Small wood mold engraving machine

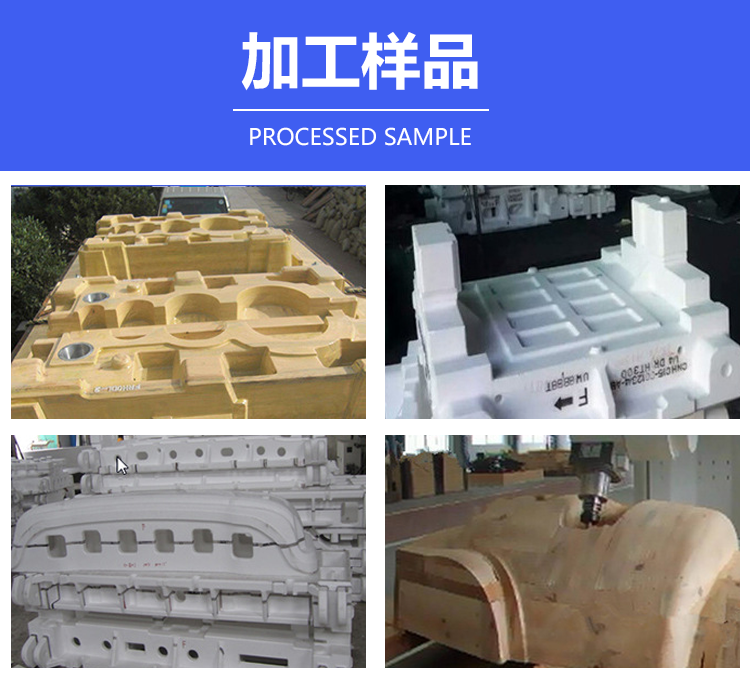

Small three-axis non-metallic mold engraving machine is a kind of engraving machine equipment specially used for processing non-metallic materials. Suitable for all kinds of non-metallic materials, such as wood, acrylic, PVC, plastic, etc. These materials may require different tools and cutting data for engraving. In addition to the basic engraving functions, it may also be equipped with other functions such as cutting, punching, milling, etc., to meet the processing needs of different non-metallic materials. The operator interface and control system may need to be more intuitive and easy to use so that the operator can get up to speed quickly. Reduce personnel training time.

Product characteristics:

Category:

Three axis engraving machine

Product attachments:

Keyword:

Small wood mold engraving machine

contact us

Product Description

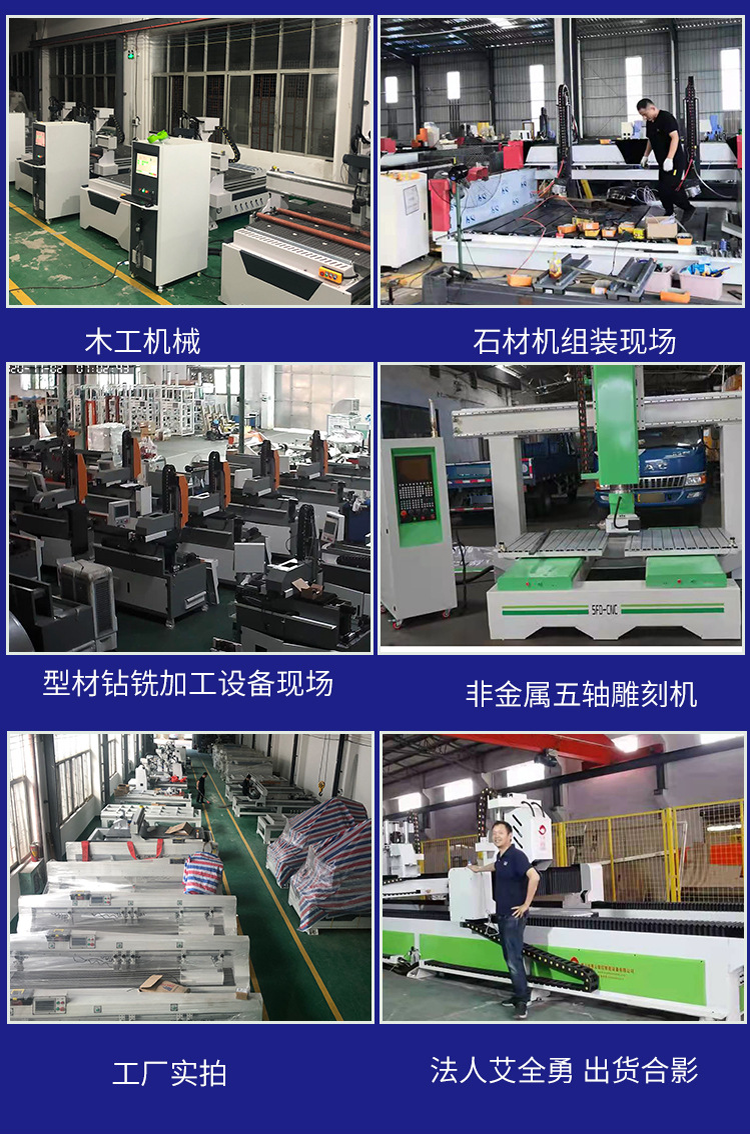

Small wood mold engraving machine is a kind of equipment specially used for wood mold carving, usually with a small body size, suitable for use in small and medium-sized factories or studios. It adopts advanced numerical control technology, controls the engraving path through computer programming, and realizes automatic engraving operations. It has the characteristics of high precision, high efficiency and easy operation, and is widely used in woodworking industry, furniture manufacturing, decoration and other fields.

