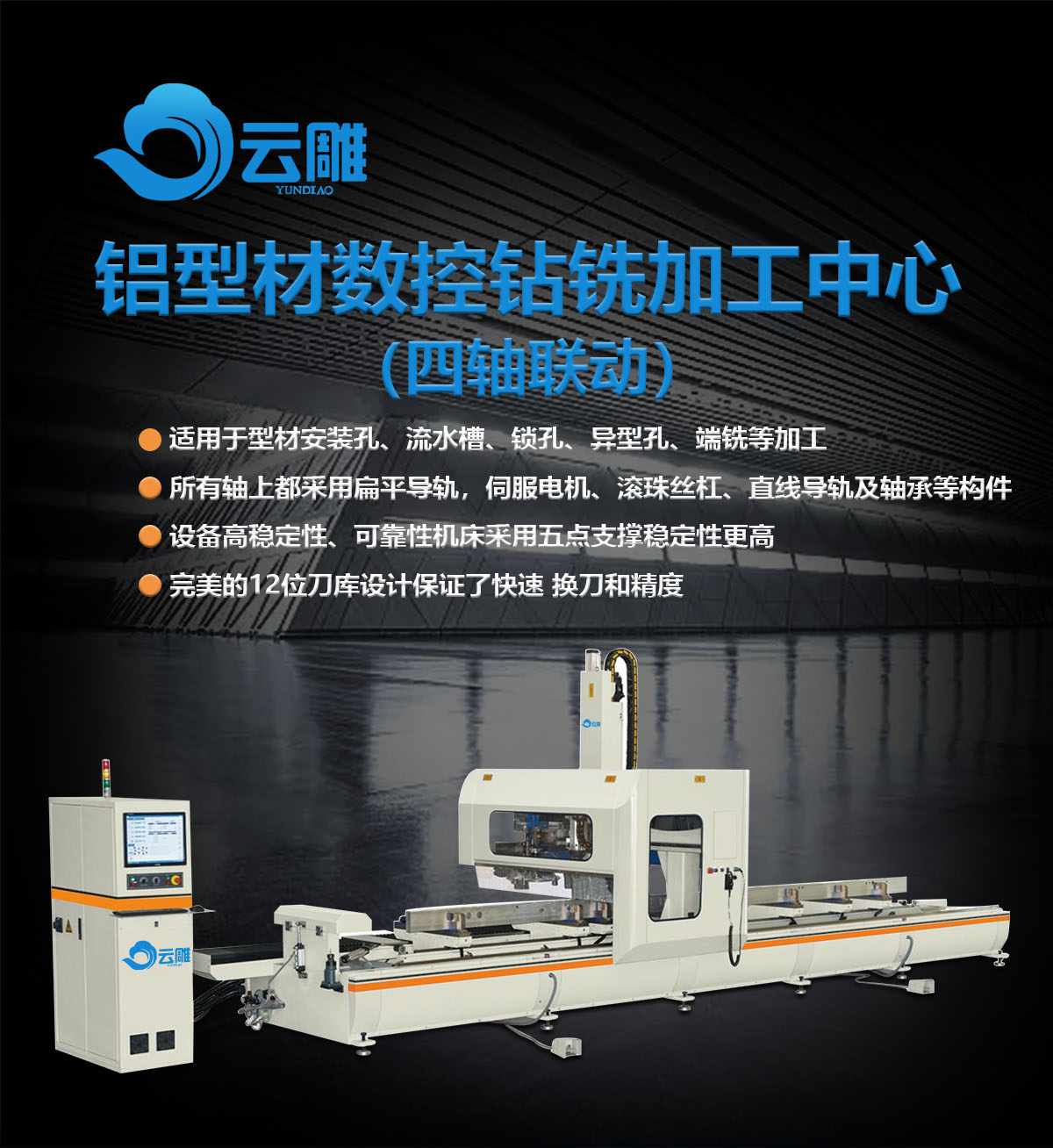

Aluminum profile CNC drilling and milling machining center (four-axis linkage)

