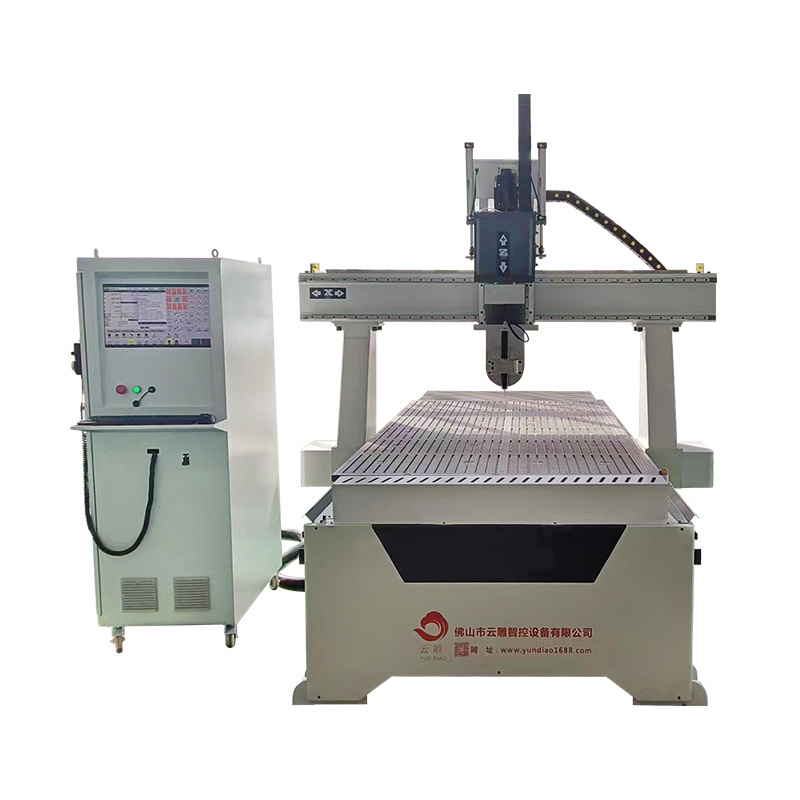

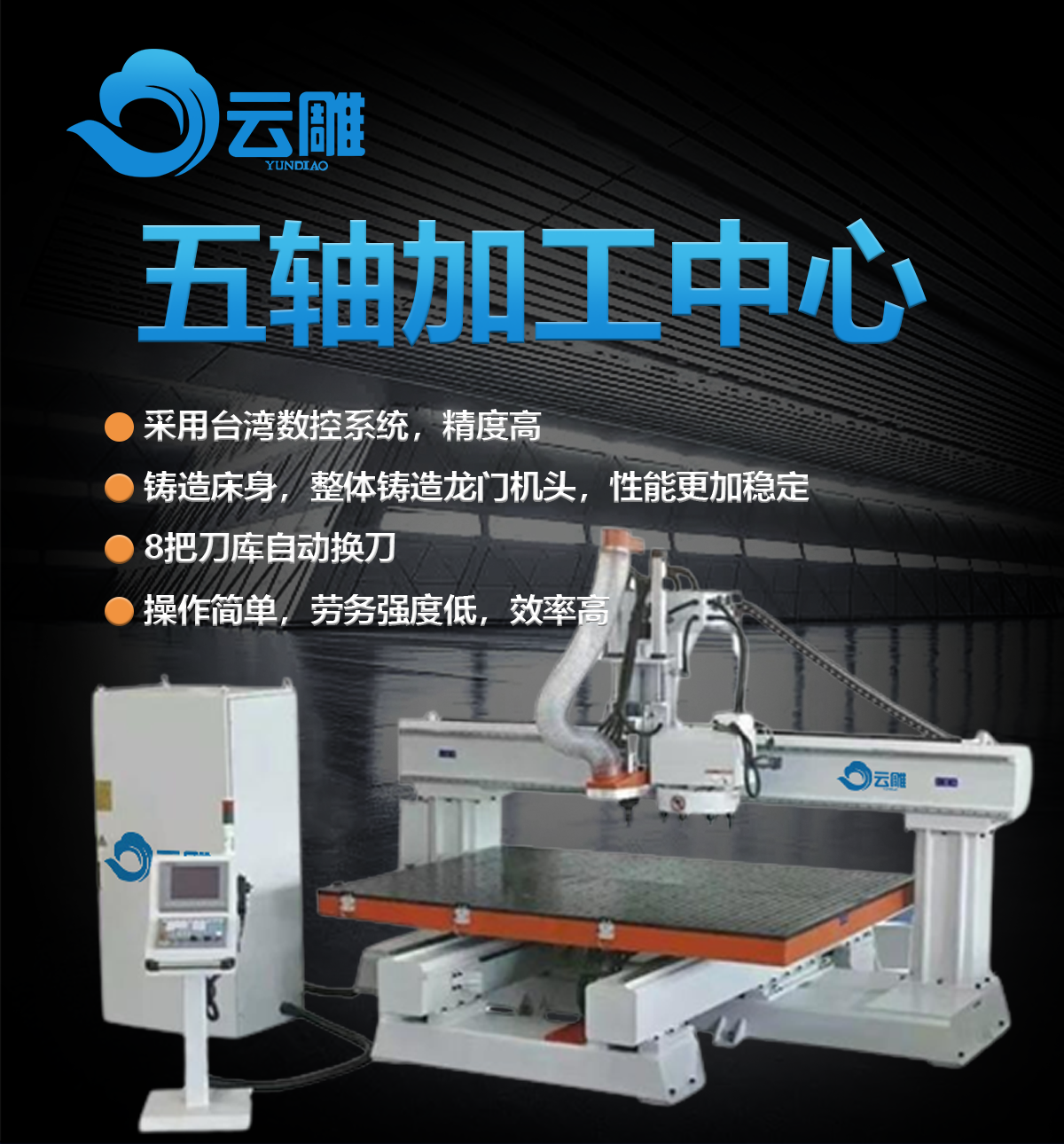

Non-metallic five-axis machining center

Cloud carving non-metal five-axis machining center, whether it is foam carving, or woodworking carving, the efficiency is very powerful, the product adopts Taiwan new generation CNC system, Japan Yaskawa bus servo, Japan Sumitomo RV reducer, making the performance more excellent

Product characteristics:

Category:

Five axis engraving machine

Product attachments:

Keyword:

Non-metallic five-axis machining center

contact us

Product Description

Cloud carving non-metallic five-axis engraving machine is a high-precision CNC equipment specially designed for the processing of non-metallic materials, by controlling the movement of X, Y, Z axes and the rotation around these three axes, to achieve accurate engraving and cutting of non-metallic materials. Its five-axis linkage technology makes the machining process more flexible and efficient, and can meet the machining needs of complex shapes and structures. It is widely used in architectural models, bathtub molds, furniture, handicrafts and other fields.

Key features

1. Five-axis linkage technology:

The five-axis differential compensation algorithm and RTCP five-axis rapid differential compensation technology are used to truly realize the five-axis linkage and reduce the positioning time and error in the machining process.

It supports the tip following function to ensure that the tool always maintains the best contact with the surface of the workpiece during the machining process, improving the machining accuracy and efficiency.

