Five-axis blister cutting machining center

The equipment is also widely used in large-scale automobile molds, foam plastic molds, lost foam carving, curved furniture, tables and chairs engraving and cutting processing, cartoon character statues, garden three-dimensional sculptures, casting molds, wood molds, plastic molds, luggage molds and other high-precision three-dimensional products processing, as well as ceramic mold development and other fields.

Product characteristics:

Category:

Five axis engraving machine

Product attachments:

Keyword:

Five-axis blister cutting machining center

contact us

Product Description

Yundiao composite material processing center product description

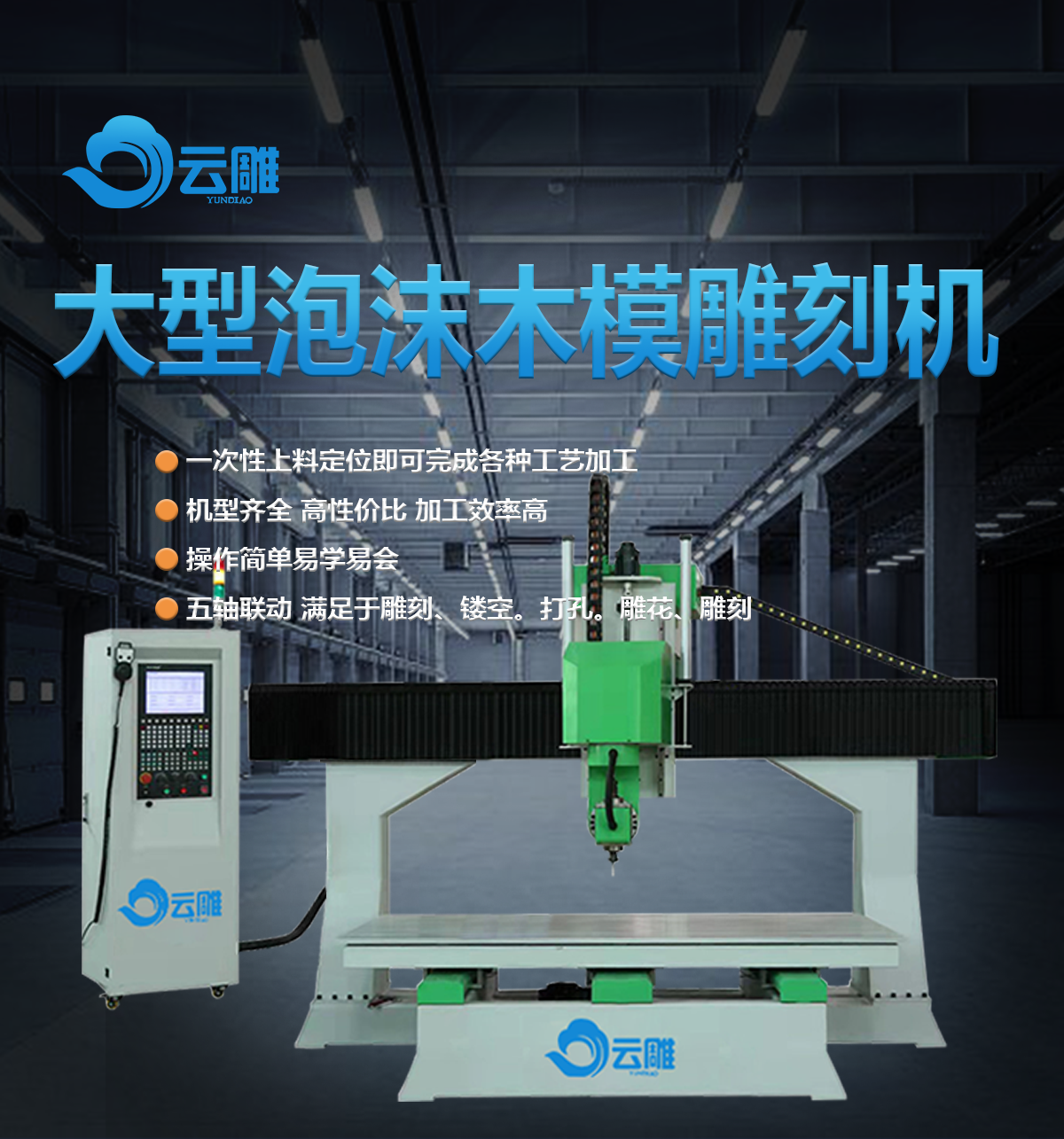

Yundiao Composite Material processing Center, a high-end equipment integrating advanced technology and exquisite technology. The center adopts a sawing machine design, which integrates multiple functions of sawing and processing, greatly improving production efficiency. What is more striking is that its five-axis linkage technology can realize the accurate processing of complex space surfaces, whether it is a plane or a three-dimensional structure, it can be easily dealt with.

In terms of operation, the cloud carving composite material processing center shows great convenience. Programming free design, so that users do not need to have professional programming knowledge, can easily get started, greatly reducing the difficulty of operation. At the same time, the display in front of the device displays the processing information in real time, so that users can intuitively understand the processing progress and status, and further improve the convenience of operation.

From the appearance point of view, the overall color scheme of cloud carving composite material processing center is green and white, giving people a fresh and technological feeling. The mechanical arm and sensor layout are reasonable to ensure the accuracy and stability of the processing. The doors and walls in the background, as well as the words on the walls, although not clear, but also vaguely feel that this is a manufacturing environment full of high-tech atmosphere.

In general, with its sawing all-in-one machine design, five-axis linkage technology and no-programming operation, Yundiaoke composite processing Center has undoubtedly shown a strong competitiveness in the field of composite processing. Whether it is for the pursuit of efficient production enterprises, or for users who care about product quality, it is a trusted choice.

Yundiao five-axis blister cutting machining center is an advanced processing equipment integrating high precision, high efficiency and multi-functionality, which is designed for the complex processing of blister materials and other non-metallic materials. It is widely used in blister molds, furniture manufacturing, bathroom industry, composite material processing and other fields, especially suitable for carving, hollowing, cutting, grinding and other processes of complex curved surfaces.