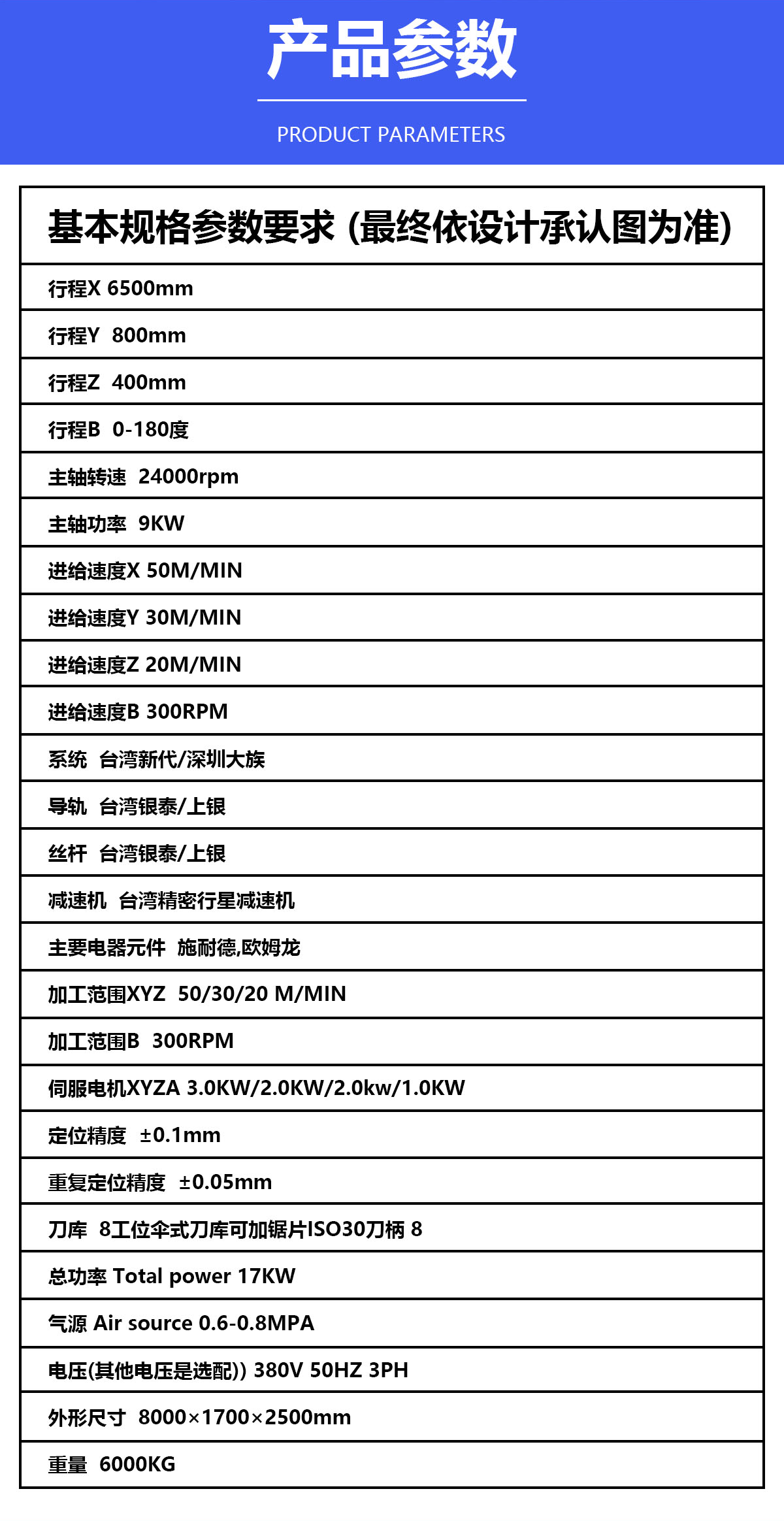

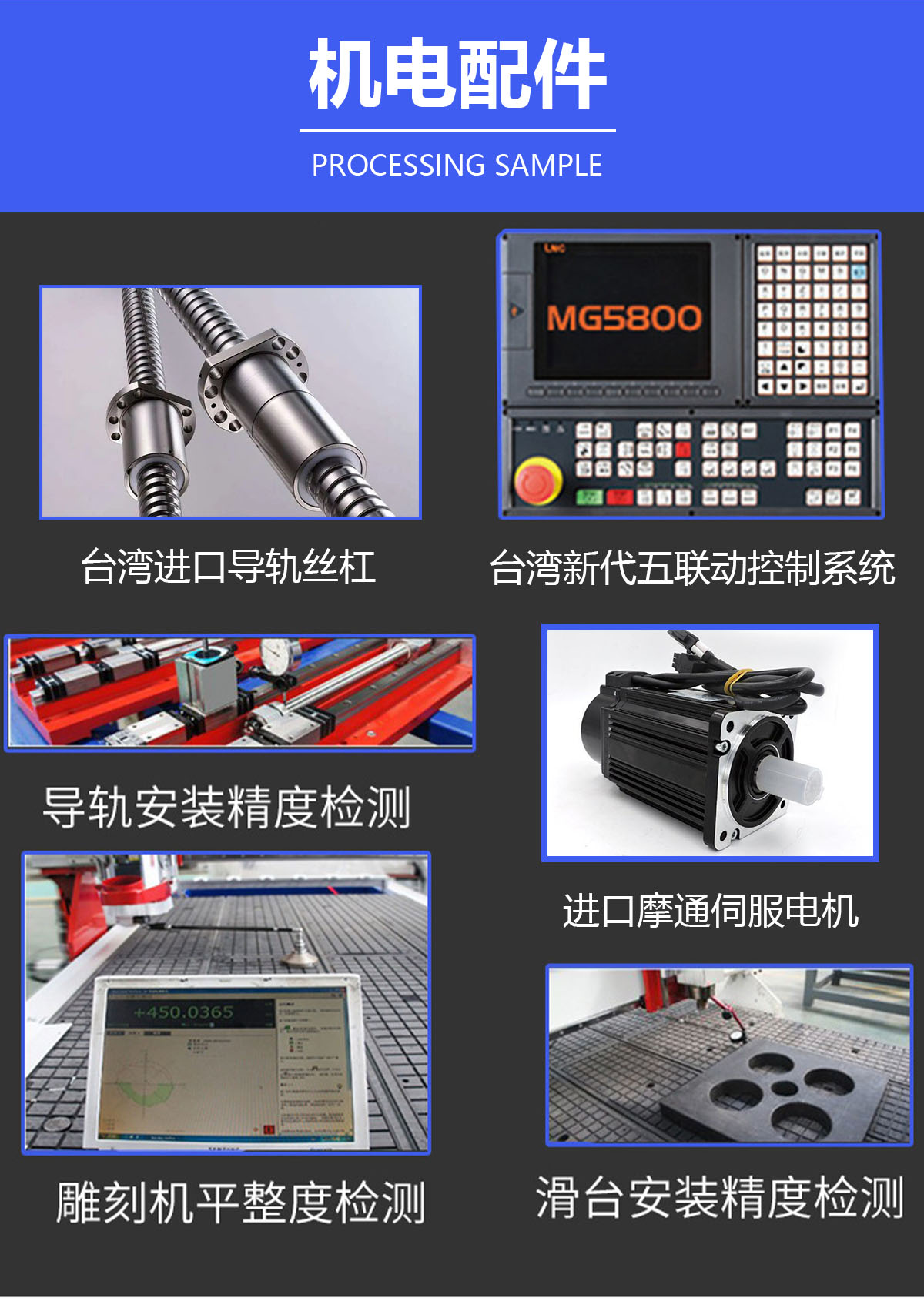

Fool-like operation: online with ERP software to realize automatic processing of code scanning; It is suitable for gantry frame structure of profile installation holes, flow grooves, lock holes, special-shaped holes, end milling and other processing processes: more stable operation; Stability and accuracy: flat guide rails are used on all axes, servo motors, ball screws, linear guide rails and bearings and other components to ensure high stability and reliability of the equipment, and the machine tool adopts five-point support for higher stability; Powerful electric spindle: This machine adopts an electric spindle with a speed of up to 24,000 revolutions per minute, which can complete the processing at any angle within 180 degrees, with extremely high work efficiency, and achieve the performance of high-speed milling, high-speed drilling and high-speed tapping; Tool magazine: 12-position tool magazine design ensures fast tool change and accuracy; Control technology: using Taiwan control system, simple and intuitive operation interface, one clamping to complete the processing of three faces; Smart fixture: Powerful software support, fixture can be placed automatically. The fixtures can be freely combined to process the workpiece, which is more convenient. Dual working area: double working area processing interactive feeding does not stop, and the efficiency is higher; Lubrication: Adopt professional minimum quantity lubrication system to improve the working environment and be more energy-saving and environmentally friendly; Protection: Humanized infrared safety protection function to protect the safety of the operator.

