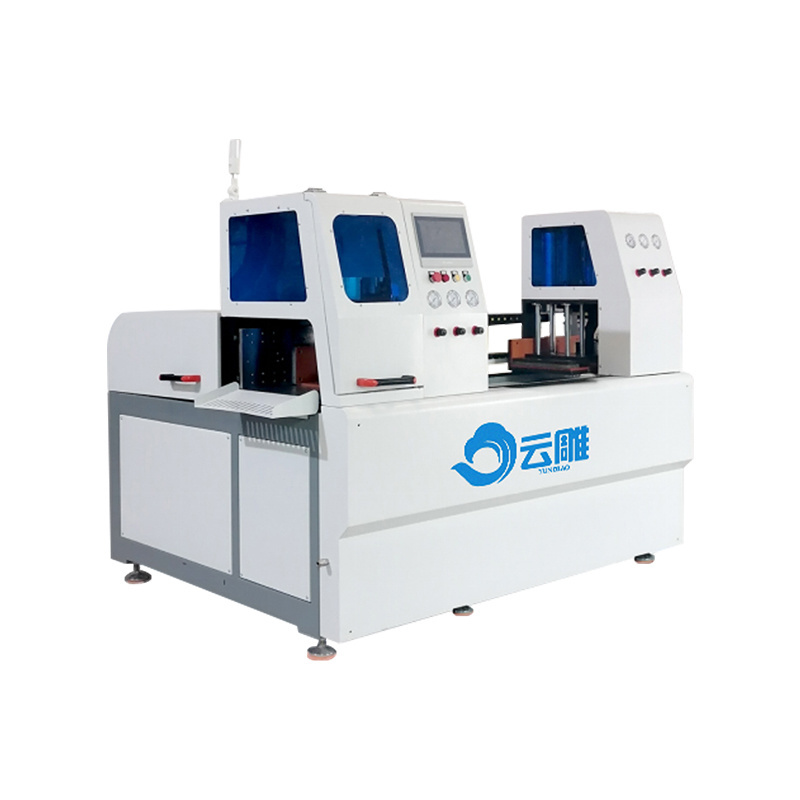

Industrial profile drilling and tapping machine

Industrial profile drilling and tapping machine is a kind of machine tool equipment that integrates drilling and tapping functions. It uses numerical control technology to achieve efficient and accurate automatic processing. The equipment has the characteristics of strong flexibility, easy operation and good stability, which is suitable for the processing needs of various industrial profiles, and improves the production efficiency and product quality.

Product characteristics:

Category:

Profile processing equipment

Product attachments:

Keyword:

Industrial profile drilling and tapping machine

contact us

Product Description

The industrial profile drilling and tapping machine is operated by CNC numerical control system, which can complete the specified process efficiently and accurately, saving time and effort.

