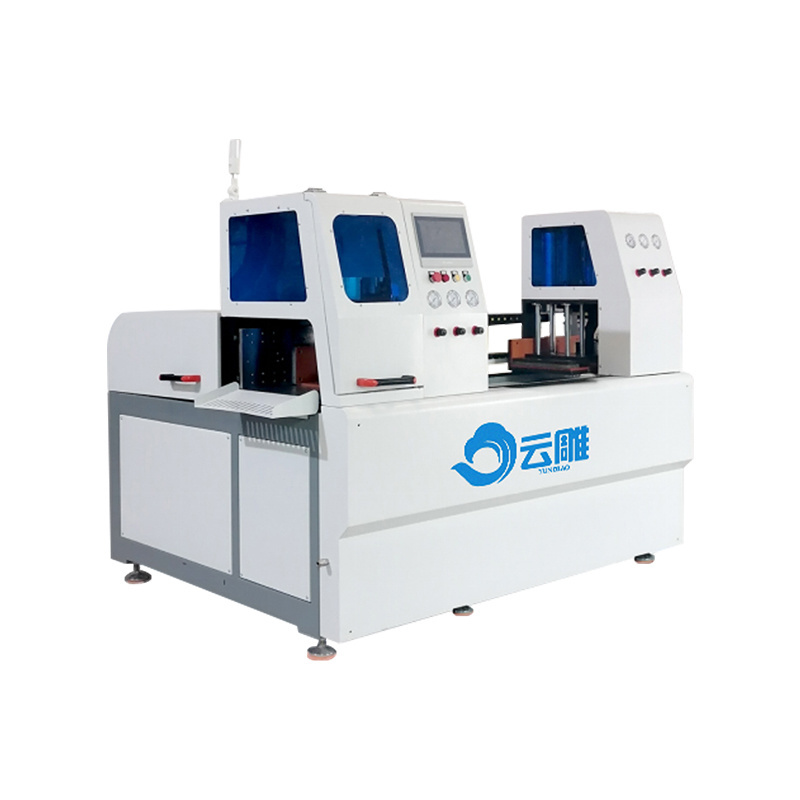

Sheet metal drilling and tapping machining center

Yundiao metal plate machining center, is a set of drilling and milling in one of the machining center equipment, widely used in aluminum alloy plate, copper and steel plate and many other materials, the equipment processing large plate is convenient and fast, such as new energy vehicle battery chassis, casting mold finishing, plate drilling and milling and other functional efficiency is significant, replacing the traditional machining center, efficiency doubled

Product characteristics:

Category:

Profile processing equipment

Product attachments:

Keyword:

Sheet metal drilling and tapping machining center

contact us

Product Description

The metal plate drilling and tapping machining center integrates a variety of processing functions such as cutting, drilling, tapping, etc., and realizes automatic processing through CNC technology. It is particularly suitable for the processing of sheet metal and can efficiently and precisely complete the machining tasks of various complex shapes. It is an advanced CNC machine tool, which is mainly used for precision machining of metal sheets.

Key features:

