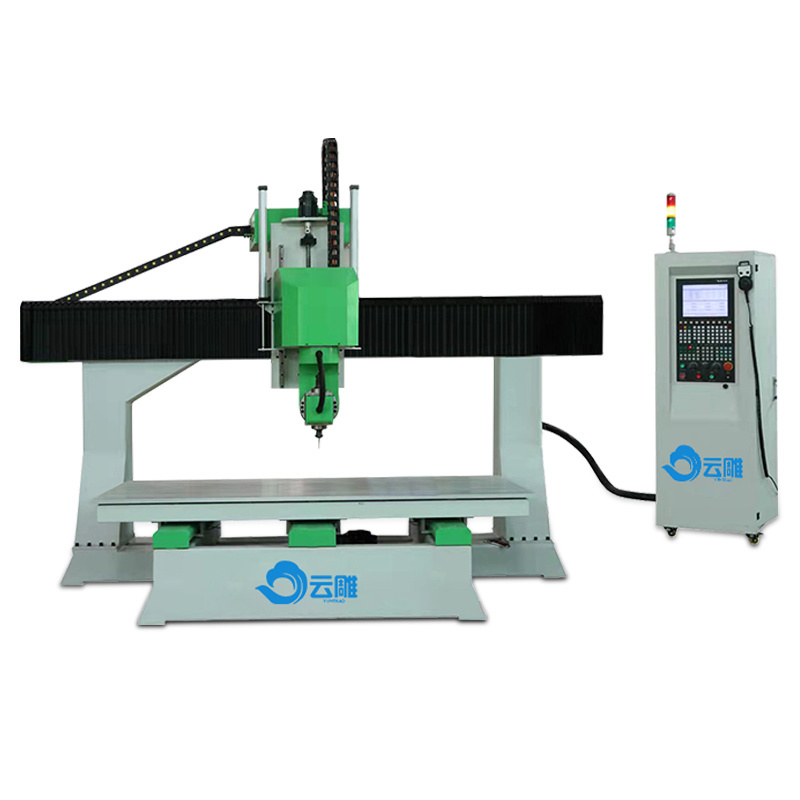

Large-scale five-axis ancient building cutting and engraving center

The equipment adopts Taiwan's new generation CNC system, which has the characteristics of automatic tool change, five-axis linkage, RTCP support, and tip follow-up. The machining width is 3 meters 5, the processing length is 9 meters, and it is equipped with a saw blade tool changer and eight tool magazines for tool holder tool change

Product characteristics:

Category:

Five axis engraving machine

Product attachments:

Keyword:

Large-scale five-axis ancient building cutting and engraving center

contact us

Product Description

|

Model |

YD-1325 |

YD-1530 |

YD-2030 |

|

Working area |

1300*2500mm |

1500*3000mm |

2000*3000mm |

|

Z feeding |

400mm (option max height 600mm) |

||

|

Frame structure |

Steel casting-welding |

||

|

Type of table cover |

Vacuum table with T-slot |

||

|

Vacuum pump |

7.5kw air cooling |

||

|

Z axis transmission |

Ball screw and 25 square guide rails |

||

|

X Y axis transmission |

25# square guide rails + Helical rack |

||

|

Max. Rapid Travel Rate |

45000mm/min |

||

|

Max. Working Speed |

30000mm/min |

||

|

Command Code |

G code * .u00 * .mmg * .plt |

||

|

Operating voltage |

AC 380V/50Hz |

||

|

Spindle power |

HQD atc 9.0 KW |

||

|

Spindle rotate |

Left and right 180 degree |

||

|

Tool Magazine |

specification |

||

|

Type of cooling |

Air cooling |

||

|

Spindle Speeds |

0-24000rpm/min |

||

|

Drive motor type |

Syntec 1000w servo motor and driver |

||

|

operating system |

Taiwan SYNTEC 60WE bus control |

||

|

Dust Collector |

3kw with double bags |

||

|

Lubrication system |

Automatic |

||

|

Supported software |

Artcam software, Type3 software |

||

|

Operating conditions |

Humidity: 30% -75%, temperature: 15 - 45 degree |

||

|

Warranty |

Two years |

||

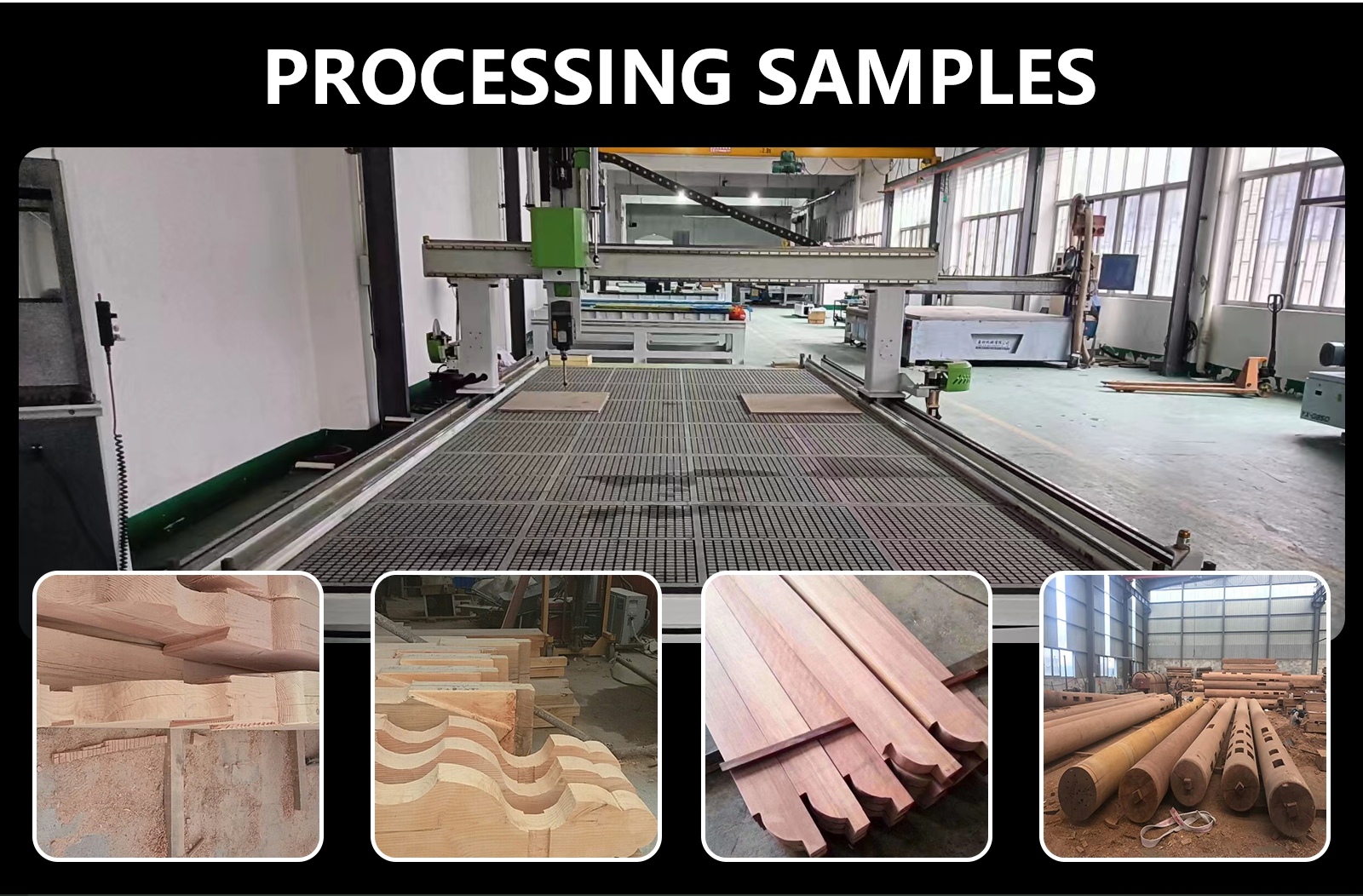

Large five-axis wood mold engraving cutting machine is a kind of high-precision and high-efficiency CNC equipment specially designed for wood processing, which is widely used in furniture manufacturing, large-scale wood cutting and cutting, Chinese construction, wooden house construction and other fields. Combined with 5-axis linkage technology and an advanced CNC system, complex engraving and cutting tasks can be realized in three-dimensional space. It is suitable for all types of wood, including solid wood, wood-based panels, etc., and can meet different processing needs.

Key features

1.Five-axis linkage technology:

The five-axis differential compensation algorithm and RTCP five-axis fast differential compensation technology are used to realize the real five-axis linkage machining.

It supports the tip following function to ensure that the tool maintains the best contact with the surface of the workpiece during the machining process and improves the machining accuracy.

2.High-precision machining:

Equipped with high-precision servo motors, ball screws and guide rails and other transmission components to ensure that the machining accuracy reaches a high level.

The repeated positioning accuracy and machining accuracy can meet the requirements of high-precision machining.

3.Efficient production:

High-speed spindles and advanced CNC systems support fast machining and improve production efficiency.

It supports automatic tool change and automatic measurement functions to reduce manual intervention and improve the degree of production automation.

4.Versatility:

It is suitable for all kinds of wood carving, cutting, cutting and other processing tasks.

Equipment with different specifications and configurations can be customized according to customer needs.

5.Stable and durable:

The overall steel structure design is adopted, and the bed is thick to ensure that it will not be deformed for long-term use.

The transmission parts are made of high-quality materials to ensure stability and durability for long-term use.

last page

Related products