Key features

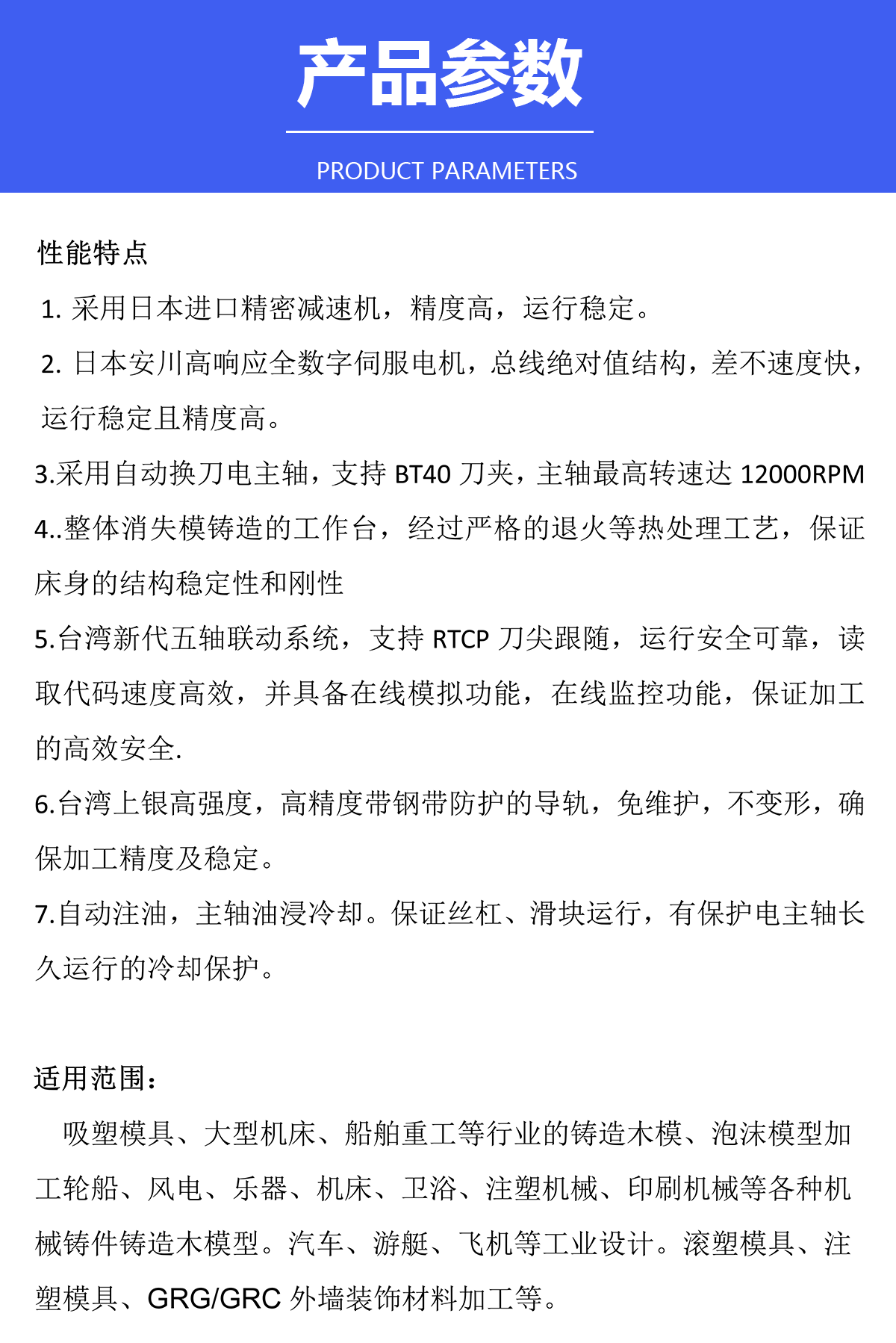

1. High-precision machining

Machining accuracy:It can achieve the accuracy error of the machine tool from 0.03mm to 0.05mm, and the repeated positioning accuracy can reach 0.05mm to ensure the accuracy requirements of the machined parts.

RTCP function:It supports RTCP (Tip Following) technology to achieve true five-axis linkage to ensure the accuracy and stability of the machining process.

2. High-efficiency processing

Processing speed:Up to 50,000 m/min blank line speed and 25,000 m/min (the exact value may vary depending on the model), greatly improving production efficiency.

Automatic tool change:It is equipped with a high-power automatic tool change spindle to realize the free switching of cutting and punching, and improve the equipment utilization rate and production efficiency.

3.Versatility

Five-axis linkage:It supports the linkage control of X, Y, and Z axes and A, B (or C) two rotation axes, and realizes all-round machining without dead angles.

Processing function:It has a variety of functions such as surface engraving, hollowing, drilling, chamfering, trimming, slitting, grinding, etc., which is suitable for a variety of processing needs.

4.Stable and durable

Bed structure:The casting structure or square welded structure is adopted, and the stress relief treatment is used to ensure that it will not be deformed for long-term use.