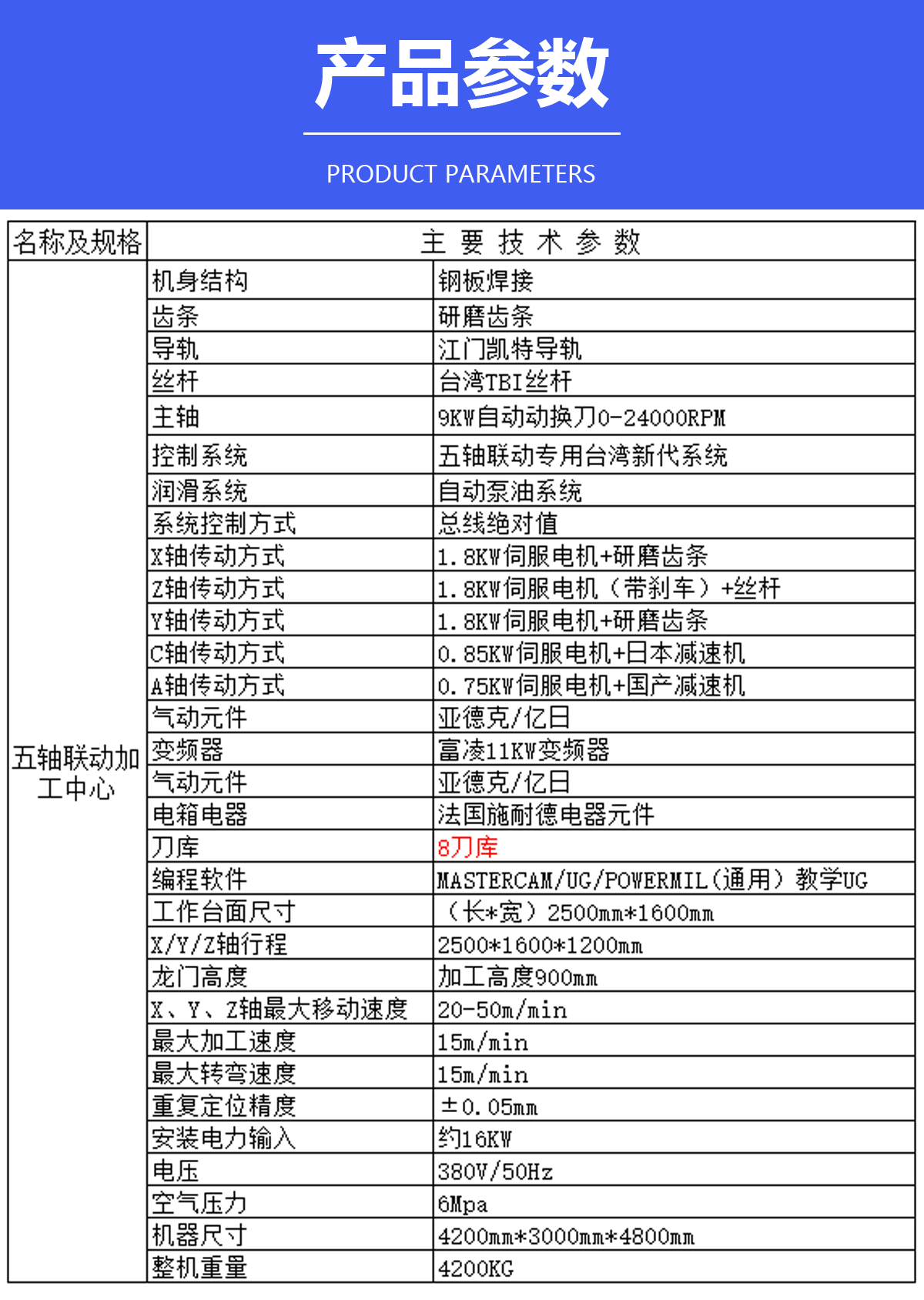

2. High-precision machining:

The accuracy error of the machine tool is controlled within plus or minus 0.03mm, and the repeated positioning accuracy reaches 0.05mm to ensure the fineness and consistency of the processed products.