Product characteristics:

Category:

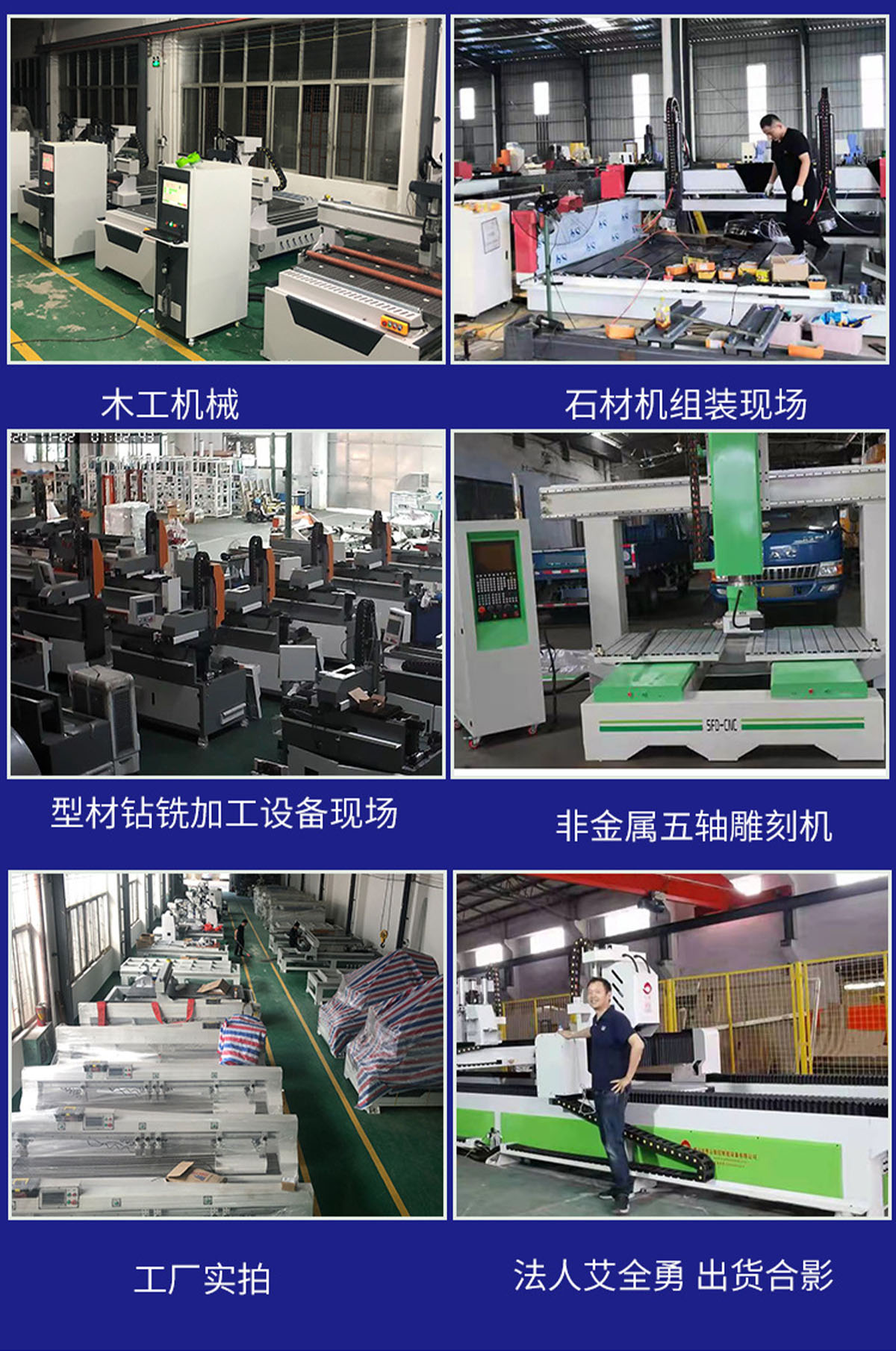

Profile processing equipment

Product attachments:

Keyword:

Aluminum profile CNC drilling and milling machining center (four-axis linkage)

contact us

Product Description

Aluminum profile CNC drilling and milling machining center (four-axis linkage) refers to the machine tool can control and coordinate the movement of four axes (usually X, Y, Z axis plus a rotary axis A, or B axis or C axis) at the same time during the machining process to achieve more complex machining needs. This machine combines CNC technology, drilling and milling functions to process aluminum profiles efficiently and precisely.

主要特点

1.High precision:Advanced numerical control system and servo motor are used to cooperate with high-precision transmission components (such as high-precision ball screws, high-precision helical gears, etc.) to ensure machining accuracy.

2.High efficiency:The four-axis linkage design enables the machine tool to process in multiple directions at the same time, which greatly improves the processing efficiency.

3.flexibility:According to different processing needs, the processing G-code can be automatically converted or manually entered by programming software to realize the processing of various complex shapes and structures.

4.High degree of automation:Some models are equipped with an automatic tool change system, which can automatically change the tool according to the processing needs, reduce manual intervention, and improve production efficiency and processing quality.

