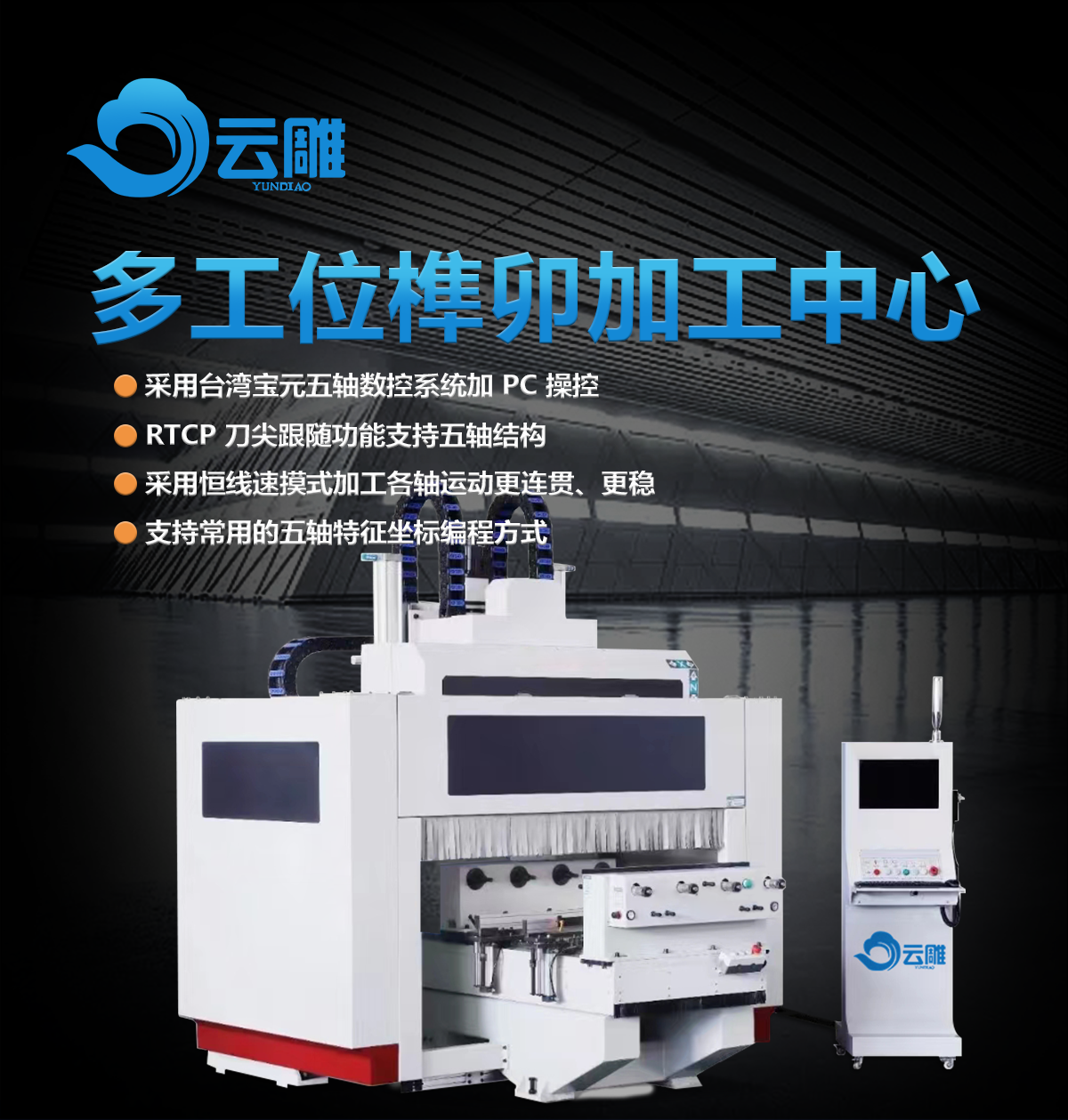

Five-axis mortise and tenon machining center, multi-head switching processing efficiency is twice the result with half the effort

Adopt Taiwan Baoyuan five-axis numerical control system plus PC control, RTCP tip following function supports five-axis structure; The workpiece can be CNC programmed, the tip follows the control function, and the tip always follows the path planned by the NC program

Product characteristics:

Category:

Five axis engraving machine

Product attachments:

Keyword:

Five-axis mortise and tenon machining center, multi-head switching processing efficiency is twice the result with half the effort

contact us

Product Description

Cloud carving four working station car milling composite five-axis processing

Center configuration table and technical parameters

Equipment name: Multi-functional five-axis machining Center: Model: YD-1218

1. Processing range:

Effective machining stroke of X axis; 700mm. Y axis; 1200mm. Z axis; 500mm.