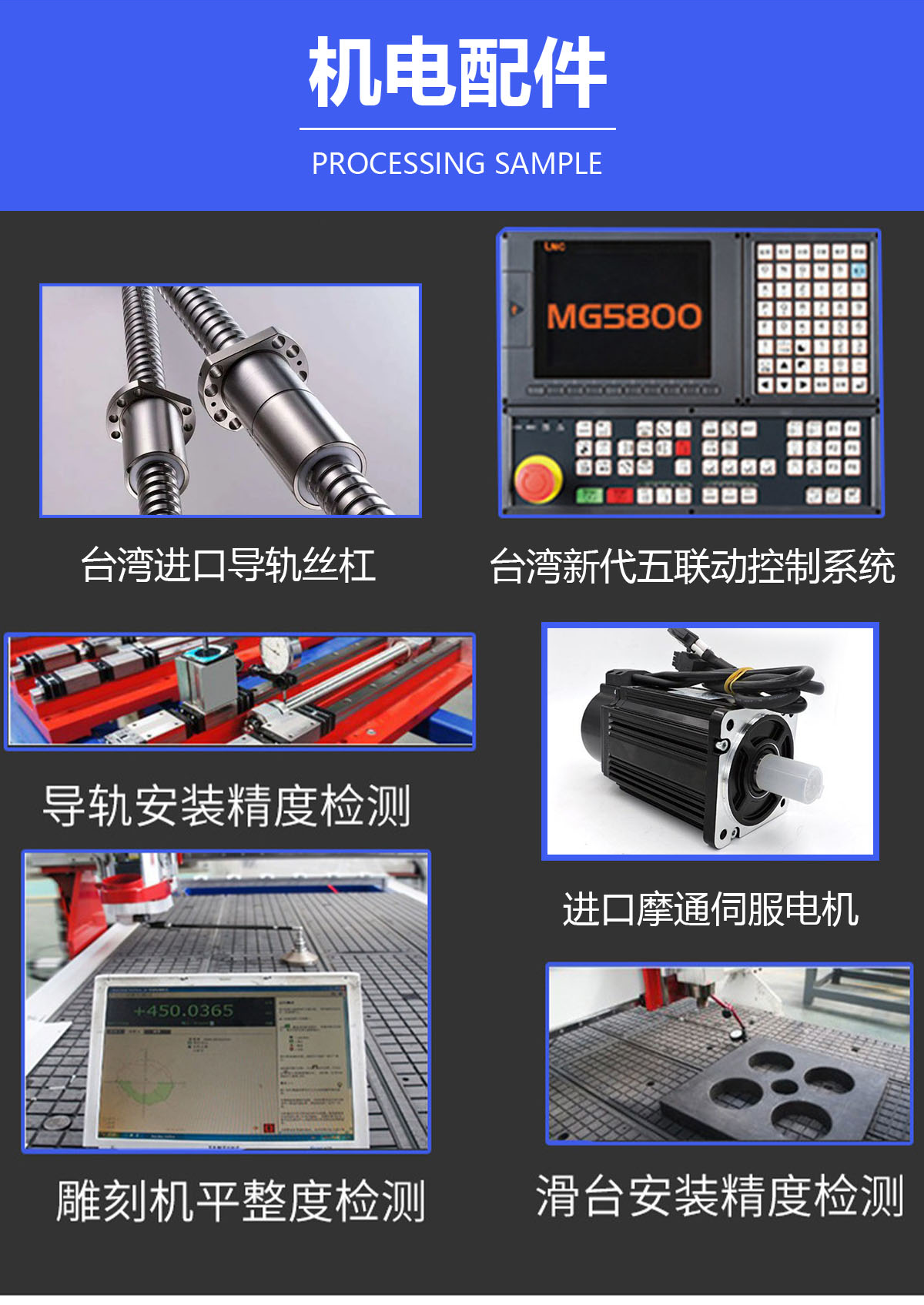

1.High precision:The sheet metal drilling and tapping machining center adopts high-precision transmission components and numerical control system, which can ensure that the machining accuracy reaches the micron level. This is essential for sheet metal that requires high-precision machining.

2.High efficiency:The equipment has a high-speed spindle and high-precision positioning function, which can quickly complete the processing task and improve production efficiency. At the same time, the automatic tool change system and the fast-moving function further reduce the machining time.

3.flexibility:The sheet metal drilling and tapping machining center can be programmed and adjusted according to different processing needs, and can process a variety of complex shapes and structures of metal sheets. In addition, it can also choose different tools and machining parameters according to the machining requirements to meet different machining needs.

4.High degree of automation:The equipment is usually equipped with an automatic loading and unloading system and an automatic tool change system, which can realize automatic processing, reduce manual intervention, and improve production efficiency and processing quality.

5.Compact structure:Compared with the traditional vertical machining center, the sheet metal drilling and tapping machining center has a smaller footprint and processing stroke, and the structure is more compact and flexible, which is convenient for processing operations in a limited space.

Sheet metal drilling and tapping machining centers are widely used in automobile manufacturing, aerospace, electronic equipment, precision instrument manufacturing and other fields. It is capable of machining a variety of high-quality sheet metal parts, such as engine blocks, transmission housings, precision molds, etc.

Related products