Key features:

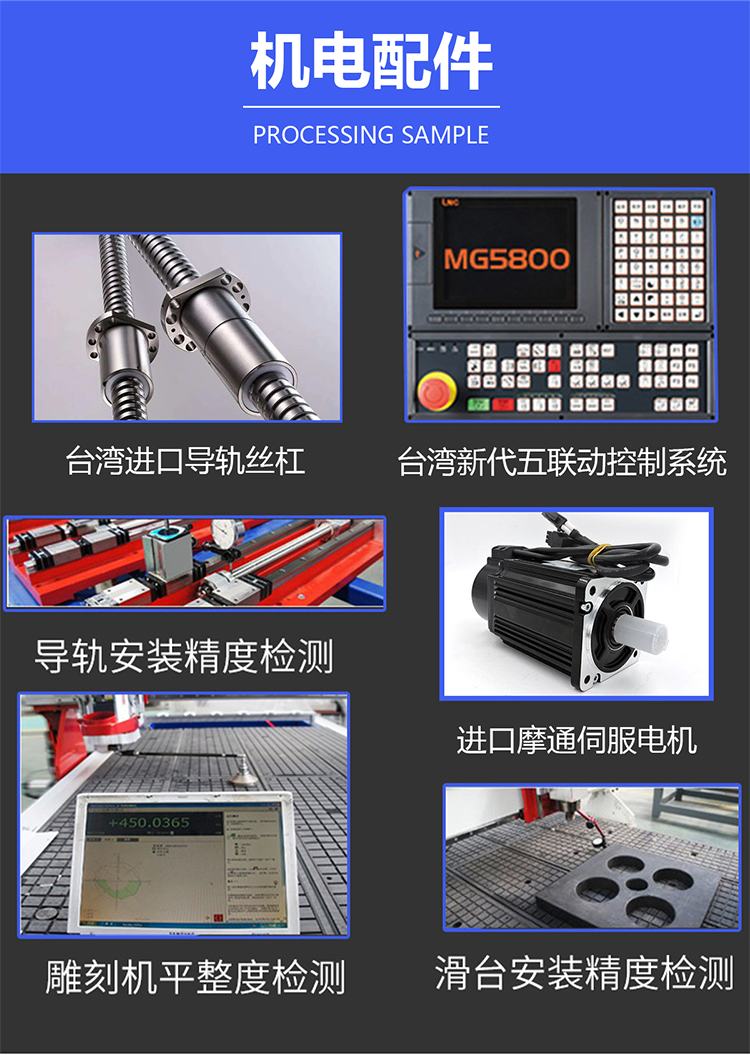

1.High precision:The small wood mold engraving machine adopts a precision servo motor and transmission system to meet the needs of high-precision mold engraving.

2.High efficiency:The equipment has high-speed engraving capacity, which can complete a large number of engraving tasks in a short time and improve production efficiency.

3.Versatility:In addition to wood, it can also be carved with a variety of materials such as acrylic, PVC board, two-color plate, etc., to meet the needs of different industries.

4.Easy to operate:The user-friendly design, intuitive user interface and easy-to-learn software enable operators to get up and running quickly.

Cloud carving purchase suggestions

1.Define your needs:Clarify your processing needs and material type before making a purchase so that you can choose the right equipment model.

2.Compare performance:Compare the performance, accuracy, efficiency and other indicators of equipment of different brands and models, and choose cost-effective products.

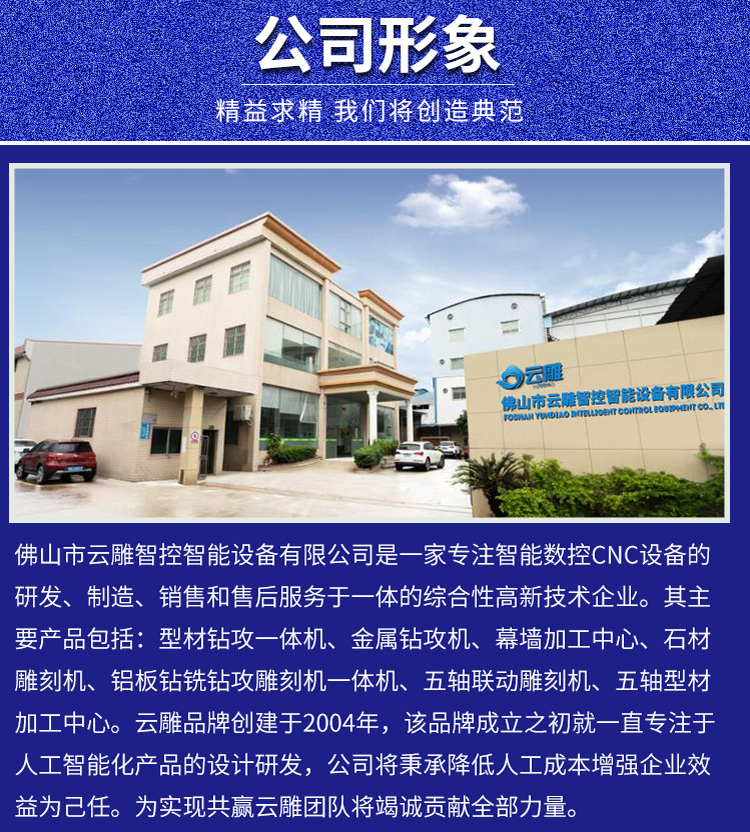

3.Find the source manufacturer:Understand the manufacturer's production strength, after-sales service, etc., and choose a reputable source manufacturer to cooperate.

4.On-site commissioning:If conditions permit, carry out on-site test operation to experience the performance and convenience of the equipment first-hand.When selecting and using, factors such as equipment performance, application field and market demand should be fully considered to achieve the best economic and social benefits.

last page

Related products