2. Maximum comprehensive operation comprehensive speed; 40M / min

3. Maximum processing speed; 20M / min

4. Clamp; 360° rotary car milling fixture.

5. 1 group of material board (2).

6. CNC system; Taiwan Baoyuan CNC system with PC control, RTCP tip follow function support

Holding a five-axis structure;

7. Servo drive: bus servo, holding EtherCAT and CANopen bus communication;

8. Drive mode:

X-axis precision grinding wire rod, (high precision, low noise)

Z-axis precision grinding wire rod, (high precision, low noise)

9. Body structure; heavy steel structure welding, after 600 degrees of high temperature tempering, vibration to eliminate stress,

Long time using stable without deformation.

10. Tool shaft spacing; 260mm

11. Cooling mode of the spindle motor: the high-voltage fan positioning and cooling system.

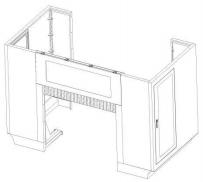

12. Dust removal mechanism: fully coated, the conveyor belt collects wood bran, vacuum mouth diameter of 150 mm * 1.

13. Transmission configuration: German brand precision heavy-duty guide rail.

14. Tool shaft rotation mechanism: using high precision RV reducer.

15. Total power: 43KW.

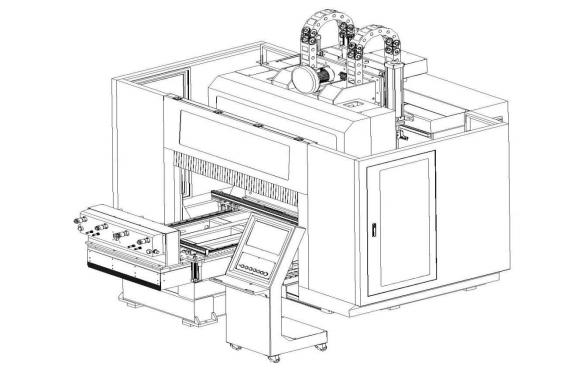

Equipment photo:

Configuration instructions

1. CNC system;

A. Using Taiwan Baoyuan five-axis CNC system and PC control, RTCP tip follow function supports the five-axis structure; CNC can be programmed for the workpiece, the tip follows the control function, the tip is always processed along the path planned by NC program;

B. When using the constant line speed touch processing, the cutting speed of the tool relative to the surface of the workpiece remains constant, and the movement of each axis is more coherent and stable;

C. Processing workpiece surface knife pattern is consistent, the knife path is more delicate, can greatly improve the surface finish and processing quality;

d. Support the common five-axis feature coordinate programming mode, convenient for customers based on the plane programming processing;

E. Servo motor, drive EtherCAT and CANop en bus communication; frequency converter adopts international famous brand, realize high performance precision positioning control, meet the high precision positioning control and stable low speed operation.

2. Control lines: all control lines of the equipment adopt flexible shielding lines, which are anti-interference and has a long service life to ensure the stable operation of the equipment without interference. Electrical components use the French brand Schneider.

3. Processing range:

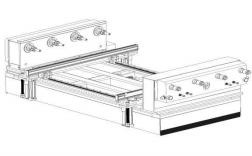

The effective length of the equipment processing is 1,200 mm.4. Fusage structure:

The fuselage is made of national standard 10mm thick steel plate and square tong welding, long time use without deformation, good stability, firm structure, not easy to deformation. After annealing treatment, CNC gantry milling precision machining, drilling, to ensure that each process has high accuracy and stable operation.

5. Equipment transmission structure:

A. Use German brand heavy duty rail slider with stable performance. Linear guide rail, fully meet the high quality product shape processing of the machine strength and accuracy requirements.

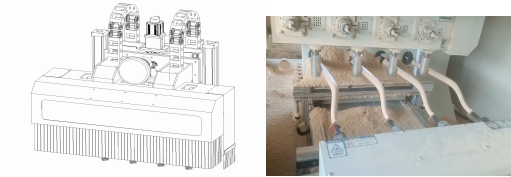

B. Using grinding stage wire rod, high precision, maintenance free, minimal rolling friction, accurate sensitive input, and fine control of small movement. The whole rolling part of the surface of the quenching and hardening treatment, minimal wear, can maintain the initial accuracy, long service life.