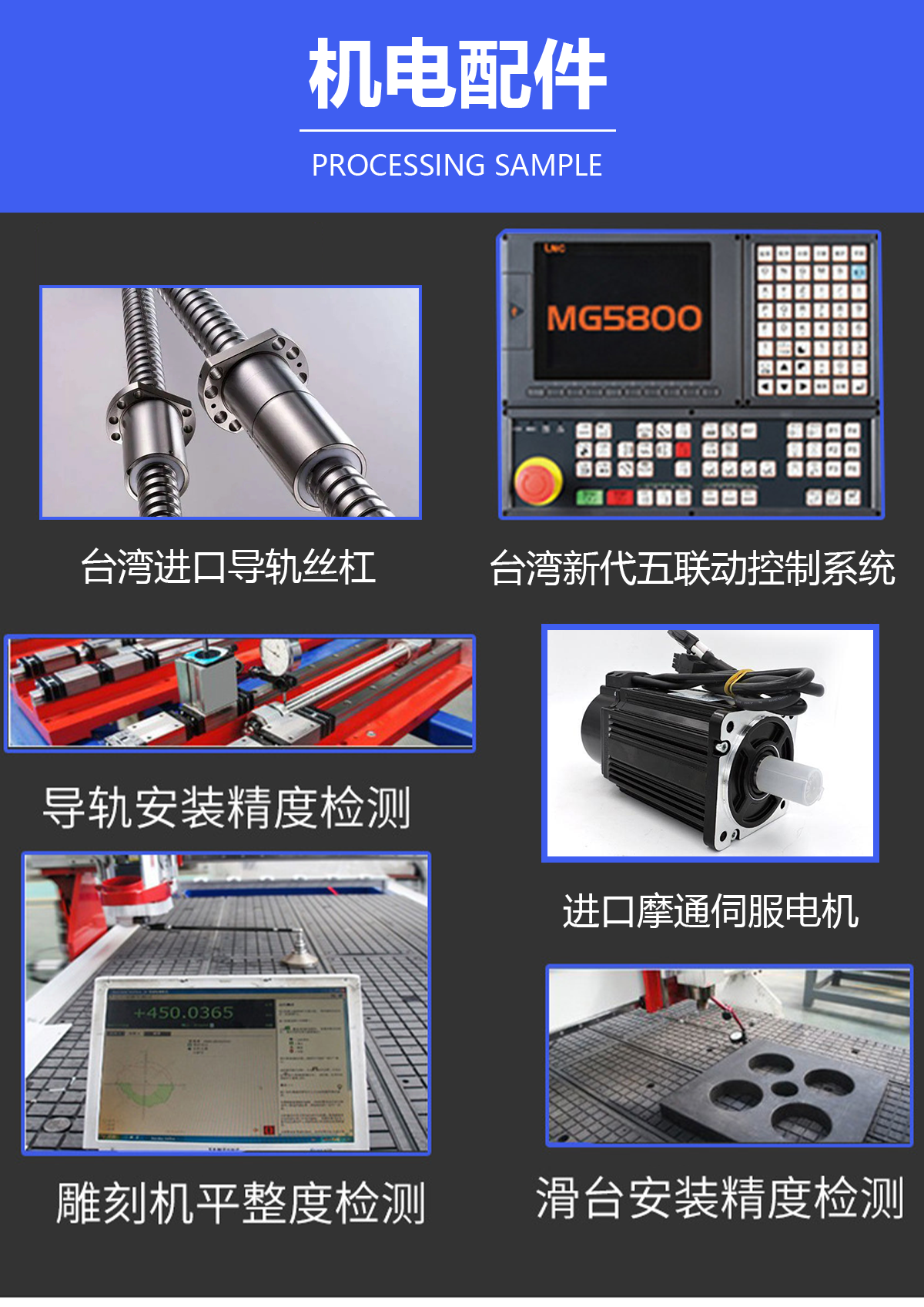

Equipped with high-quality spindles, transmission systems and servo motors to ensure the stability and precision of the machining process.

3. High-efficiency production:

The high-speed spindle and advanced differential compensation system enable a significant increase in machining speed while maintaining high accuracy.

It supports automatic tool change, automatic measurement and other functions to reduce manual intervention and improve production efficiency.

4. Durable and stable:

The structure of the machine tool adopts the gantry bed structure, which is welded and formed by the square steel plate and annealed to ensure sufficient strength and stability.

The workbench adopts a casting structure, a beam cast steel structure, a column is welded and formed, and the machining parts required for the overall bed are precision processed by a CNC machining center to ensure that it is not deformed for long-term use.