How it works

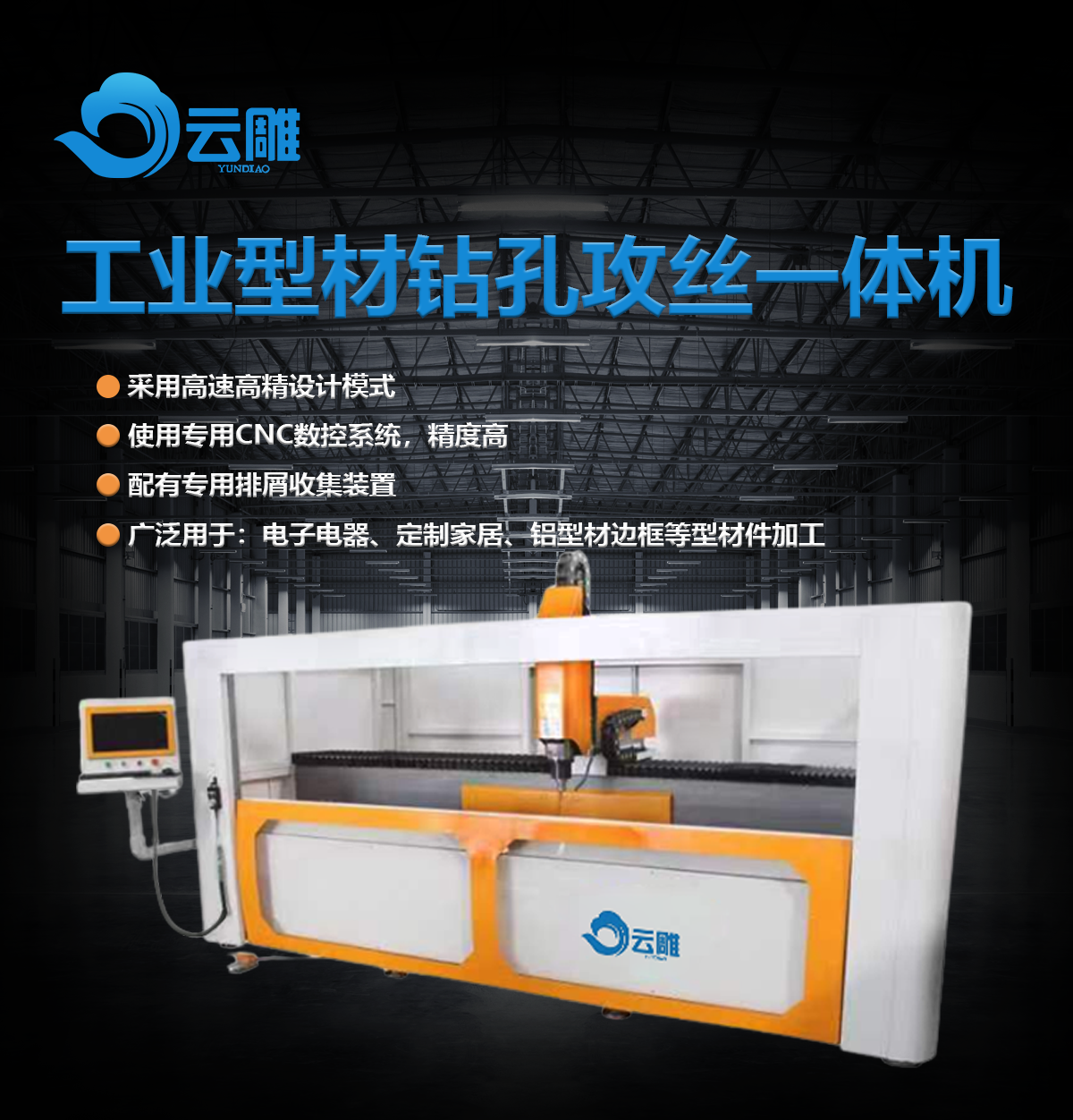

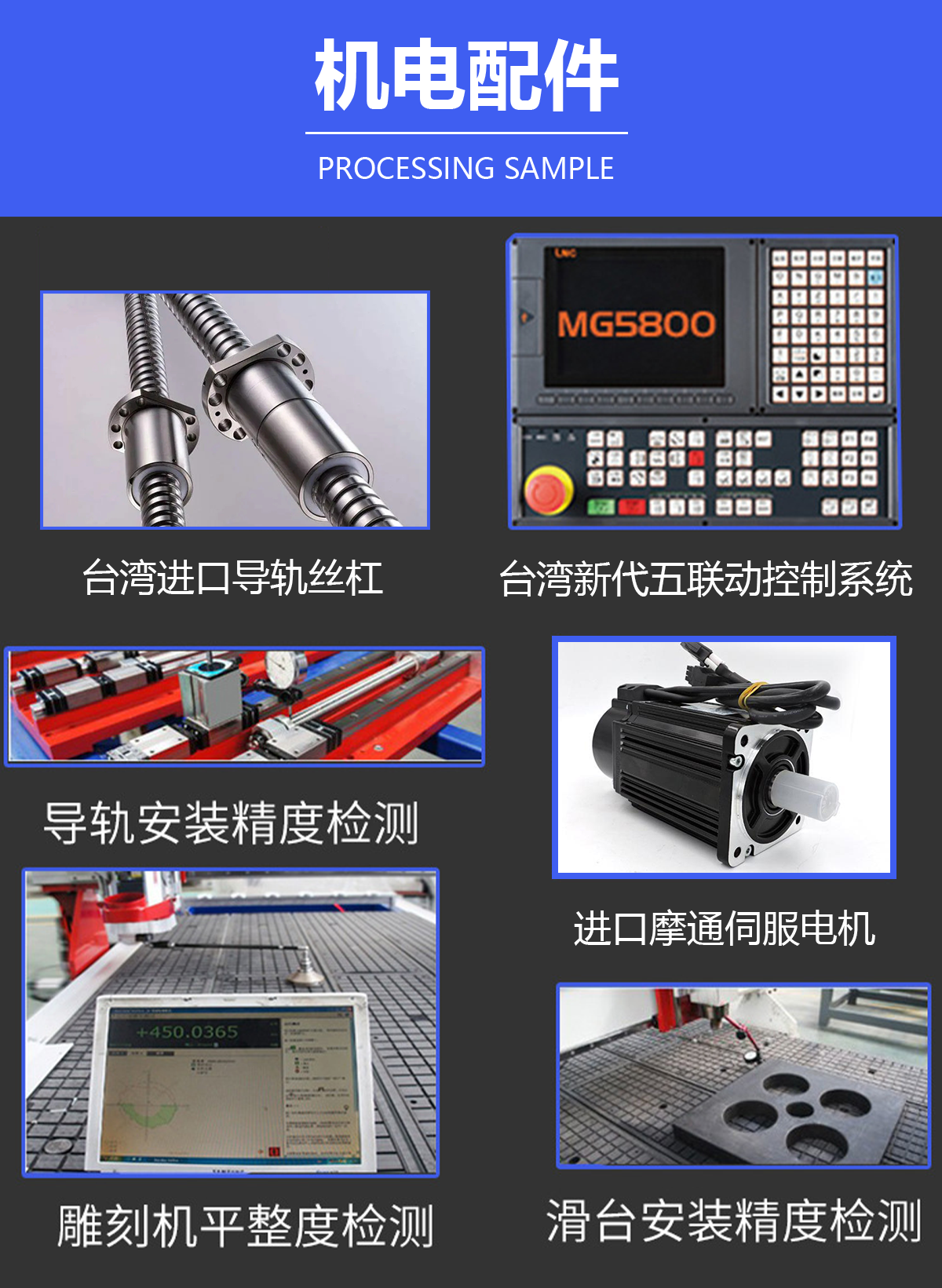

1. CNC system:The integrated drilling and tapping machine relies on an advanced numerical control system, which generates a processing program for hole processing according to the processing requirements, and processes it through computer numerical control software to control the feed system and spindle system of the machine tool to achieve automatic processing.

2. Spindle system:The spindle system is the core of the drilling and tapping machine and is responsible for providing cutting force. It usually uses an electric spindle or a mechanical spindle to achieve high-speed, high-precision machining, and is equipped with a variety of tool clamping methods to 3 adapt to tools of different diameters and lengths.

3.Feed system:The feed system is responsible for controlling the feed rate and position of the tool on the workpiece. It adopts high-precision ball screw and linear guide rail to ensure the stability and accuracy of the feed movement, and at the same time, it can also achieve fast positioning and high-speed cutting, and improve processing efficiency.

4.Cooling system:The drill and tap machine is also equipped with a cooling system for cooling the cutting area and the tool. Coolant is sprayed into the cutting area through the nozzle, taking away the cutting heat and reducing the tool temperature, while lubricating the tool and workpiece surface, reducing friction and bonding.

