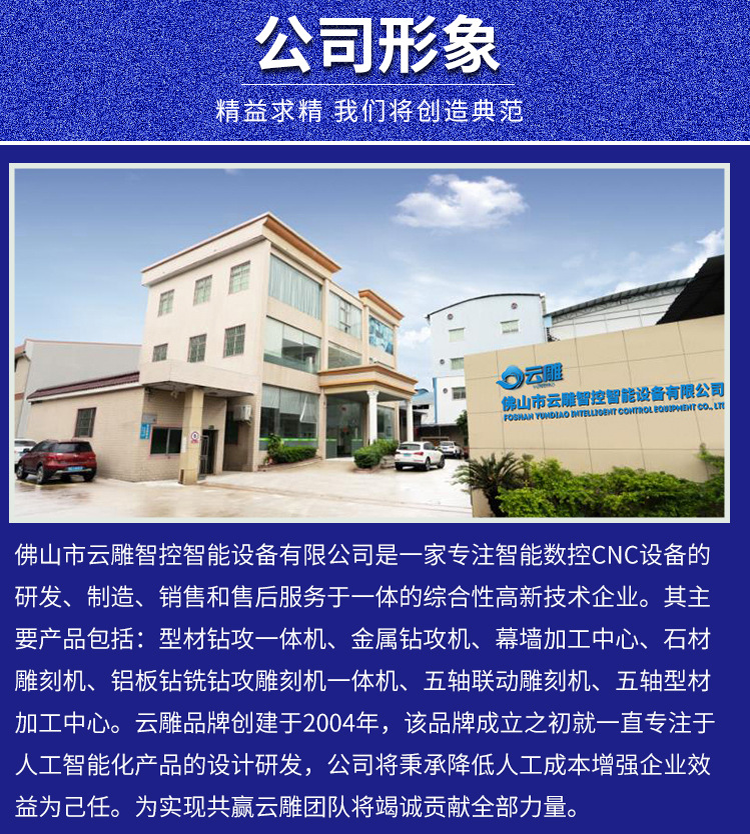

Yundiao five-axis non-metallic machining center equipment source manufacturers, spot supply is worth looking forward to

Product characteristics:

Category:

Five axis engraving machine

Product attachments:

Keyword:

Five-axis double-station CNC engraving machine

contact us

Product Description

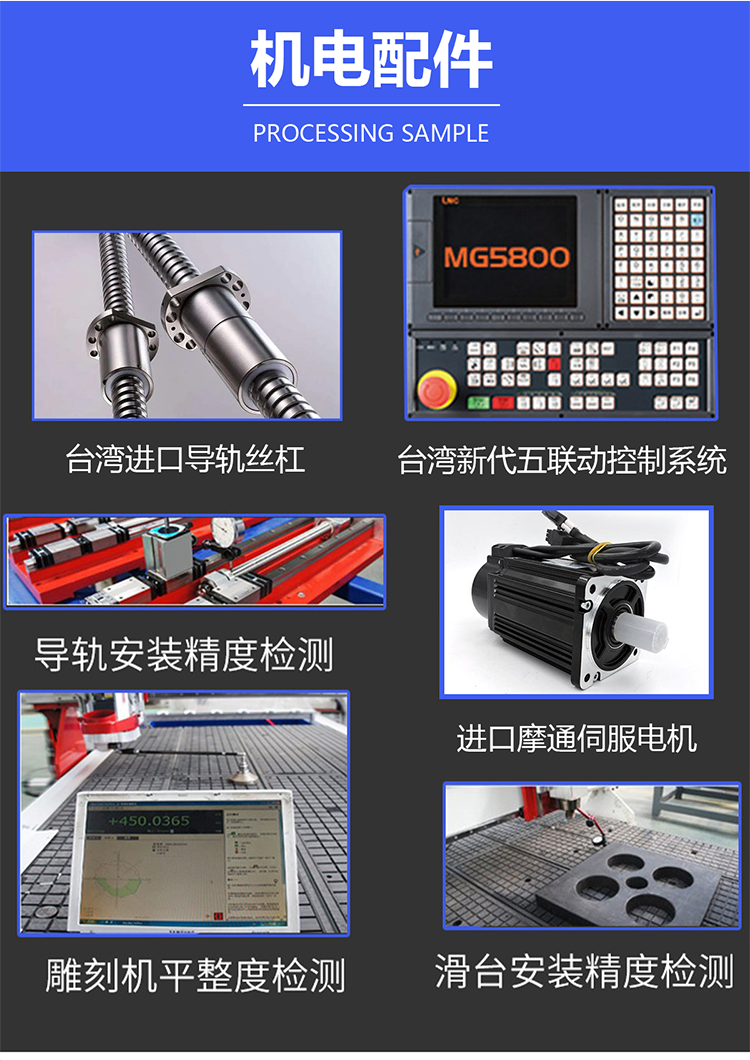

1.Equipment performance and characteristics:The five-axis blister mold engraving machine has high precision and high efficiency processing capabilities, and it can realize the processing of complex three-dimensional surfaces and contours, which is difficult to do on traditional three-axis machines. Thanks to the addition of five-axis technology, the engraving machine can process at multiple angles and directions, which greatly improves the flexibility of processing and the accuracy of the product.

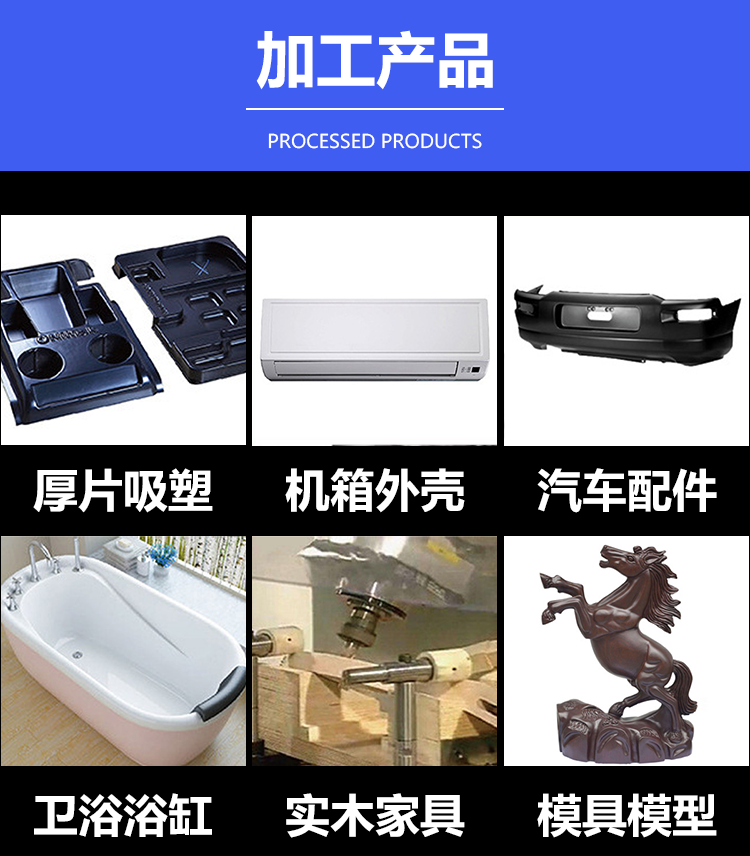

2.Main application areas:This engraving machine is mainly used to process blister molds made of plastic, aluminum, foam, resin and other materials. It is widely used in automotive, aviation, furniture, handicrafts, packaging and other industries, especially in the manufacture of complex curved surfaces and special shapes of molds showing its unique advantages.

3.Technological innovation and advantages:The five-axis blister mold engraving machine adopts advanced CNC technology, which can automatically complete complex processing tasks through pre-set programs. At the same time, due to its high degree of automation and precise control, the error rate of machining is extremely low, which greatly improves the quality and consistency of the mold

Related products