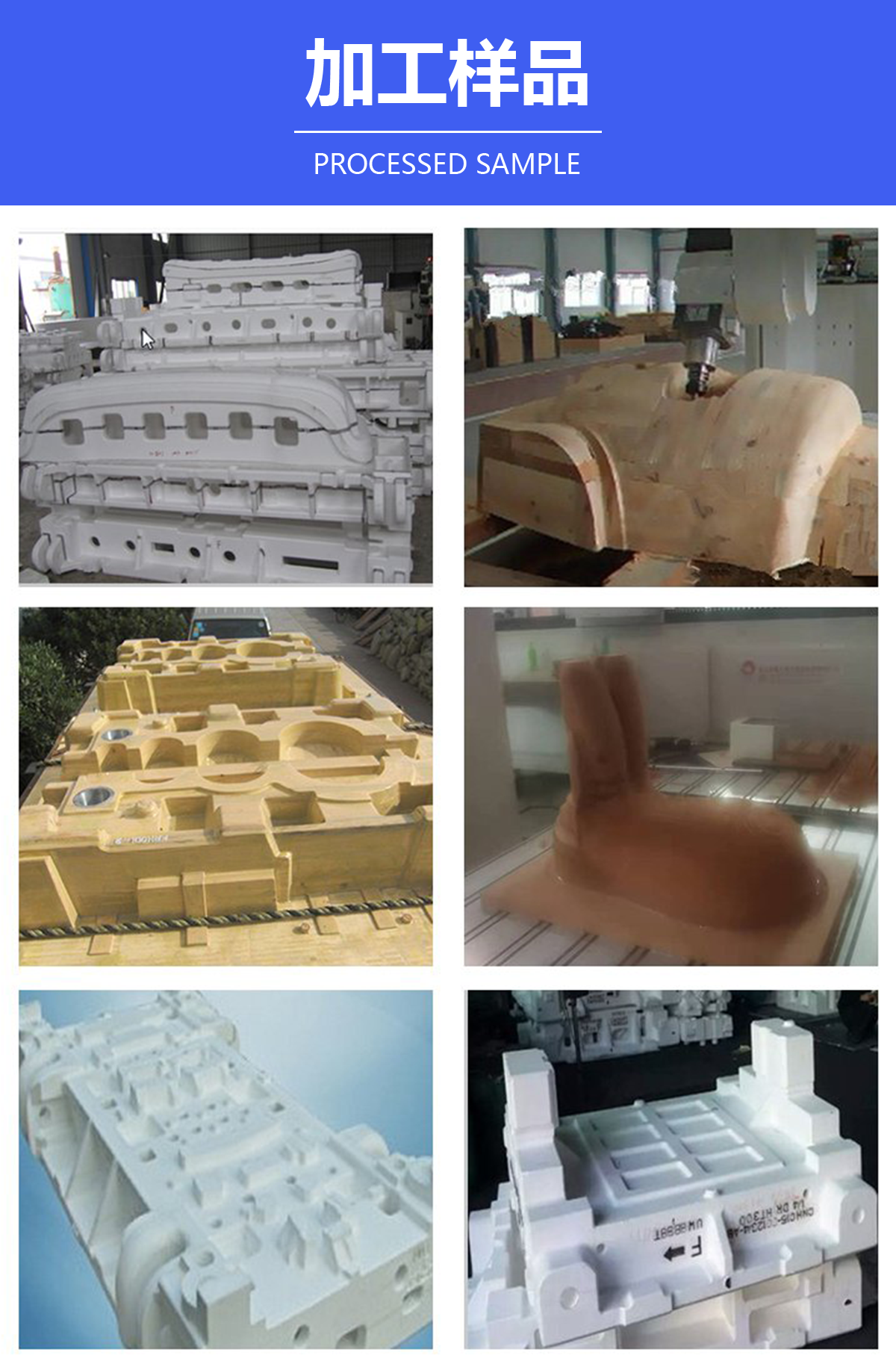

5. Wide range of application:

It can process a variety of non-metallic materials such as Styrofoam (EPS), substitute wood, resin, gypsum, oil sludge, wood and non-metallic carbonized mixture.

It is widely used in architectural model making, bathtub mold processing, furniture manufacturing, handicraft carving and other fields.

With its high precision, high efficiency, durable and stable characteristics and wide range of applications, the engraving machine has shown strong competitiveness in the field of non-metallic material processing.

Related products