Application Benefits

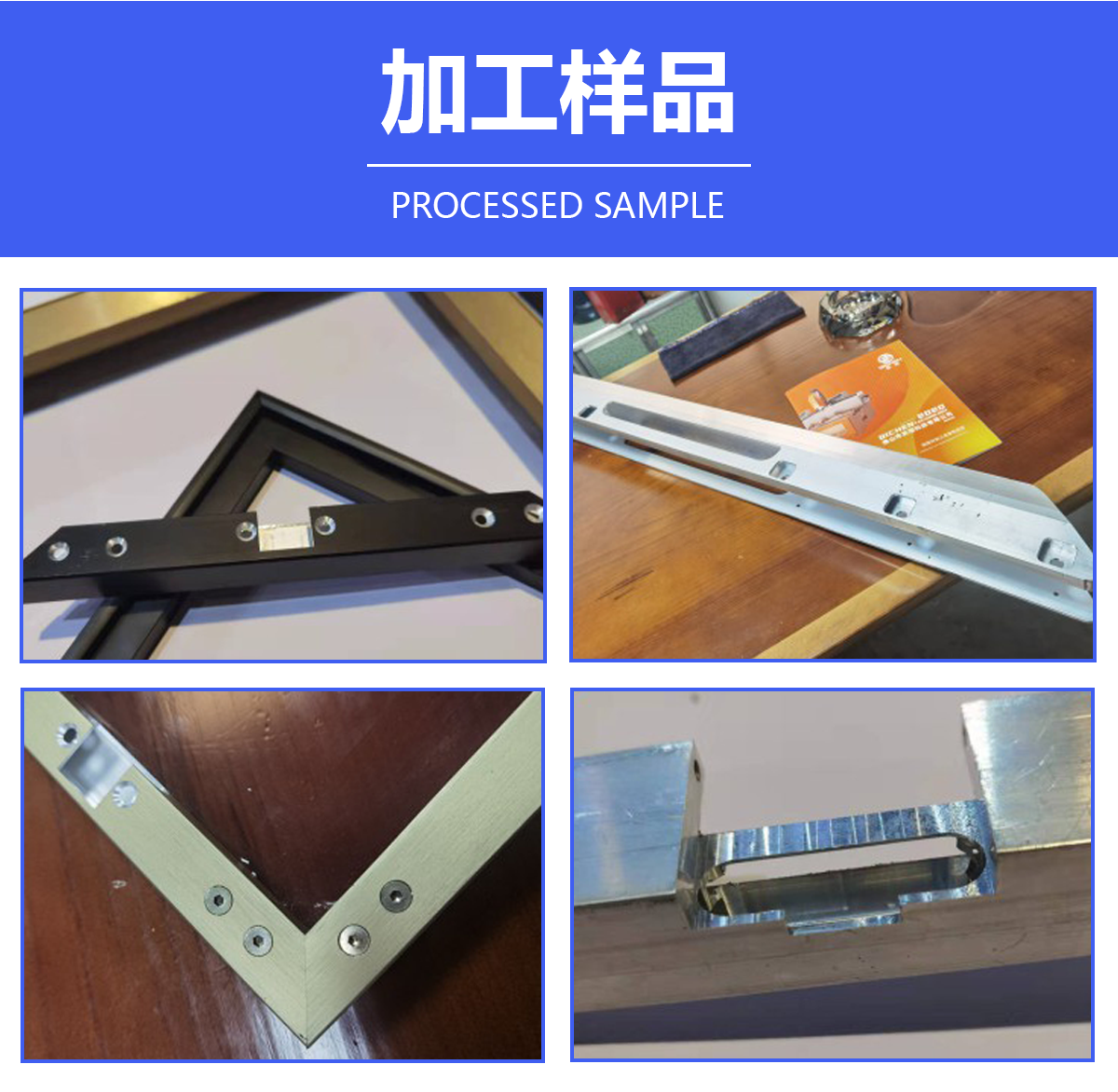

1.Efficiency:The industrial profile drilling and tapping machine can complete the drilling and tapping process at one time, which greatly improves the production efficiency. For example, in the aluminium machining industry, it can drill and tap multiple holes in a matter of seconds.

2.High precision:Using advanced control system and sensor technology, it can accurately control the drilling and tapping depth, diameter and other parameters to ensure the accuracy and quality of the machined parts.

3.flexibility:The quick-change function of the drill and tapping tool makes the machine suitable for the machining of workpieces of different sizes and models, which meets the needs of different customers.