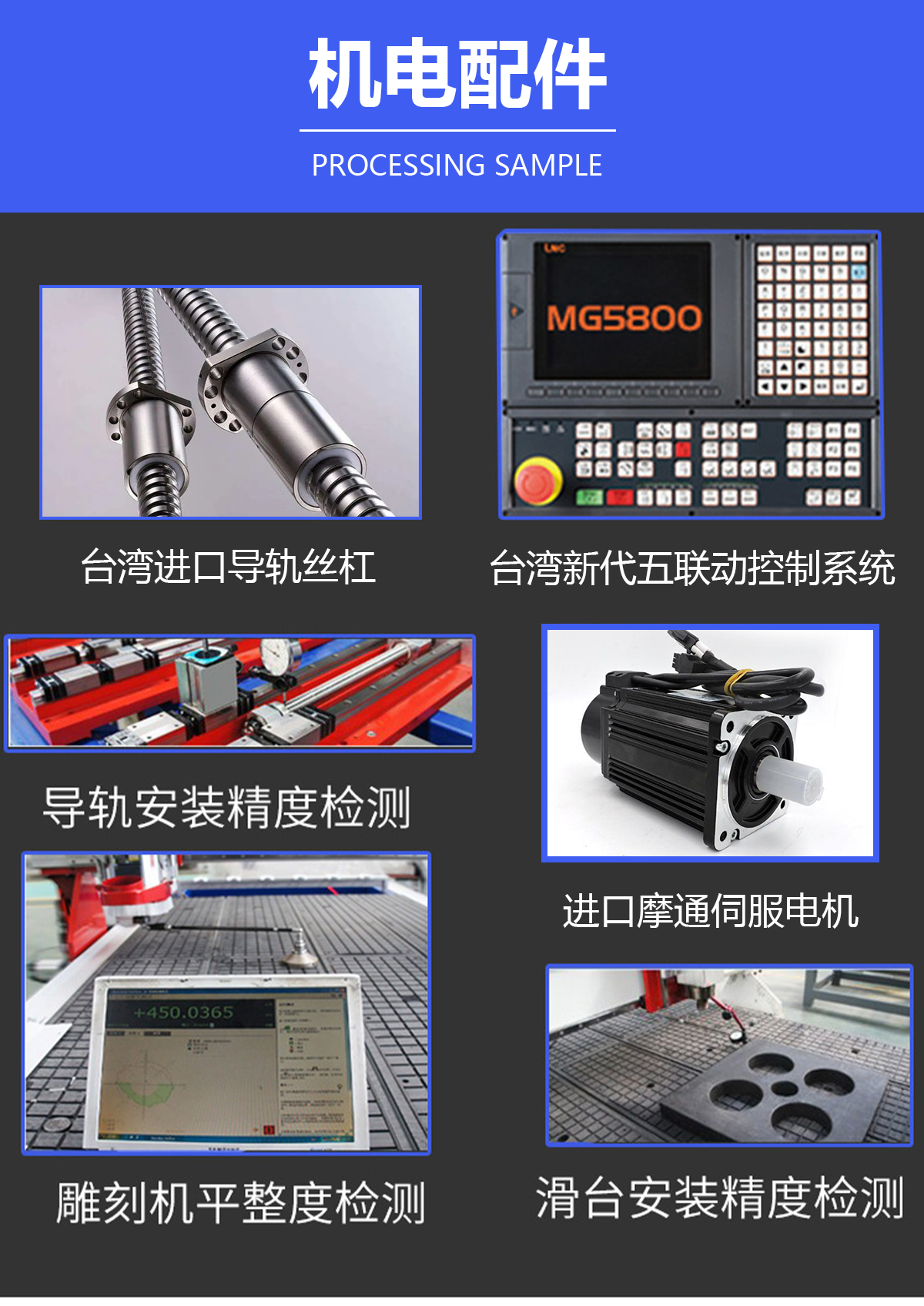

Transmission components:High-precision transmission components, such as Taiwan TBI super-strength linear guides, roller screws, and Japan Xinbao planetary reducers, etc., are used to improve the stability and durability of the equipment.

With its high precision, high efficiency, versatility and stable and durable characteristics, Yundiao five-axis blister cutting machining center has shown strong competitiveness in the processing field of blister materials and other non-metallic materials. Whether in terms of machining accuracy, processing speed or processing range, it can meet the high requirements of modern manufacturing industry. At the same time, the equipment also has the advantages of easy operation and maintenance, providing users with more convenient and efficient processing solutions.

Related products