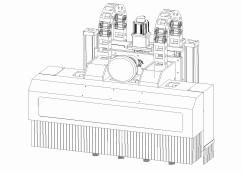

6. B axis adopts high precision RV reducer, with high accuracy and stable performance. All the bearings used in the equipment use the international brand of high-speed bearings. Improve the stability and service life of the equipment.

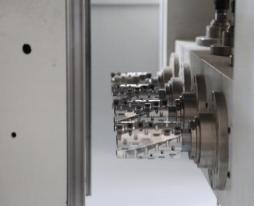

7, double-head knife spindle: high power, large torque, spindle spacing: 260MM. The spindle box is made of special aluminum profile after aging treatment, large hardness, good rigidity. Good surface finish, light quality, good strength characteristics. Reducing the inertia during the fast displacement, the high speed displacement of the spindle box can be realized.

8. Cooling system: the high pressure cooling system is adopted to ensure that the spindle temperature is within the normal range, with long service life and low failure rate.

9. A-axis reducer, servo: using the international brand precision RV reducer. Using 1 kilowatt absolute value servo motor, high positioning precision, high power, heavy cutting processing stability.

11. Reinforced mobile workbench, stable and durable without deformation. The mobile sliding structure of the worktable adopts precision line and rail, which has flexible movement and saves the adjustment time.

12. Fixture group; 360° rotating car milling fixture, the first domestic patent, the maximum processing length of 1200mm., suitable for primary processing of 360° processing products, this fixture can achieve automatic rotation, simple, efficient, save processing steps, milling, groove, drilling once complete. For example, round tables, sofa legs and so on.

12. Fixture group; 360° rotating car milling fixture, the first domestic patent, the maximum processing length of 1200mm., suitable for primary processing of 360° processing products, this fixture can achieve automatic rotation, simple, efficient, save processing steps, milling, groove, drilling once complete. For example, round tables, sofa legs and so on.

13. Adopt high strength drag chain, using high strength flexible drag chain line, comprehensive protection measures, good line isolation effect, to prevent interference. Ensure the stable operation of the equipment.

14. Dust collection method:

16. Dust removal mechanism: fully coated type (optional), conveyor belt collection of wood bran, vacuum suction mouth diameter

100mm * 1 of each one.

15. Guide rail and wire rod lubrication can be adjusted by microcomputer for automatic quantitative and regular oil injection. Make sure that every lubrication area works properly.

The five-axis mortise and tenon machining center is a CNC machining equipment integrating high precision, high efficiency and versatility, which is specially used to process the complex mortise and tenon structure processing in solid wood furniture and other wood products. It is mainly used in the fields of solid wood furniture manufacturing, ancient building restoration, wood carving artwork and so on. Processing of a variety of complex mortise and tenon structures, including a variety of mortise and tenon types in classical furniture, such as dovetail tenons, box tenons, finger jointed tenons, etc.

Technical features

1. Five-axis linkage

Equipped with a five-axis control system, it realizes the linkage control of three linear axes of X, Y and Z and two rotation axes of A, B (or C), which is suitable for processing three-dimensional curved surfaces and complex mortise and tenon structures.

-RTCP (Tip Following) function ensures that the tool always moves along a predetermined trajectory during the machining process, improving machining accuracy.

2. High-precision machining

The CNC positioning system precisely controls the position of the tool, and the machining accuracy can reach a very high level, ensuring that the mortise and tenon structure is tightly integrated and durable.

The processing error is small, the surface finish is high, and it meets the manufacturing requirements of high-end solid wood furniture.

3. High efficiency production

The automatic tool change system reduces the tool change time and improves the processing efficiency.

Multiple processing tasks can be handled at the same time for uninterrupted production.

4. Versatility

In addition to mortise and tenon machining, it can also perform a variety of machining operations such as surface milling, grooving, and drilling.

Supports a wide range of materials, including solid wood with different hardness and densities.

5. Easy to operate

The CNC operating system simplifies the operation process, and ordinary workers can get started with training to operate.

The processing parameters can be directly set and adjusted by the CNC system to reduce human error.The five-axis mortise and tenon machining center has been successfully applied to many solid wood furniture manufacturing enterprises, especially in the fields of mahogany furniture and classical furniture. The furniture processed by this equipment not only has a stable structure and beautiful appearance, but also significantly improves production efficiency and reduces manufacturing costs. An important piece of equipment in the solid wood furniture manufacturing industry, it has won wide recognition in the market for its high precision, high efficiency, versatility and easy operation.

last page

next page

Related products