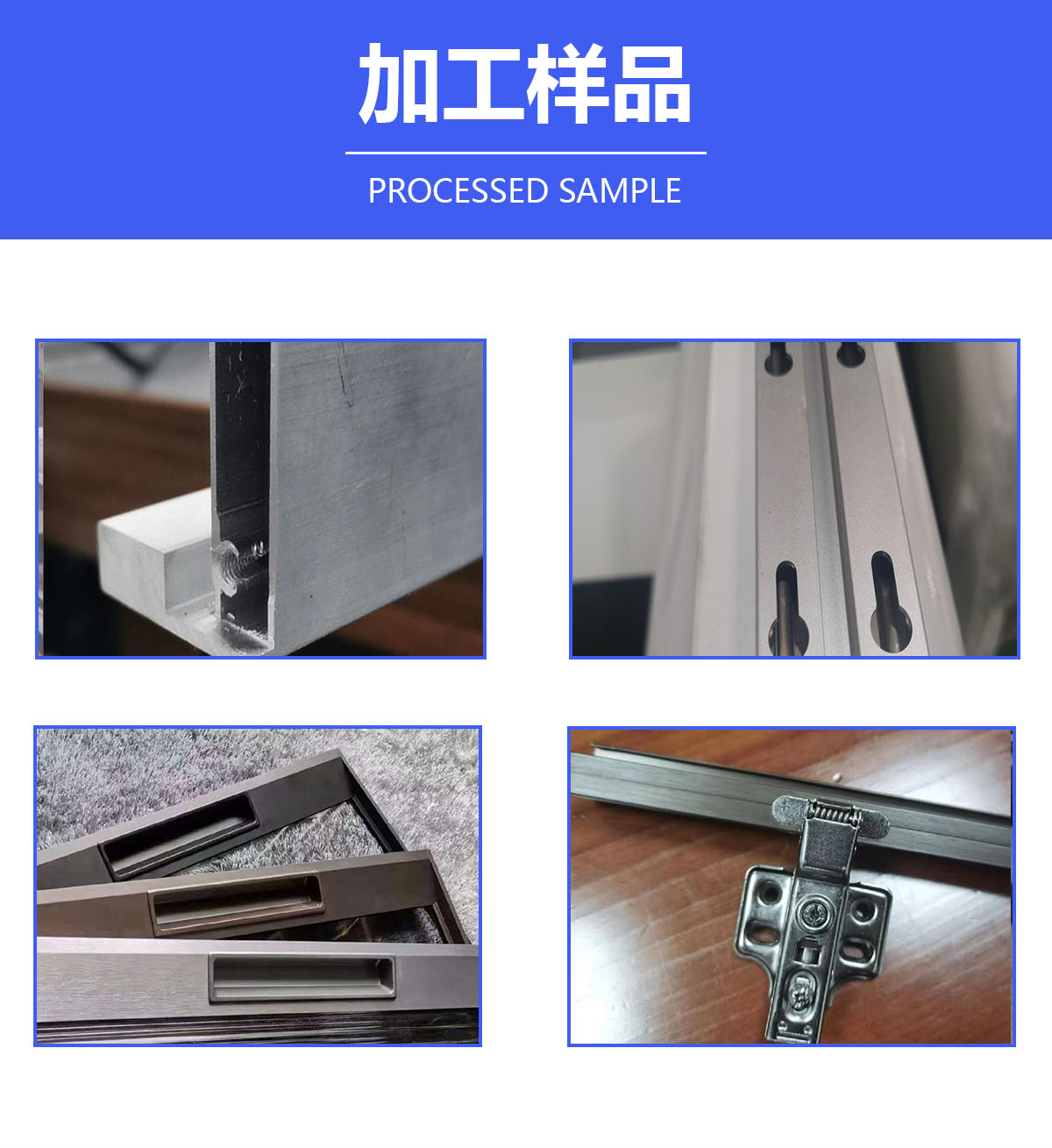

5.Safe and reliable:The equipment adopts an open protective cover to prevent aluminum chips from flying out, ensuring the safety of personnel and a clean environment. At the same time, the bed and transmission parts are specially treated to ensure long-term accuracy and reliability.Aluminum profile CNC drilling and milling machining center (four-axis linkage) is widely used in aluminum alloy doors and windows, curtain walls, furniture, automobiles, aerospace and other fields of aluminum profile processing. It can process round holes, slot holes, key holes, special-shaped holes, etc. of aluminum profiles, as well as milling, chamfering and other processes of aluminum profiles.

Related products