4.stability:The rigid gantry structure is used to ensure the stability and accuracy of the machining process.

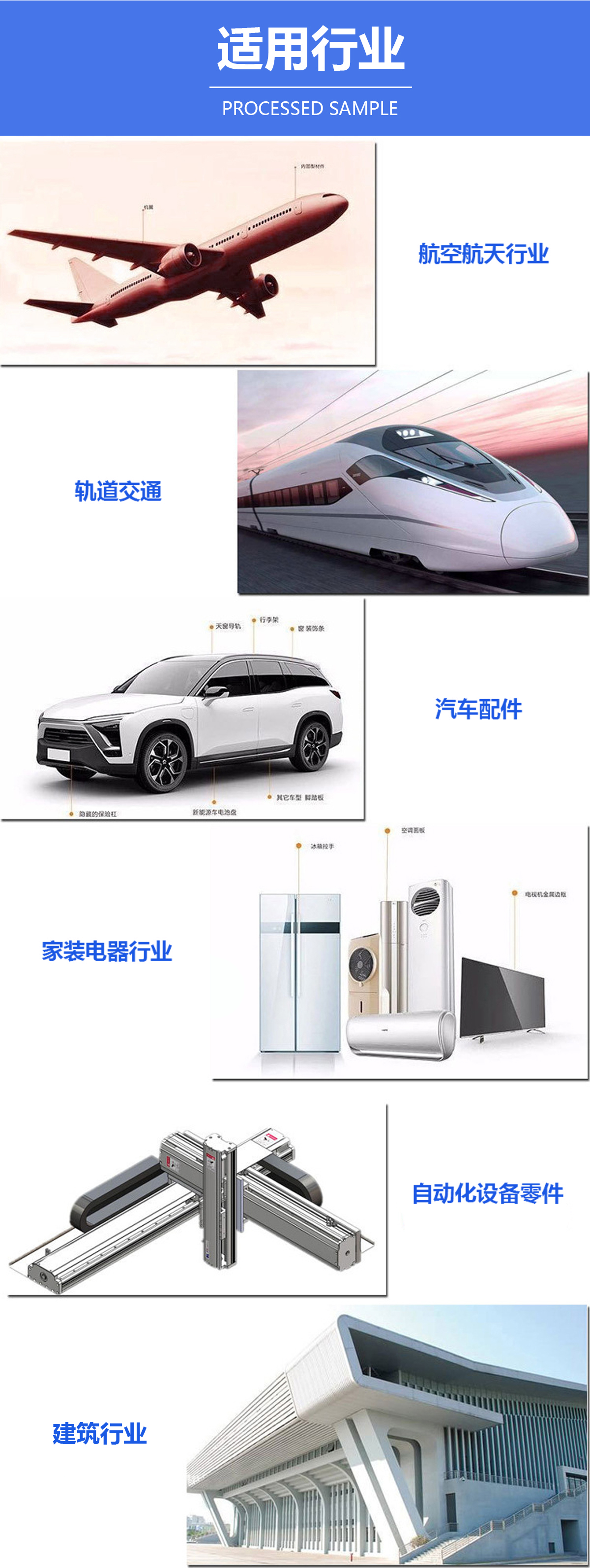

Fields of application

Industrial profile drilling and tapping machines are widely used in many fields, including but not limited to:

1.Auto parts manufacturing:In the process of automobile manufacturing, aluminum alloy materials are widely used in the manufacture of body structures and parts. The integrated drilling and tapping machine can be used for the processing of automobile door panels, roofs, chassis and other components.

2.Electronic equipment manufacturing:Aluminum alloy materials are widely used in the field of electronic equipment manufacturing due to their light weight and good thermal conductivity. The all-in-one drilling and tapping machine can be used for the processing of electronic equipment shells and parts such as mobile phones, computers, tablets, etc.

3.Architectural decoration:Aluminum alloy materials are widely used in architectural decoration, such as aluminum alloy window frames, sun rooms, etc. The integrated drilling and tapping machine can be used for the processing of aluminum alloy window frames to realize the standardized and precise production of window frames.

next page

Related products